Ring Gap Chart

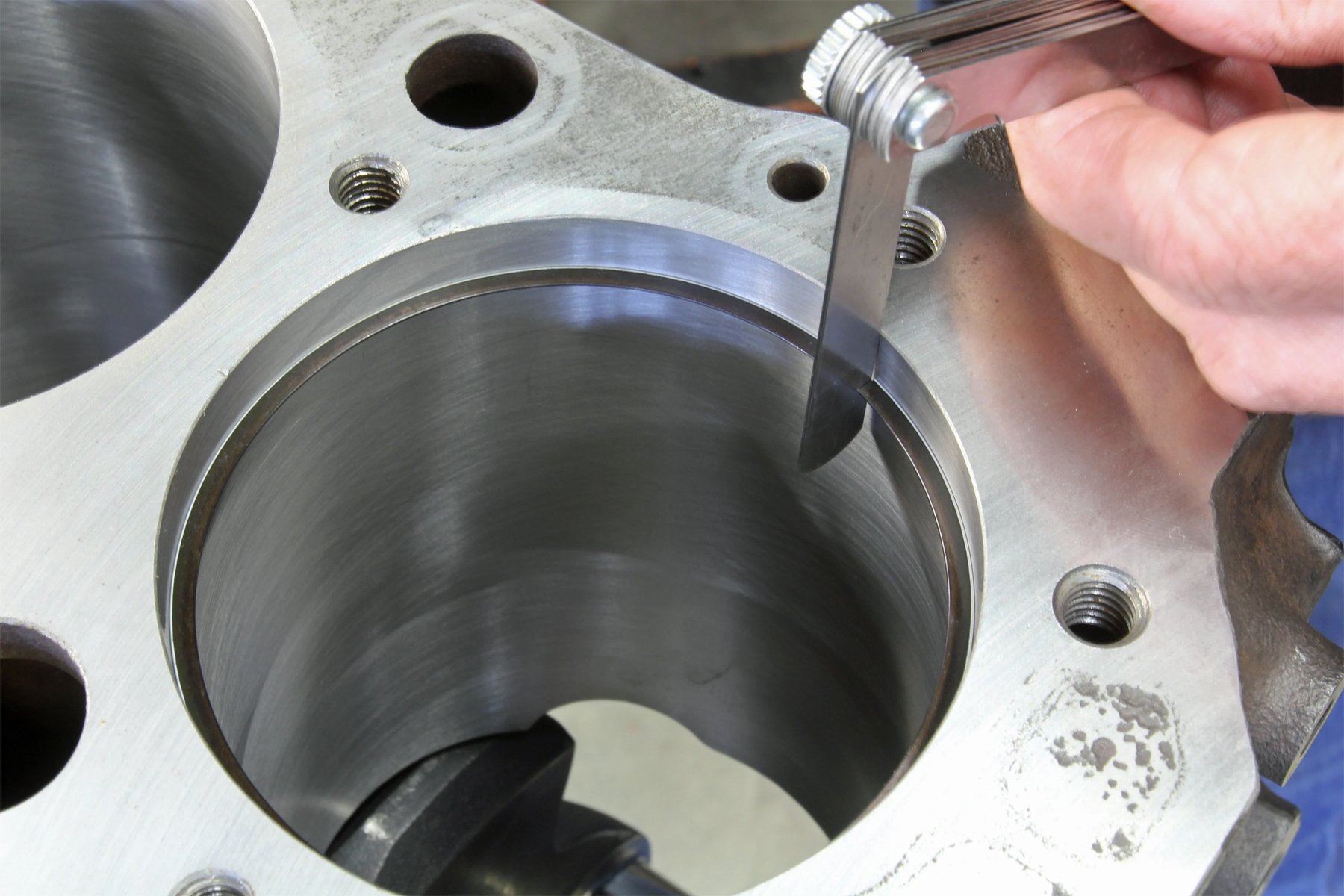

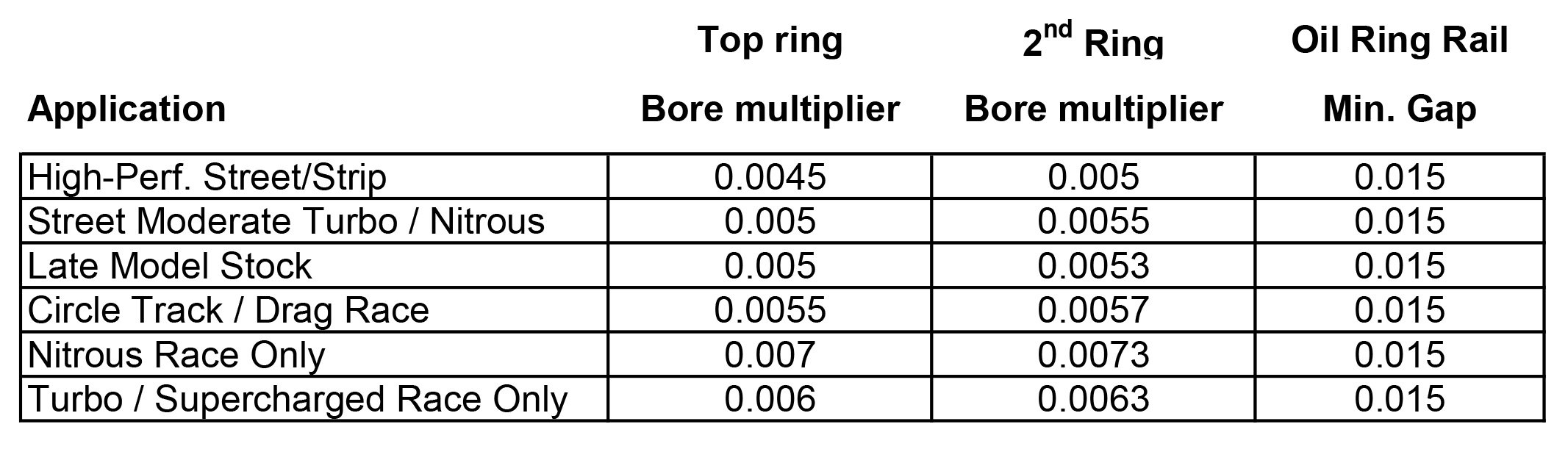

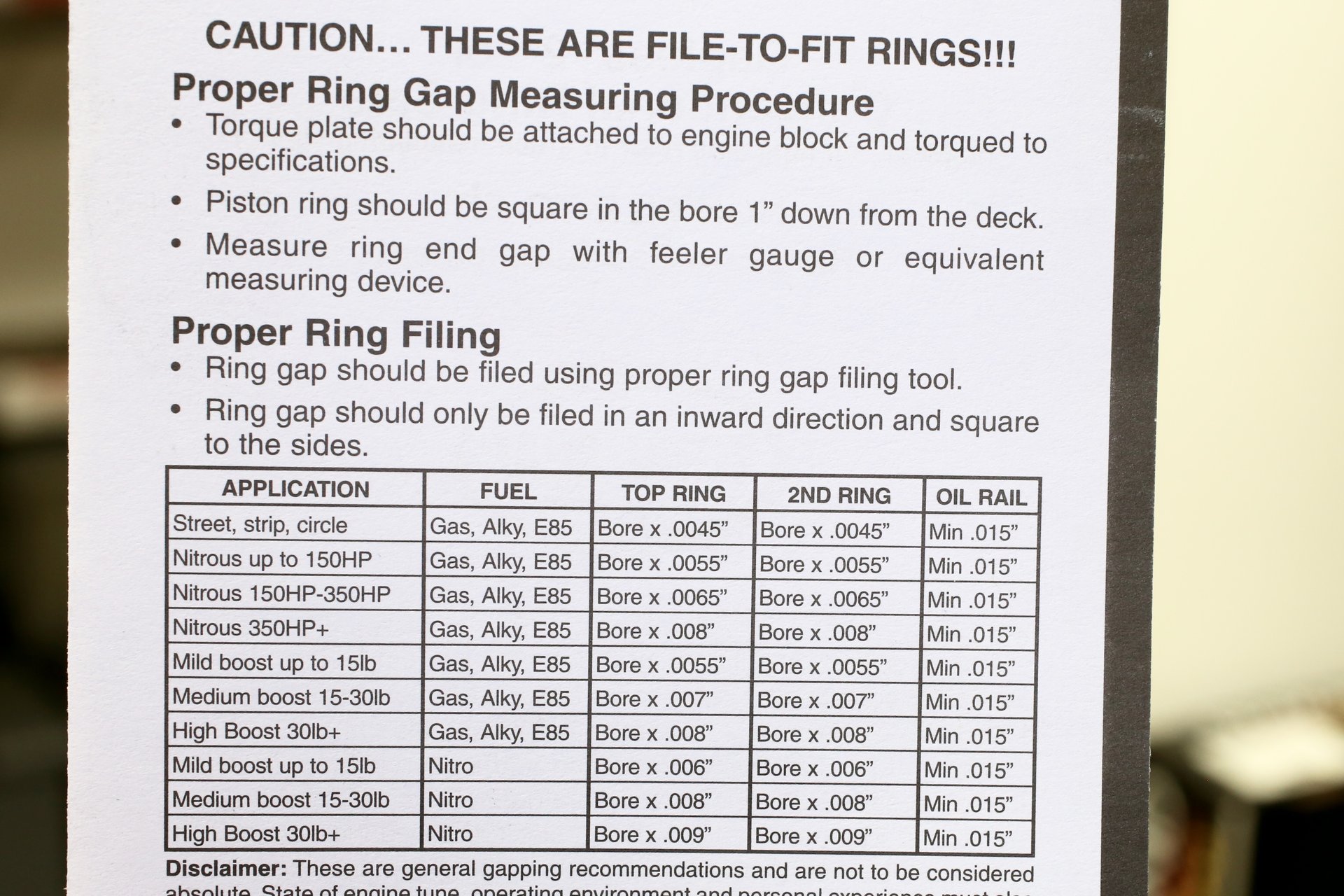

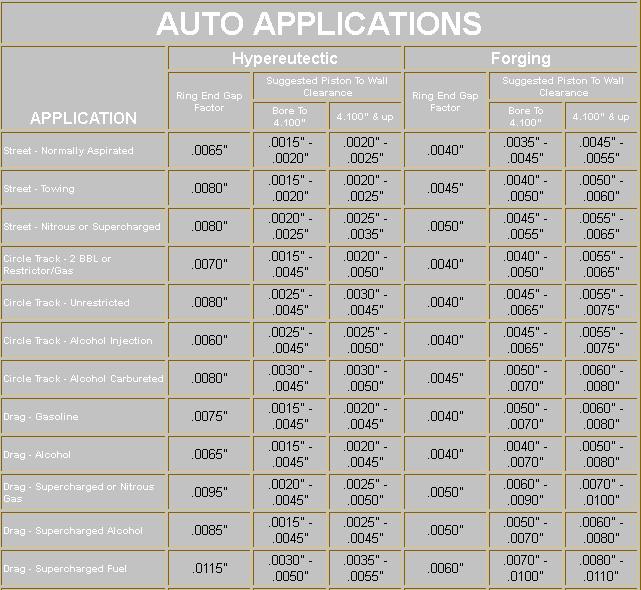

Ring Gap Chart - Calculate the recommended ring end gap from the chart above. Web use a feeler gauge to measure the exact clearance. Cylinder should be free of any taper. Set second ring end gap at.004 per inch of bore minimum. Multiply bore size x ring end gap factor. The second ring end gap would be 4.000 x.0045″ =.018″. A proper ring gap fi ling tool must be used. Use this chart to determine the proper end gap for your engine. Web to properly measure the ring gap, the ring should be square in the bore 1” down from the deck. Web use the chart below to determine the minimum ring end gap. The idea is to run a slightly larger gap for the second ring to prevent a pressure buildup between the top and second ring. Web wiseco piston ring gap quick tips. Web use a feeler gauge to measure the exact clearance. These are based on different user applications. Web to use this chart, multiply the bore size by the ring. These are based on different user applications. Web this means that once installed, they’re good to go. Aluminum expands and contracts with temperature variations. As a piston moves down on the power stroke, combustion pressure accumulates in the land area of the piston (between the top ring and the 2nd ring.) this accumulation of pressure can cause the top ring. These are based on different user applications. Measure the ring end gap with a feeler gauge or equivalent device. Aluminum expands and contracts with temperature variations. Cylinder should be free of any taper. Multiply bore size x ring end gap factor. As a piston moves down on the power stroke, combustion pressure accumulates in the land area of the piston (between the top ring and the 2nd ring.) this accumulation of pressure can cause the top ring to unseat from its sealing area at the bottom of the ring groove. Web use the chart below to determine the minimum ring end. Web ring end gap should be measured with the ring square in the bore on a fresh hone. Web the following chart indicates the specifications for compression ring gap as outlined by the sae (society of automotive engineers) as standards for the automotive piston ring manufacturers. 4.000” bore street engine with cast piston the top ring end gap factor is.004”,. These are based on different user applications. Calculate the recommended ring end gap from the chart above. Web as a general guideline, ring end gap that is larger than expected is less of an operational concern than too little end gap. As a piston moves down on the power stroke, combustion pressure accumulates in the land area of the piston. Multiply bore size x ring end gap factor. Web this means that once installed, they’re good to go. The following is a recommended gap chart for conventional (gap style) rings from total seal piston rings: Use this chart to determine the proper end gap for your engine. Dimensions listed are gauged at a temperature of 68 degrees fahrenheit. Aluminum expands and contracts with temperature variations. Set second ring end gap at.004 per inch of bore minimum. The proper amount of end gap required is directly dependent upon the amount of heat to which the top ring in most cases should be the bore size in inches x.004. Setting custom ring end gaps can be accomplished easily enough. Web. The second ring end gap would be 4.000 x.0045″ =.018″. Cylinder should be free of any taper. These calculations are a general guideline, and your oem service manual will also provide further detail. Is there a measurable power difference between these two. These are based on different user applications. To determine the initial gap, position the ring inside the cylinder near the top of the bore. These pistons need to be installed with the offset to. Calculate the recommended ring end gap from the chart above. Your pistons are manufactured from 4032 high silicon aluminum alloy. Web to properly measure the ring gap, the ring should be square in. Web as a general guideline, ring end gap that is larger than expected is less of an operational concern than too little end gap. These pistons need to be installed with the offset to. Multiply bore size x ring end gap factor. Web to properly measure the ring gap, the ring should be square in the bore 1” down from the deck. Web wiseco piston ring gap quick tips. Set second ring end gap at.004 per inch of bore minimum. These are based on different user applications. Ring end gap should be measured with the ring square in the bore on a fresh hone. As you can see by this chart, boosted nitro engines require much more gap than street engines. The second ring end gap would be 4.000 x.0045″ =.018″. (bore size measured in inches). In this article, we’re going to explore how to select, measure, and adjust your ring end gaps to help achieve a reliable ring seal. A proper ring gap fi ling tool must be used. Ross racing rings for the top and second grooves are oversized and must be file fitted to obtain proper end gap. Web calculating top ring end gap. Many wossner piston have an offset wrist pin.

FM 124 ring gaps Harley Davidson Forums

Proper piston ring gap measurement. GOLFMK7 VW GTI MKVII Forum / VW

Proper Piston Ring Gap Is Crucial For Best Engine Performance

Blueprint Series The How And Why Of Setting Piston Ring End Gap

Ring gap

Piston Ring Gap How Important Is It And How To Get Them Correct

How to FileFit and Install Piston Rings

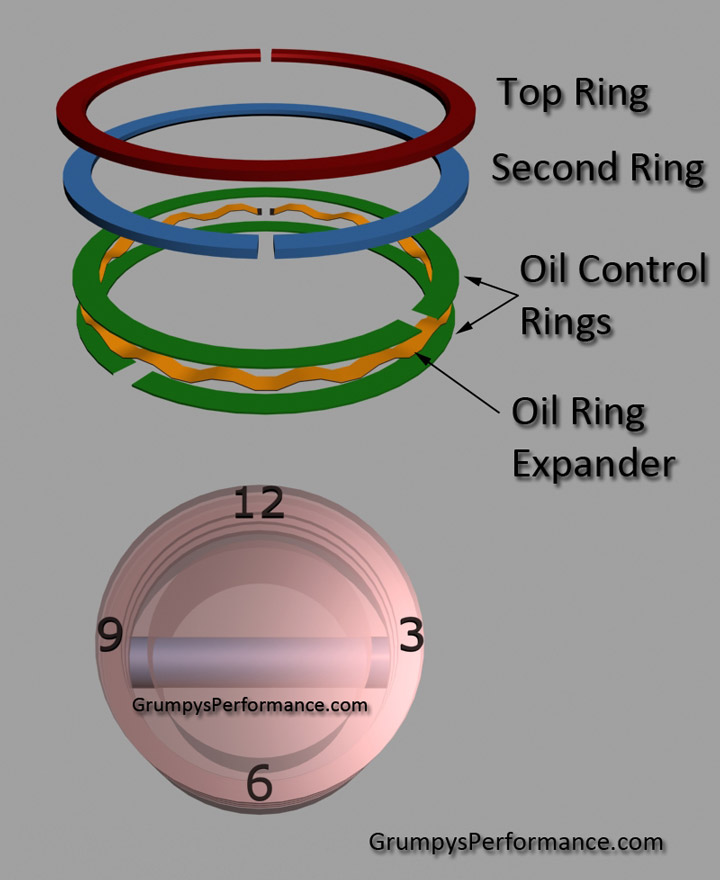

installing rings in piston grooves Grumpys Performance Garage

Piston ring gap chart. Greg Clark Flickr

ring gapping and basic piston ring info YOULL NEED Grumpys

Is There A Measurable Power Difference Between These Two.

Cylinder Should Be Free Of Any Taper.

Web Ring End Gap Should Be Measured With The Ring Square In The Bore On A Fresh Hone.

Dimensions Listed Are Gauged At A Temperature Of 68 Degrees Fahrenheit.

Related Post: