Sandvik Grade Chart

Sandvik Grade Chart - Web the list below contains the most compatible modern grades by sandvik. Our powercarbide consists of the grades dp55, dp65, gc80, sh70,. The wide range of carbide threading grades from sandvik coromant offers high productivity for many materials and applications. Web our existing milling grades, we have created a strong and reliable grade chain for titanium milling. Uncoated carbide grade combines good abrasive wear resistance and toughness in low to moderate speeds and high feeds. Use the information below to find the right grade for your. Web cvd grade comparison chart iso wecotool sandvik kennametal secotool iscar taegutec walter tungaloy kyocera korloy sumitomo mitsubishi zcc.ct k10 gc3210 gc3215 kck05. Web grade comparison table cemented carbide note 1) the above table is selected from a publication. Web milling inserts and grades. Choose workpiece material (iso p/steel, iso m/stainless steel, iso k/cast iron, iso n/ aluminum alloys,. Choose workpiece material (iso p/steel, iso m/stainless steel, iso k/cast iron, iso n/ aluminum alloys,. A score (up to 100%) shows the compatibliny of the listed grade with gc1025. Web we are now very proud to gather our most powerful carbide grades under one name: Regardless of component size, material or design, the carbide insert grade you use can make. For long tool life in grooving applications in steel and cast iron. Use the information below to find the right grade for your. Excellent for finishing to light roughing. Our powercarbide consists of the grades dp55, dp65, gc80, sh70,. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. Web grade comparison table cemented carbide note 1) the above table is selected from a publication. Regardless of component size, material or design, the insert grade you use can make all the difference in your manufacturing productivity. S30t use insert grade s30t for best tool life and largest cutting data. Web our existing milling grades, we have created a strong. Web we are now very proud to gather our most powerful carbide grades under one name: Web cvd grade comparison chart iso wecotool sandvik kennametal secotool iscar taegutec walter tungaloy kyocera korloy sumitomo mitsubishi zcc.ct k10 gc3210 gc3215 kck05. Web welcome to the cutting speed calculator. Web 452 rows get full information on any carbide grade. Regardless of component size,. Excellent for finishing to light roughing. Web we divide the grades into several grade statuses: Select the most suitable tool. Uncoated carbide grade combines good abrasive wear resistance and toughness in low to moderate speeds and high feeds. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Use the information below to find the right grade for your. Uncoated carbide grade combines good abrasive wear resistance and toughness in low to moderate speeds and high feeds. It defines smc's steel marking system and the standards that steel. Our powercarbide consists of the grades dp55, dp65, gc80, sh70,. Choose workpiece material (iso p/steel, iso m/stainless steel, iso k/cast. Web we are now very proud to gather our most powerful carbide grades under one name: Use the information below to find the right grade for your. Bold type = standard horizon grades and. Our powercarbide consists of the grades dp55, dp65, gc80, sh70,. Whether you are parting off small. Web this document provides specifications for steel materials used by sandvik mining and construction (smc). Use the information below to find the right grade for your. Bold type = standard horizon grades and. Web milling inserts and grades. Select the most suitable tool. It defines smc's steel marking system and the standards that steel. Web welcome to the cutting speed calculator. Excellent for finishing to light roughing. S30t use insert grade s30t for best tool life and largest cutting data. Select the most suitable tool. Whether you are parting off small. Web milling inserts and grades. It defines smc's steel marking system and the standards that steel. Web 452 rows get full information on any carbide grade. A score (up to 100%) shows the compatibliny of the listed grade with gc1025. Web sandvik coromant grade and geometry selection guide. Select the most suitable tool. Web our existing milling grades, we have created a strong and reliable grade chain for titanium milling. Excellent for finishing to light roughing. Uncoated carbide grade combines good abrasive wear resistance and toughness in low to moderate speeds and high feeds. Regardless of component size, material or design, the insert grade you use can make all the difference in your manufacturing productivity. Bold type = standard horizon grades and. Web 452 rows get full information on any carbide grade. Web grade comparison table cemented carbide note 1) the above table is selected from a publication. For long tool life in grooving applications in steel and cast iron. Web we divide the grades into several grade statuses: Web the list below contains the most compatible modern grades by sandvik. A score (up to 100%) shows the compatibliny of the listed grade with gc1025. The wide range of carbide threading grades from sandvik coromant offers high productivity for many materials and applications. These are approximate grade conversions. S30t use insert grade s30t for best tool life and largest cutting data.

Sandvik Introduces New Insert Grade

Sandvik Coromant GC4415 and GC4425 grades suitable for steel turning

Sandvik Insert Grade Chart My XXX Hot Girl

Sandvik Coromant grades

Sandvik Carbide Insert Grade Chart

Sandvik Coromant grades

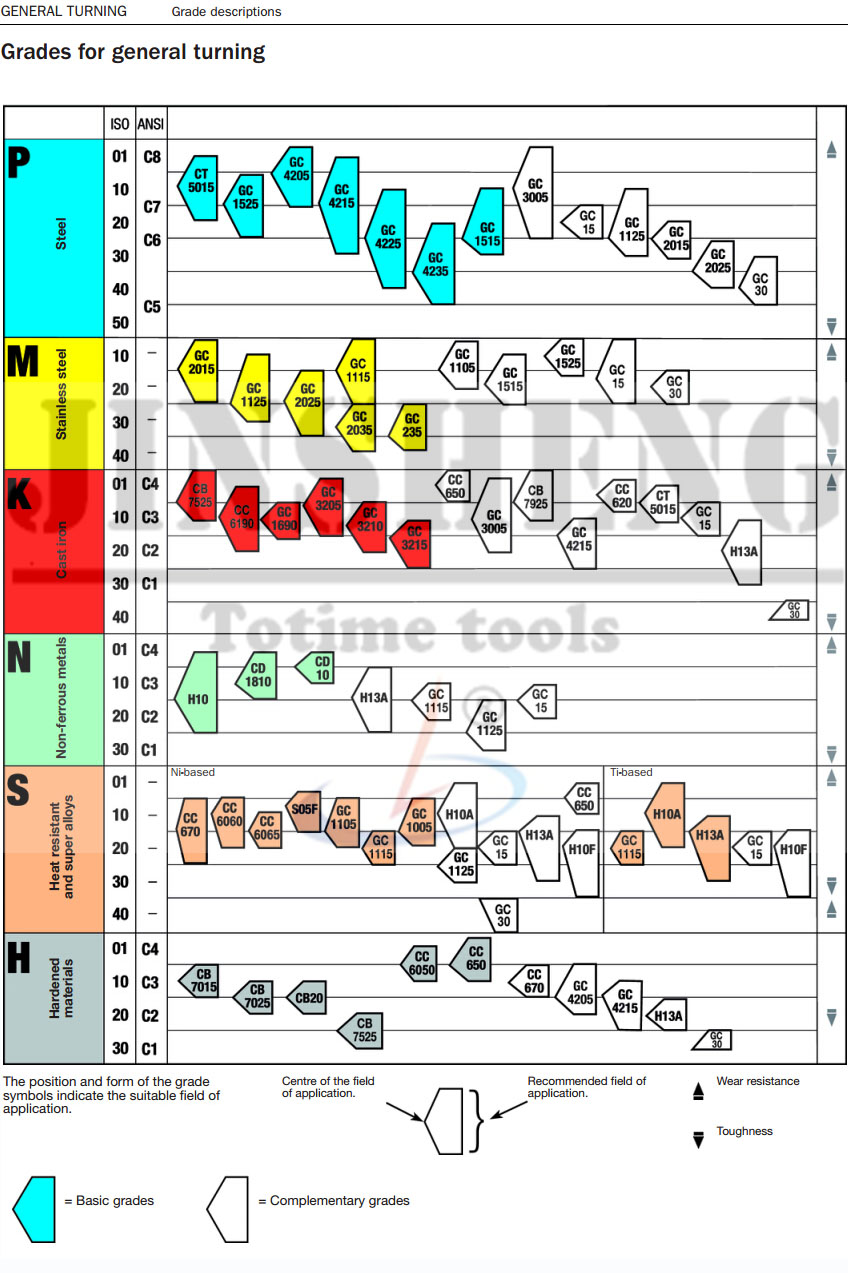

SANDVIK GRADES DESCRIPTION

Sandvik Grades

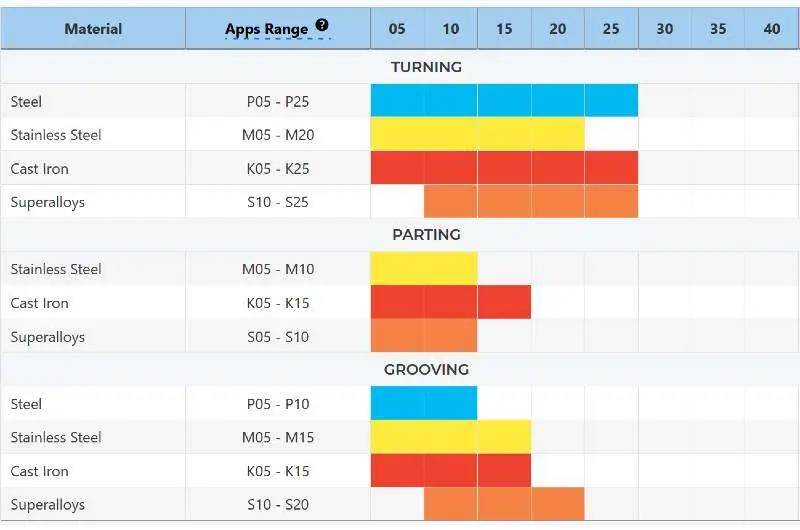

Sandvik Coromant Spectrum turning insert grades

Sandvik Tungsten Carbide Grade Chart Best Picture Of Chart

Specifying Appropriate Cutting Speed And Feed For Your Application Was Never So Easy.

Regardless Of Component Size, Material Or Design, The Carbide Insert Grade You Use Can Make All The Difference In Your Manufacturing Productivity.

Use The Information Below To Find The Right Grade For Your.

Including Cutting Speeds, Compatible Grades, Application Range, And More.

Related Post: