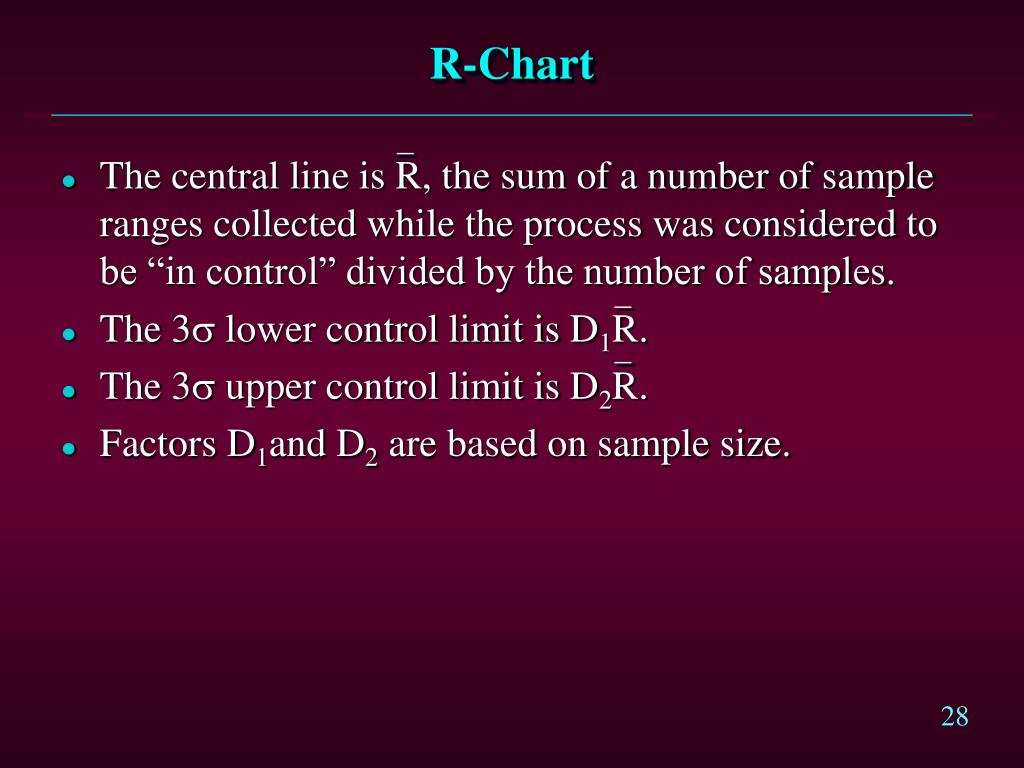

R Chart Formula

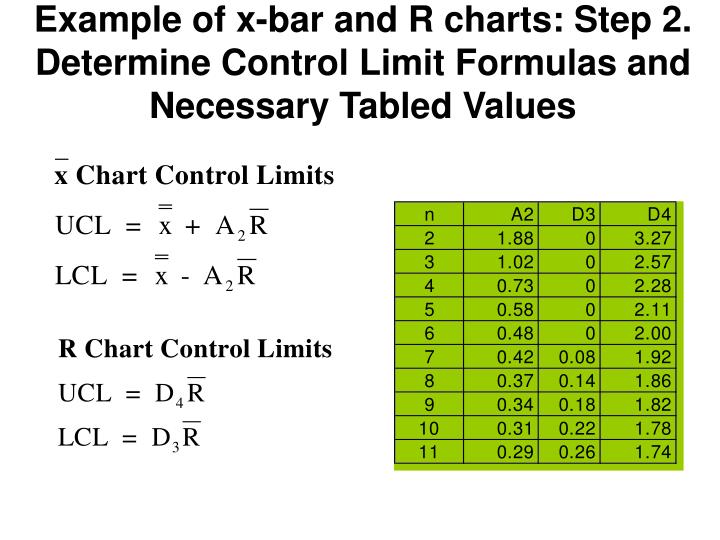

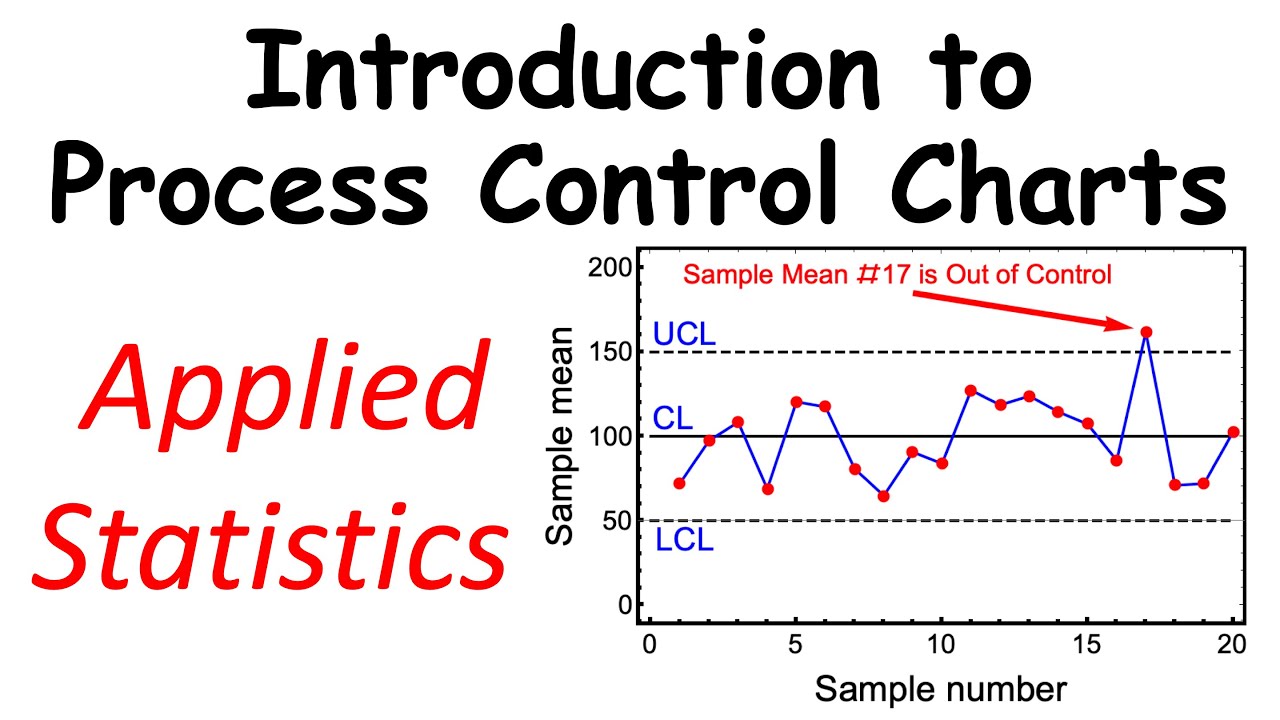

R Chart Formula - Select the method or formula of your choice. If the r chart is out of control, then the control limits on the xbar. The and r chart plots the mean value for the quality characteristic across all units in the sample, , plus the range of the quality characteristic across all units in the sample as follows: The value is 3 for analyses that do not allow custom values.) σ. Web below are the x bar r chart formula that used in the qi macros for both range & avg (xbar) charts. If each set of n rows represents a group, enter the. Is your process in control? C chart for count of defects. P chart for proportion of defective units. Web the r chart is used to evaluate the consistency of process variation. If the subgroup size is one, the. Lc lr = d3 ¯r l c l r = d 3 r ¯. The chart actually consists of a pair of charts: U chart for rate of defects. Web let \(r_1, \, r_2, \, \ldots, r_k\), be the ranges of \(k\) samples. = average of the moving ranges. Is your process in control? U c lr = d4 ¯r u c l r = d 4 r ¯. C chart for count of defects. Look at the r chart first; We can supply a vector or matrix to this function. Lc lr = d3 ¯r l c l r = d 3 r ¯. Web the control chart basics, including the 2 types of variation and how we distinguish between common and special cause variation, along with how to create a ra. Look at the r chart first; Is your. $$ then an estimate of \(\sigma\) can be. Is your process in control? The and r chart plots the mean value for the quality characteristic across all units in the sample, , plus the range of the quality characteristic across all units in the sample as follows: 9/16/2013 2013 by statpoint technologies, inc. Subgroups should be formed to minimize the. U chart for rate of defects. The chart actually consists of a pair of charts: $$ then an estimate of \(\sigma\) can be. Is your process in control? Lc lr = d3 ¯r l c l r = d 3 r ¯. Web the r chart is used to evaluate the consistency of process variation. Web let \(r_1, \, r_2, \, \ldots, r_k\), be the ranges of \(k\) samples. U chart for rate of defects. The xmr chart is a great statistical process control (spc) tool that can help you answer this question, reduce waste, and increase. 9/16/2013 2013 by statpoint technologies,. C chart for count of defects. Parameter for test 1 (the default value is 3 for analyses that allow custom values. This causes the x chart. Look at the r chart first; Web the control chart basics, including the 2 types of variation and how we distinguish between common and special cause variation, along with how to create a ra. Look at the r chart first; Lc lr = d3 ¯r l c l r = d 3 r ¯. Subgroups should be formed to minimize the amount of variation within a subgroup. Parameter for test 1 (the default value is 3 for analyses that allow custom values. 9/16/2013 2013 by statpoint technologies, inc. The chart actually consists of a pair of charts: Subgroups should be formed to minimize the amount of variation within a subgroup. = average of the moving ranges. One to monitor the process standard deviation (as approximated by the sample moving range) and another to monitor the process mean, as is done with the $${\displaystyle {\bar {x}}}$$ and s and. C chart for count of defects. In the formulas above, you see mention of the constants a2, d4,. One to monitor the process standard deviation (as approximated by the sample moving range) and another to monitor the process mean, as is done with the $${\displaystyle {\bar {x}}}$$ and s and individuals control charts. If we supply a vector, the plot. In the formulas above, you see mention of the constants a2, d4,. Web r = the absolute value of the difference between successive pairs of measurements. = average of the moving ranges. One to monitor the process standard deviation (as approximated by the sample moving range) and another to monitor the process mean, as is done with the $${\displaystyle {\bar {x}}}$$ and s and individuals control charts. The xmr chart is a great statistical process control (spc) tool that can help you answer this question, reduce waste, and increase. Web the control chart basics, including the 2 types of variation and how we distinguish between common and special cause variation, along with how to create a ra. If the subgroup size is one, the. C chart for count of defects. U c lr = d4 ¯r u c l r = d 4 r ¯. For a sample size, n, of less than 7 the lower limit is zero. Is your process in control? The and r chart plots the mean value for the quality characteristic across all units in the sample, , plus the range of the quality characteristic across all units in the sample as follows: The average range is $$ \bar{r} = \frac{r_1 + r_2 +. Web the r chart is used to evaluate the consistency of process variation. If we supply a vector, the plot will have bars with their heights equal to. P chart for proportion of defective units.

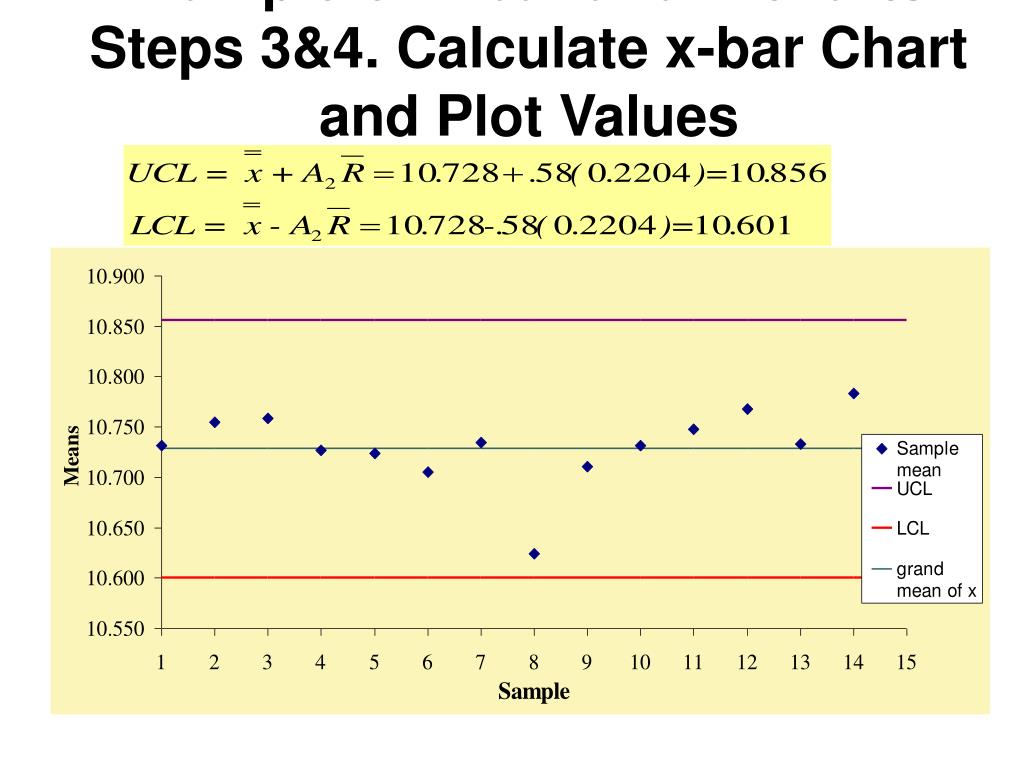

PPT X AND R CHART EXAMPLE INCLASS EXERCISE PowerPoint Presentation

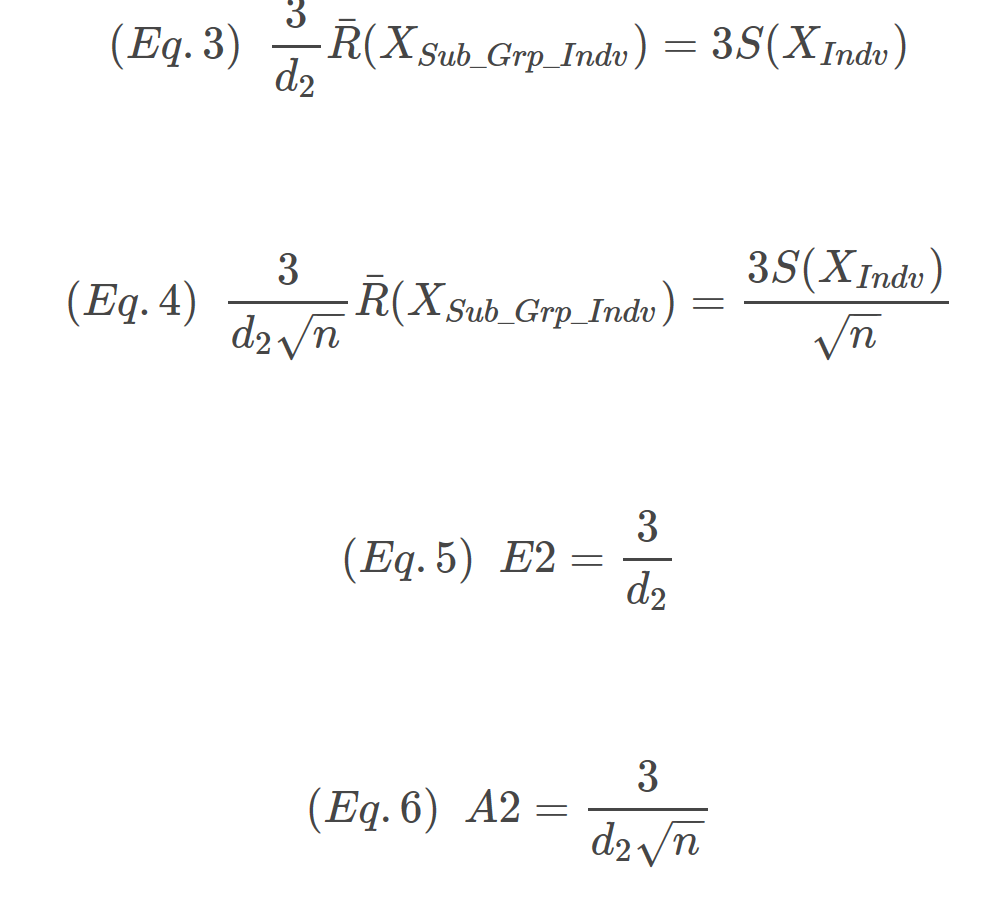

Estimating Control Chart Constants with R

What is common to each of the formulas on the xbar and rcharts. On

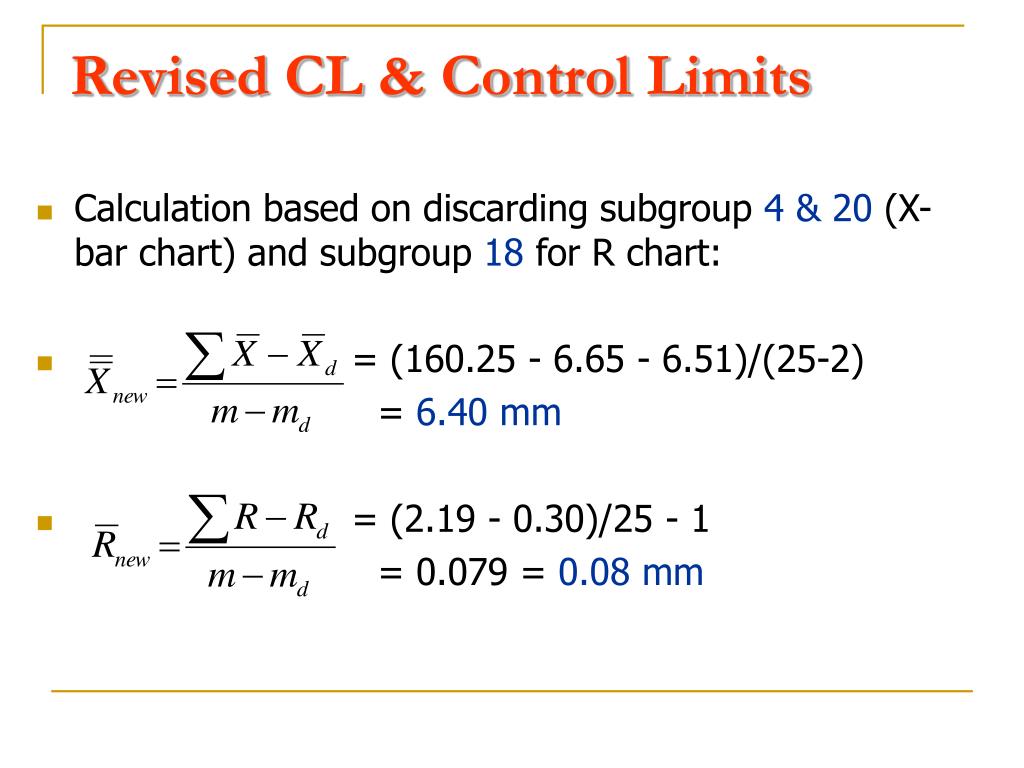

Xbar and R Chart Formula and Constants The Definitive Guide

PPT Control Charts for Variables PowerPoint Presentation, free

PPT Chapter 17 PowerPoint Presentation, free download ID5953193

PPT X AND R CHART EXAMPLE INCLASS EXERCISE PowerPoint Presentation

Xbar And R Chart Formula And Constants The Definitive vrogue.co

How to plot xbar and r bar chart in excel crosspasa

Statistical Process Control Charts for the Mean and Range X Bar Charts

Web Bar Plots Can Be Created In R Using The Barplot() Function.

If The R Chart Is Out Of Control, Then The Control Limits On The Xbar.

If Each Set Of N Rows Represents A Group, Enter The.

Web Let \(R_1, \, R_2, \, \Ldots, R_K\), Be The Ranges Of \(K\) Samples.

Related Post: