Ring Pinion Pattern Chart

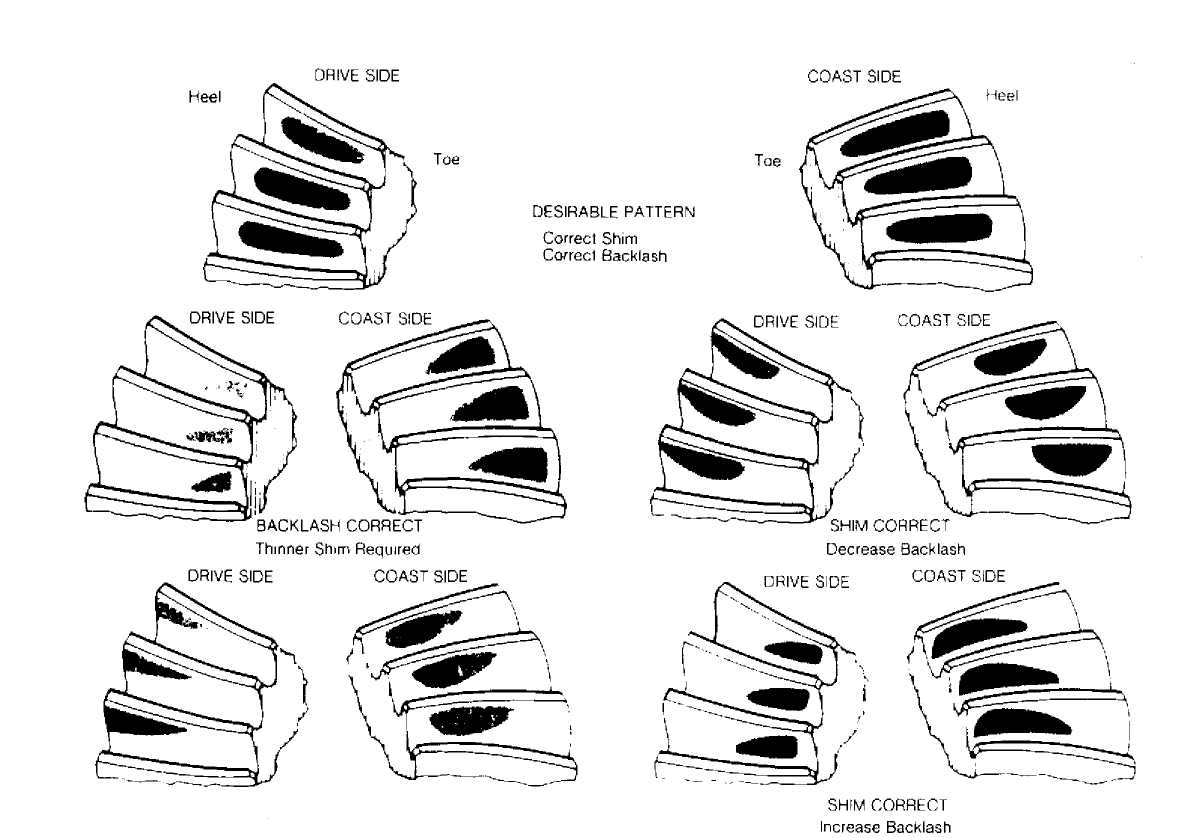

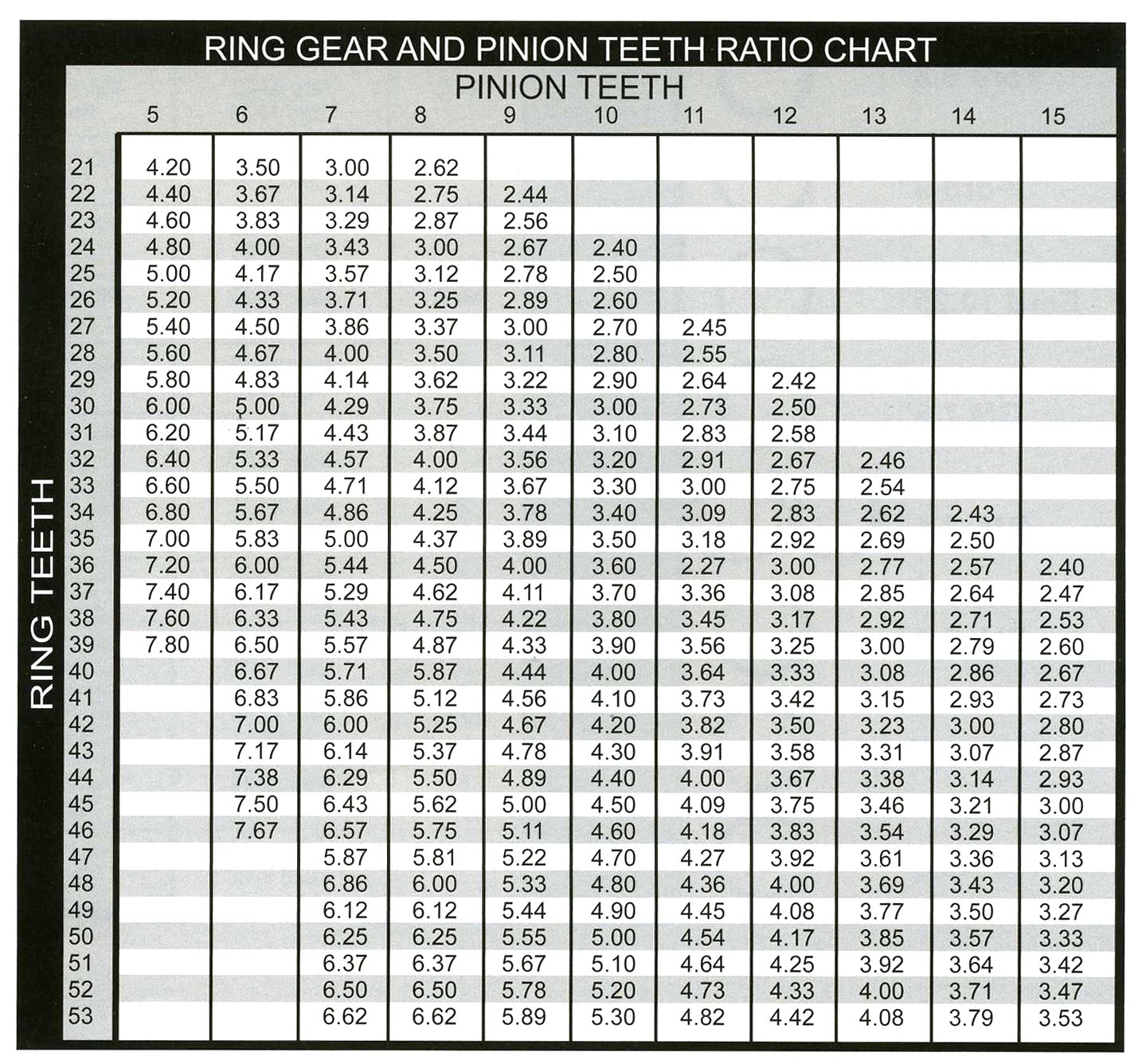

Ring Pinion Pattern Chart - Gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous. Ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set. 3,000 rpm /3.73= 804 rpm. Web the pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. If you have the backlash set correctly to specifications and you change the pinion position shim,. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending. The following diagrams provided courtesy. Web ring and pinion gear tooth pattern. Web the final pinion position will be verified by using the gear contact pattern method described as follows: Disregard the pattern’s position to the tooth’s heel (ring gear outside. Reading contact patterns can be daunting when looking at the average gear. Web here's how to achieve the best ring & pinion contact pattern , every time, in just 3 simple steps! Web the final pinion position will be verified by using the gear contact pattern method described as follows: Web how to create & read ring gear patterns. 32k. Ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set. Web coast pattern moves deeper on the tooth and toward the heel. 32k views 9 months ago. The toe of the gear is the portion of the tooth surface. The pattern refers to how the ring gear and pinion gears. Is it prematurely worn or chipped teeth? If you have the backlash set correctly to specifications and you change the pinion position shim,. 3,000 rpm /3.73= 804 rpm. Disregard the pattern’s position to the tooth’s heel (ring gear outside. There is a process used when reassembling a differential that optimizes ring gear and. 3) rotate the ring gear in both directions over the painted areas using the pinion yoke to spin it. Is it prematurely worn or chipped teeth? Web last updated on 02/28/2022. If you have the backlash set correctly to specifications and you change the pinion position shim,. Web bearing and carefully tap the pinion seal in place with a properly. There is a process used when reassembling a differential that optimizes ring gear and. (4) thinner pinion position shim with the backlash constant moves the pinion further from the ring gear. Shows how varying pinion depth and back lash a few thousandths of an inch affect ring and pinion pattern. Reading and interpreting gear patterns can be very confusing if. Gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous. The pattern refers to how the ring gear and pinion gears mesh. 276k views 10 years ago. Web coast pattern moves deeper on the tooth and toward the heel. Shows how varying pinion depth and back lash. Web ring and pinion gear tooth pattern. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending. 32k views 9 months ago. Disregard the pattern’s position to the tooth’s heel (ring gear outside. Web the pattern’s position to. Web how to create & read ring gear patterns. There is a process used when reassembling a differential that optimizes ring gear and. (4) thinner pinion position shim with the backlash constant moves the pinion further from the ring gear. Web coast pattern moves deeper on the tooth and toward the heel. Disregard the pattern’s position to the tooth’s heel. Web the pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. When making changes, note that two variables are involved. Web the pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. Web last updated on 02/28/2022. Shows how varying pinion depth and back lash a few thousandths of an inch. Begin by setting proper pinion bearing preload, total turning preload, and. Web how to create & read ring gear patterns. Web the pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. The pattern refers to how the ring gear and pinion gears mesh. 3,000 rpm /3.73= 804 rpm. 276k views 10 years ago. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending. Web the pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. Shows how varying pinion depth and back lash a few thousandths of an inch affect ring and pinion pattern. Begin by setting proper pinion bearing preload, total turning preload, and. Web ring and pinion gear tooth pattern. This chart illustrates different patterns and adjustments. Web i have included two charts here to help you understand and adjust the pattern and backlash. Web the pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. Disregard the pattern’s position to the tooth’s heel (ring gear outside. If you have the backlash set correctly to specifications and you change the pinion position shim,. Or an ominous clunking sound? Web coast pattern moves deeper on the tooth and toward the heel. Is it prematurely worn or chipped teeth? Web last updated on 02/28/2022. The pattern refers to how the ring gear and pinion gears mesh.

Differential Gear Patterns

Ring paint/ pinion IH8MUD Forum

Ring & pinion set up, Jantz Engineering advanced masters course

Ring And Pinion Pattern Patterns Gallery

Incorrect pattern adjust backlash, Incorrect pattern adjust pinion

RING AND PINION TOOTH CONTACT PATTERN...mine with pic MGB & GT Forum

Weber_Ring_Gear_Contact_Pattern_Interpretation.pdf Gear Tooth

How to Read and Interpret Gear Patterns (Ring and Pinion) YouTube

Ring and Pinion Pattern Help! Ford Bronco Forum

Ring and Pinion Gear Ratio Calculation Chart Quadratec

3,000 Rpm /3.73= 804 Rpm.

Web Here's How To Achieve The Best Ring & Pinion Contact Pattern , Every Time, In Just 3 Simple Steps!

Reading Contact Patterns Can Be Daunting When Looking At The Average Gear.

Web Front Axles, So Use The Drive Side For Reading The Pattern.

Related Post: