Sandblasting Media Chart

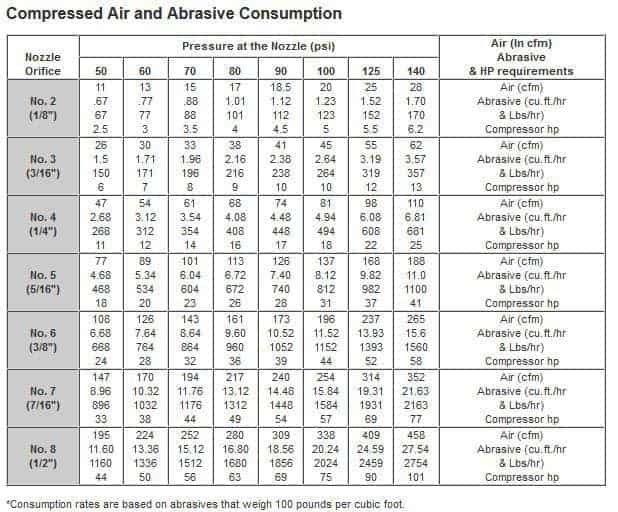

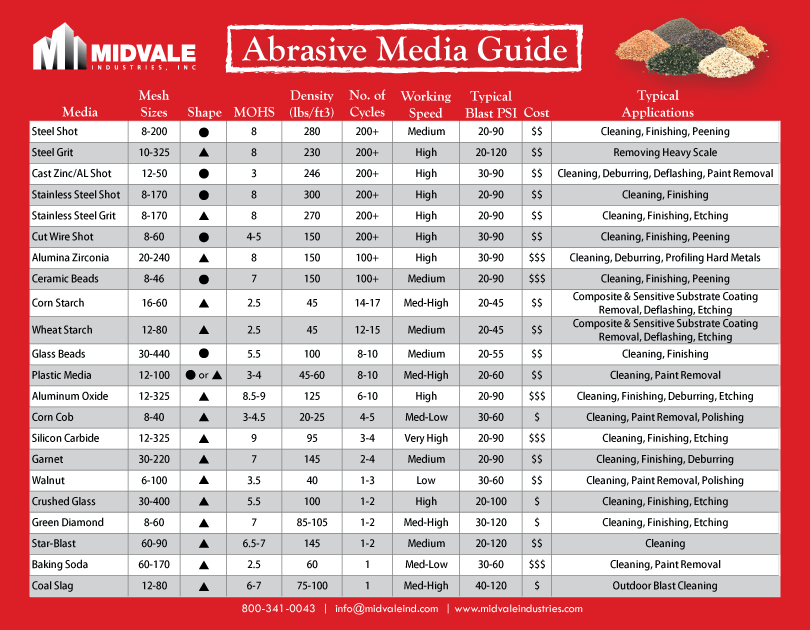

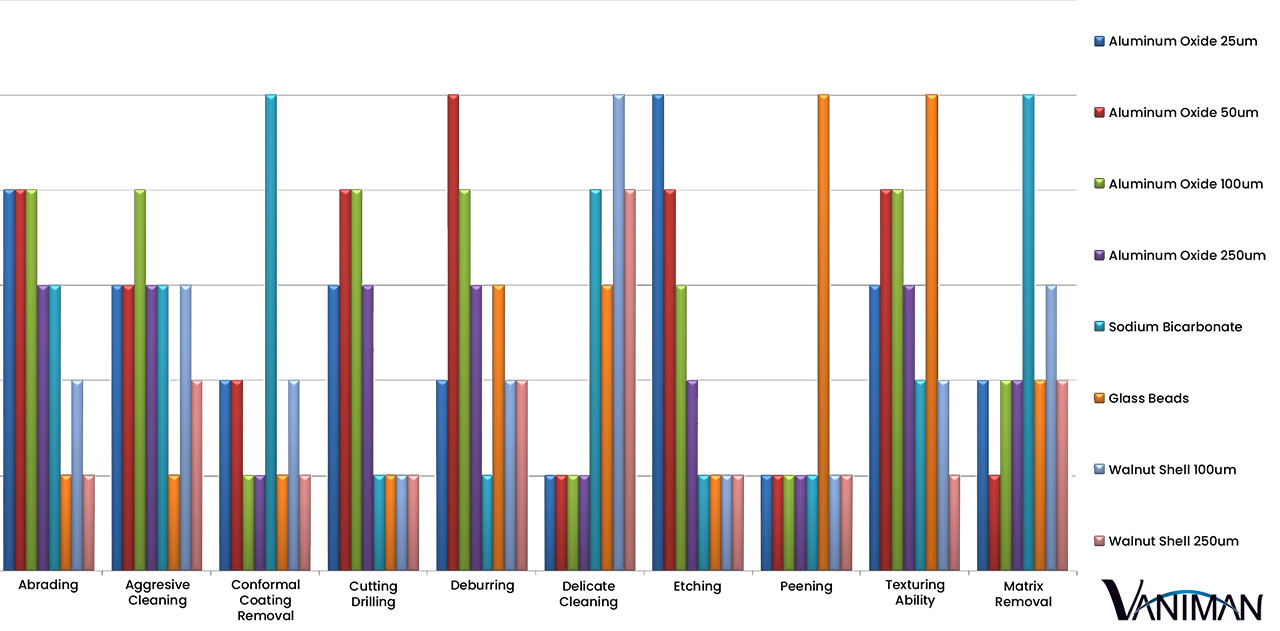

Sandblasting Media Chart - Web media blasting (also called sandblasting or abrasive blasting) has many uses, from removing a layer of paint to deodorizing molded wood beams to removing. Covers glass bead, aluminum oxide, silicon carbide sand & walnut shell. Lower numbers mean larger, while higher numbers mean the particles are more fine. 1 on the chart released may 29. Web picking grit size for sandblasting; Aluminum oxide, steel shot as. Web in this guide, we spell out which common abrasive blast media work best for which materials, from glass beads to walnut shells. Web abrasive blasting media vary dramatically in particle size, hardness, shape, and other properties. Easily see microns to grit size. Focusing on a wide array of sandblast media and also abrasives blast media for cleansing, finishing and surface area prep work. Web the below charts show a few types of abrasive used in dry media blasting. Sandblasting media is the material used in the sandblasting process to remove surface contaminants, smooth out rough surfaces, or etch designs. Easily see microns to grit size. Covers glass bead, aluminum oxide, silicon carbide sand & walnut shell. Aluminum oxide, steel shot as. Web in this guide, we spell out which common abrasive blast media work best for which materials, from glass beads to walnut shells. Surface preparation vs surface cleaning; Web this abrasive sandblasting media tool will help you calculate grit to micron conversion. Use our instant grit to. Lower numbers mean larger, while higher numbers mean the particles are more fine. Web reference chart to which blasting media is best for restoration & stripping what material. Web an abrasive blast media, by definition, are the particles of solid material that cause abrasion and erosion when impacted onto a target material, and there are a lot to choose from!. Web understanding the impact of different abrasives will help in deciding the best. Sandblasting media is the material used in the sandblasting process to remove surface contaminants, smooth out rough surfaces, or etch designs. Learn about the differences and applications of various blasting media, such as aluminum oxide, glass beads, silicon carbide, plastic, pumice, steel shot and more… Web in this guide, we spell out which common abrasive blast media work best for. Web king & prince reign over the billboard japan hot 100 with “halfmoon,” blasting in at no. Web this media is ideal for stripping coatings and paint from substrates, including aluminum and other delicate metals, composites and plastics. Lower numbers mean larger, while higher numbers mean the particles are more fine. 1 on the chart released may 29. The relative. Web the following abrasive blasting media guide will help you through the abrasive selection process. While the common term may be “sandblasting media” or “sand blast. Web understanding the impact of different abrasives will help in deciding the best media for the job. Learn about the differences and applications of various blasting media, such as aluminum oxide, glass beads, silicon. Web the following abrasive blasting media guide will help you through the abrasive selection process. Use our instant grit to. With diy auto restorers in mind, we’ll. Web guide to abrasive blasting media. While the common term may be “sandblasting media” or “sand blast. Web guide to abrasive blasting media. Web material mesh size shape density lbs/ft3 mohs friability initial cost # of cycles per use cost source typical apps sil. Easily see microns to grit size. Surface preparation vs surface cleaning; Use our instant grit to. Also, there is a grit to micron chart, and conversions for mesh. Web king & prince reign over the billboard japan hot 100 with “halfmoon,” blasting in at no. E ach abrasive has a listed hardness value, surface profile, surface removal ability, and. Web abrasive blasting media vary dramatically in particle size, hardness, shape, and other properties. Sandblasting media is. Web king & prince reign over the billboard japan hot 100 with “halfmoon,” blasting in at no. Web material mesh size shape density lbs/ft3 mohs friability initial cost # of cycles per use cost source typical apps sil. Surface preparation vs surface cleaning; The following chart will explain the characteristics of various media types. Web guide to abrasive blasting media. Web in this guide, we spell out which common abrasive blast media work best for which materials, from glass beads to walnut shells. While the common term may be “sandblasting media” or “sand blast. Web picking grit size for sandblasting; Aluminum oxide, steel shot as. 1 on the chart released may 29. With diy auto restorers in mind, we’ll. January 15, 2020 / admin / no comments. Lower numbers mean larger, while higher numbers mean the particles are more fine. Web guide to abrasive blasting media. Surface preparation vs surface cleaning; Covers glass bead, aluminum oxide, silicon carbide sand & walnut shell. Web material mesh size shape density lbs/ft3 mohs friability initial cost # of cycles per use cost source typical apps sil. Learn about the differences and applications of various blasting media, such as aluminum oxide, glass beads, silicon carbide, plastic, pumice, steel shot and more… The following chart will explain the characteristics of various media types. Web the below charts show a few types of abrasive used in dry media blasting. Web reference chart to which blasting media is best for restoration & stripping what material.

Blast Media Chart Grainger Industrial Supply

Choosing The Right Blast Media For Abrasive Blasting

7 Things You Should Be Doing When Sandblasting Midvale Industries

Sandblast Media Chart livewire.thewire.in

Choosing the Right Blast Media for Abrasive Blasting

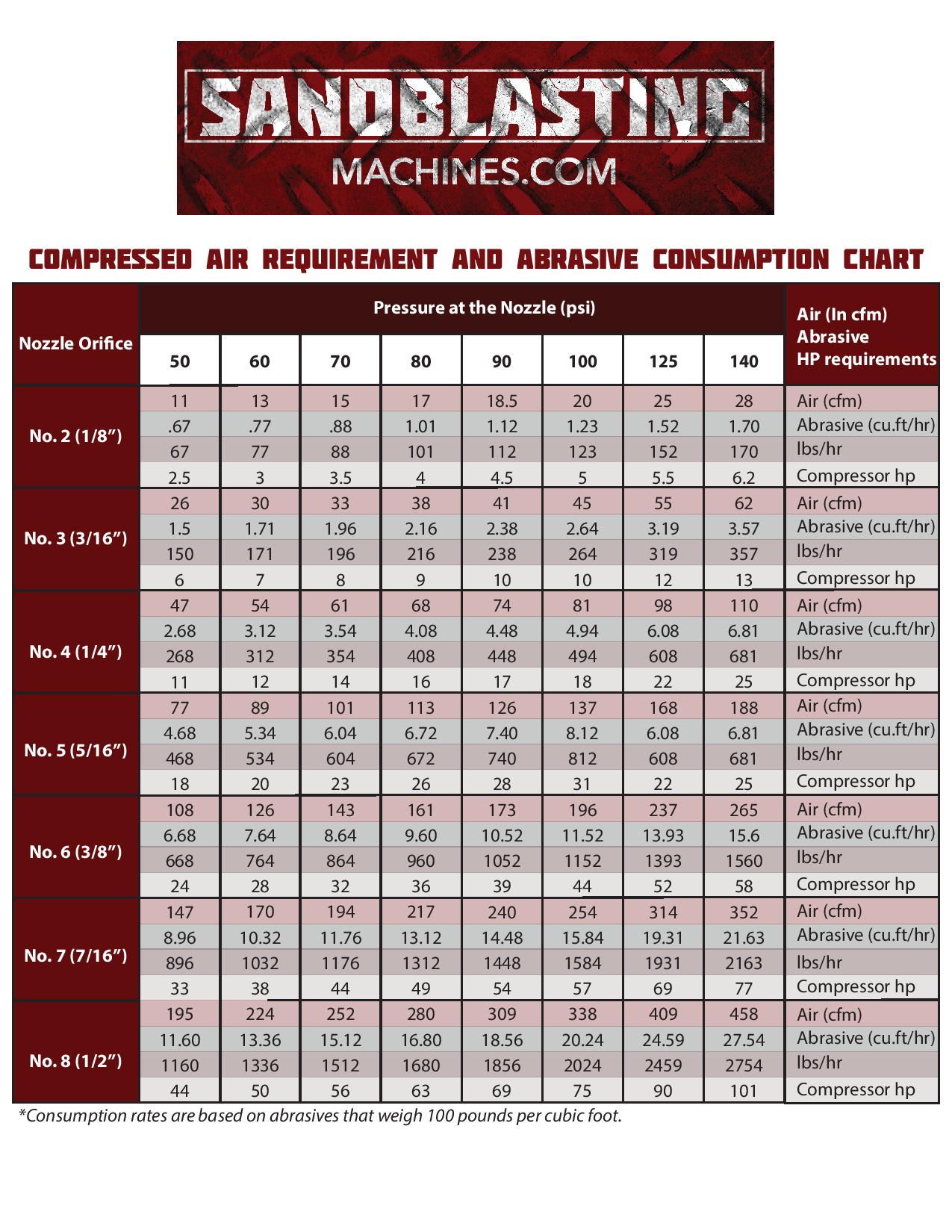

Understanding Sandblasting Compressor Size Requirements Sandblasting

Glass Beads for SandblastingLangfang Olan Glass Beads Co., Ltd Olan

Sand Blast Media Chart A Visual Reference of Charts Chart Master

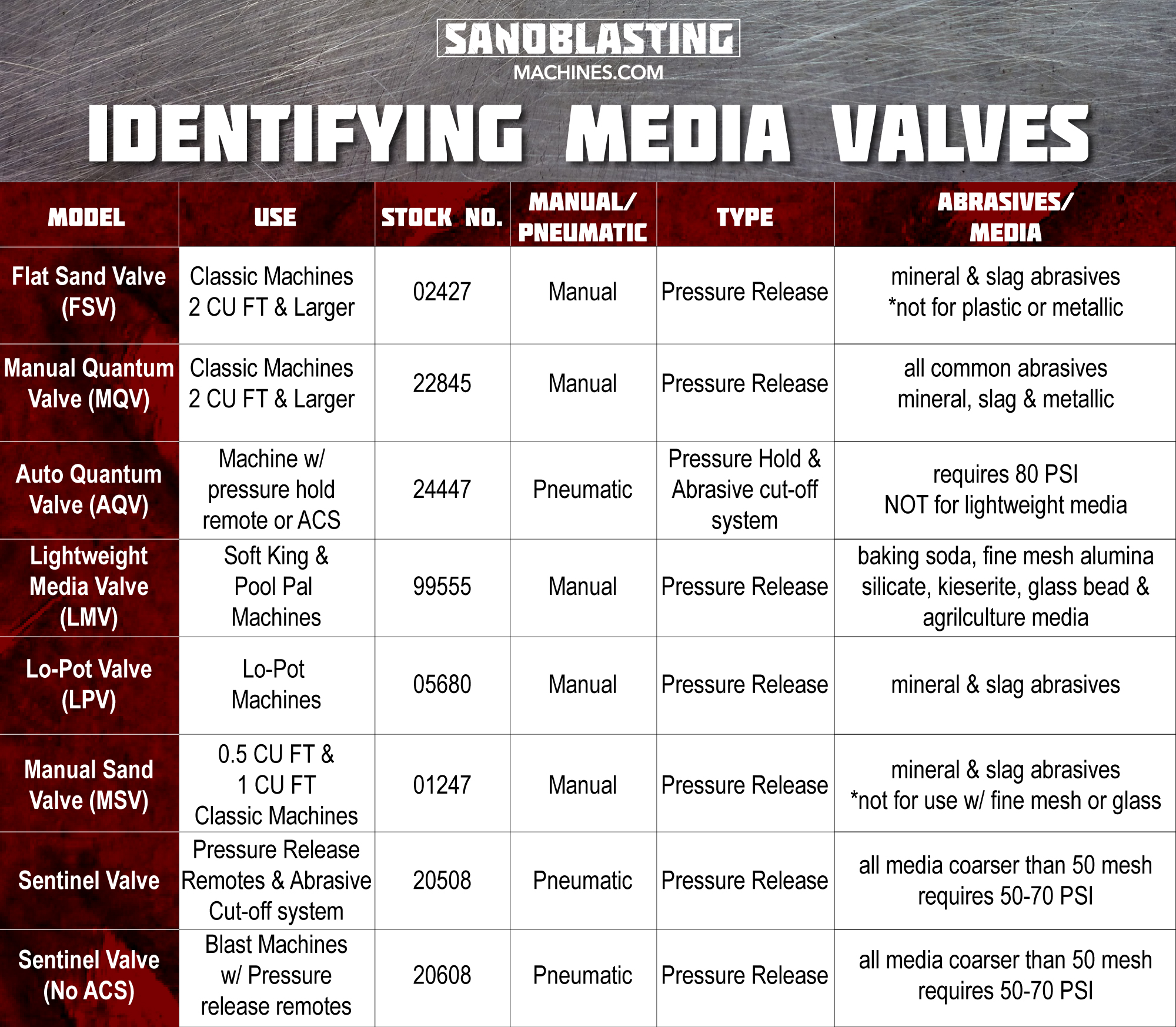

Types of Media Valves for Sandblasting Sandblasting Machines

How to Sandblast Sandblast, Sandblasting, Sodablast, Sodablasting

Web Media Blasting (Also Called Sandblasting Or Abrasive Blasting) Has Many Uses, From Removing A Layer Of Paint To Deodorizing Molded Wood Beams To Removing.

Sandblasting Media Is The Material Used In The Sandblasting Process To Remove Surface Contaminants, Smooth Out Rough Surfaces, Or Etch Designs.

Web This Media Is Ideal For Stripping Coatings And Paint From Substrates, Including Aluminum And Other Delicate Metals, Composites And Plastics.

Web Abrasive Blasting Media Vary Dramatically In Particle Size, Hardness, Shape, And Other Properties.

Related Post: