Ra Roughness Chart

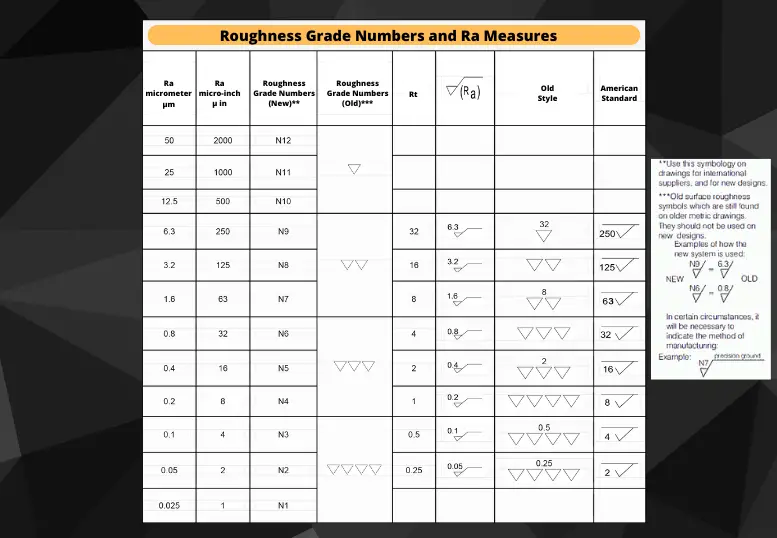

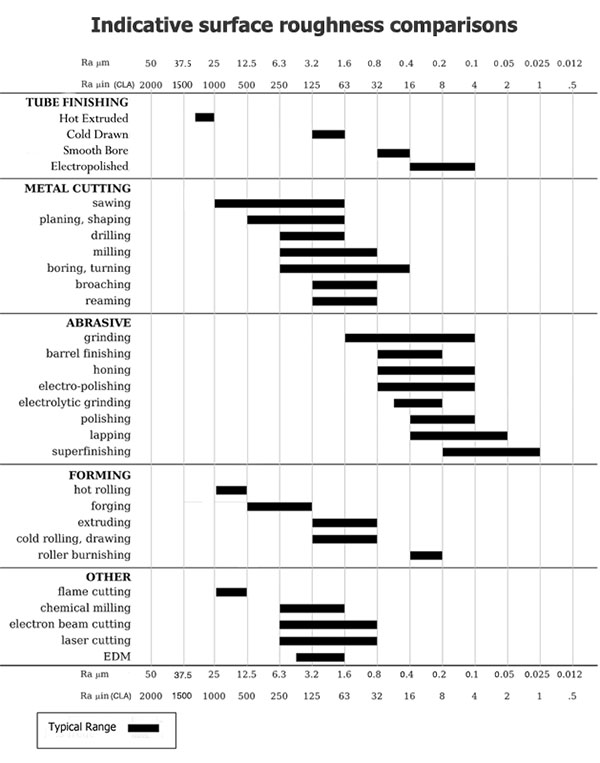

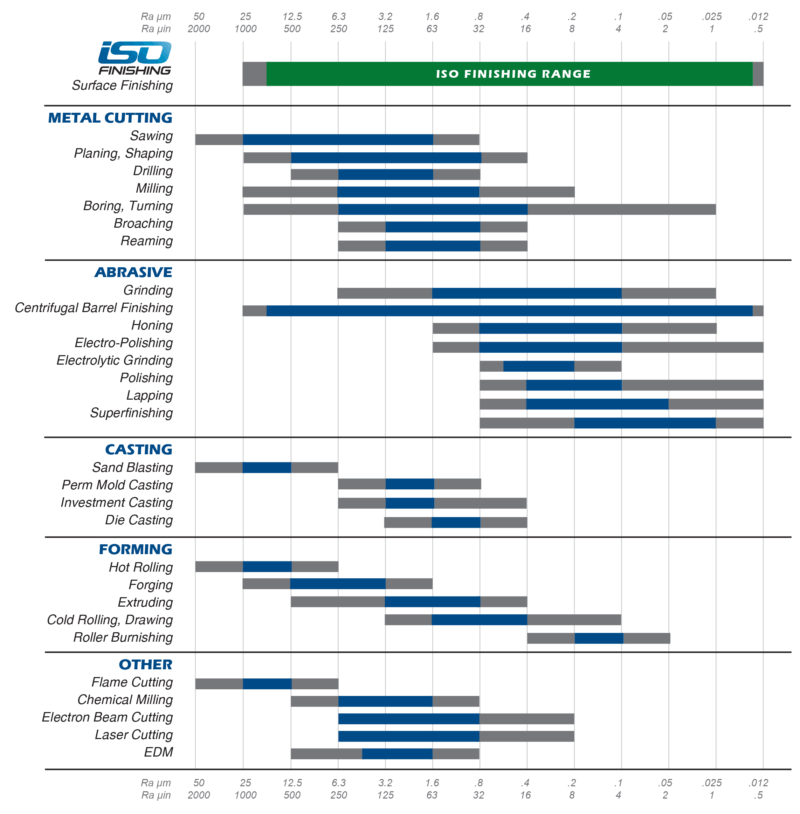

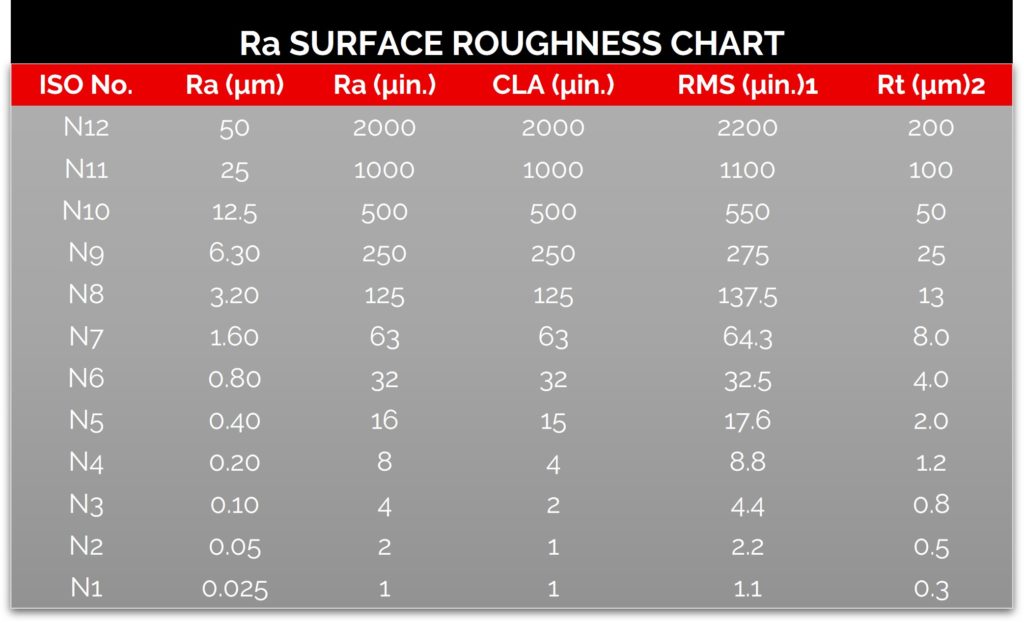

Ra Roughness Chart - The mean arithmetical value “ra” in μm is assumed for roughness measurements. Web what differentiates ra and rz in the surface roughness chart? We will break down the key elements of the chart and explain how different ra values correspond to surface qualities ranging from smooth to rough textures. Web what differentiates ra and rz in surface roughness chart? Ra represents the average distance between peaks and valleys. Check how injection moulding surface finish can be defined and used as a functional or aesthetical feature. Surface roughness is a measure of the texture of a surface. Web the ra chart serves as a visual reference to categorize surface finishes based on ra values. Web this resource will share ways to measure and compare surface roughness in cnc machined parts, extrusions, moulding, casting and 3d printing, as well as standard surface finishes to expect. See how iso finishing compares to common metal manufacturing practices. If these deviations are large, the surface is rough; Mean line is the reference line about which the roughness profile deviations are measured. Hover with the mouse over the chart to get the feedrate that gives your required ra. Web the ra chart provides a graphical representation of surface roughness measurements. It is the average roughness in the area between. Ra ranges and corresponding surface finishes. Web surface roughness conversion charts and tables, definitions and data. Web the ra chart serves as a visual reference to categorize surface finishes based on ra values. It also measures the deviation from the mean line on the surface within a sampling length. Web what differentiates ra and rz in the surface roughness chart? By understanding and interpreting this chart, manufacturers can make informed decisions regarding machining processes and material selection. Surface roughness average ra vs manufacturing process. If they are small, the surface is smooth. Graphically, ra is the area between the roughness profile and its centerline divided by the evaluation. Web surface finish units from ra to rz. Web surface finish units from ra to rz. Surface roughness average ra vs manufacturing process. Web what differentiates ra and rz in surface roughness chart? Web ra (average surface roughness) is a unit for measuring surface finish, and it is also referred to as center line average or arithmetic average. Ra parameter computes the mean line average roughness of the. Web surface finish units from ra to rz. It provides a visual guide to different surface finishes, with notations and surface roughness values. Check how injection moulding surface finish can be defined and used as a functional or aesthetical feature. It is the average roughness between a roughness profile and the mean line. Hover with the mouse over the chart. It is quantified by the vertical deviations of a real surface from its ideal form. Ra is also known as arithmetic average (aa) or center line average (cla). There are wide ranging variations in finishing and edge conditions. The roughness is usually composed of smaller irregularities, while the waviness consists of larger undulations. Web what differentiates ra and rz in. Ra ranges and corresponding surface finishes. The mean arithmetical value “ra” in μm is assumed for roughness measurements. They are divided into three characteristics, including roughness, waviness, and lay. Web in engineering science and quality assessment, surface roughness is typically measured and characterized using specific parameters such as ra, rz, or rmax (where r is roughness). Web the ra chart. It provides a visual guide to different surface finishes, with notations and surface roughness values. Web surface finish units from ra to rz. We will break down the key elements of the chart and explain how different ra values correspond to surface qualities ranging from smooth to rough textures. The mean arithmetical value “ra” in μm is assumed for roughness. Ra ranges and corresponding surface finishes. Maximum value of roughness from the lowest to the highest point. How to measure surface roughness? Web surface roughness chart units and abbreviations. The mean arithmetical value “ra” in μm is assumed for roughness measurements. If these deviations are large, the surface is rough; It also measures the deviation from the mean line on the surface within a sampling length. Web the surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing processes. Web surface finish units from ra to rz. Web. It is quantified by the vertical deviations of a real surface from its ideal form. Surface roughness is a measure of the texture of a surface. Web roughness is measured in a trasversal direction to the main grooves. We will break down the key elements of the chart and explain how different ra values correspond to surface qualities ranging from smooth to rough textures. Web ra surface finish chart | surface roughness chart. Ra ranges and corresponding surface finishes. It is the average roughness in the area between the roughness profile and its mean line. Surface finishes are measured using averaging or profiling instruments. See how iso finishing compares to common metal manufacturing practices. It is quantified by the deviations in the direction of the normal vector of a real surface from its ideal form. The mean line of the roughness profile is. Listed are some of the more common manufacturing techniques and their corresponding ra surface finish values. Web the surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing processes. It is the average roughness in the area between the roughness profile and its mean line. It also measures the deviation from the mean line on the surface within a sampling length. Check how injection moulding surface finish can be defined and used as a functional or aesthetical feature.

Measured and the Predicted Values of Surface Roughness (Ra and Rz) and

Surface Roughness Ra Chart

Surface Finishing in CNC Machining with Symbols, Charts, RZ,RA

Ra Surface Roughness Chart

Complete Guide to Surface Finish Charts, RA, RZ, Measurements, Callouts

Ra Surface Roughness Chart

Ra Surface Roughness Chart

Surface Roughness Chart Comparison ISO Finishing

Ra Rz Rt Roughness Chart

Surface Finish Chart for Ra Roughness AMF Technologies

The Evaluation Length Comprises Five Sample Lengths Equaling One Cutoff Length.

Benefits Of Utilizing Ra Chart.

Averaging Instruments Cannot Measure Waviness And Typically Display Surface Finish Values On A Meter.

Ra Is Also Known As Arithmetic Average (Aa) Or Center Line Average (Cla).

Related Post: