Screen Printing Mesh Count Chart

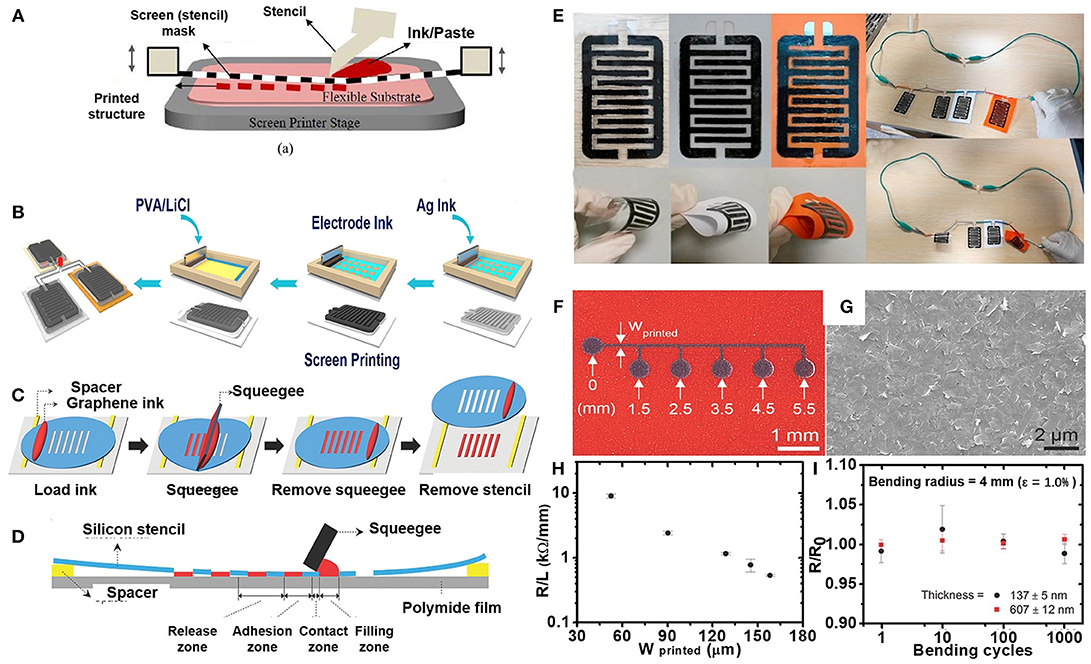

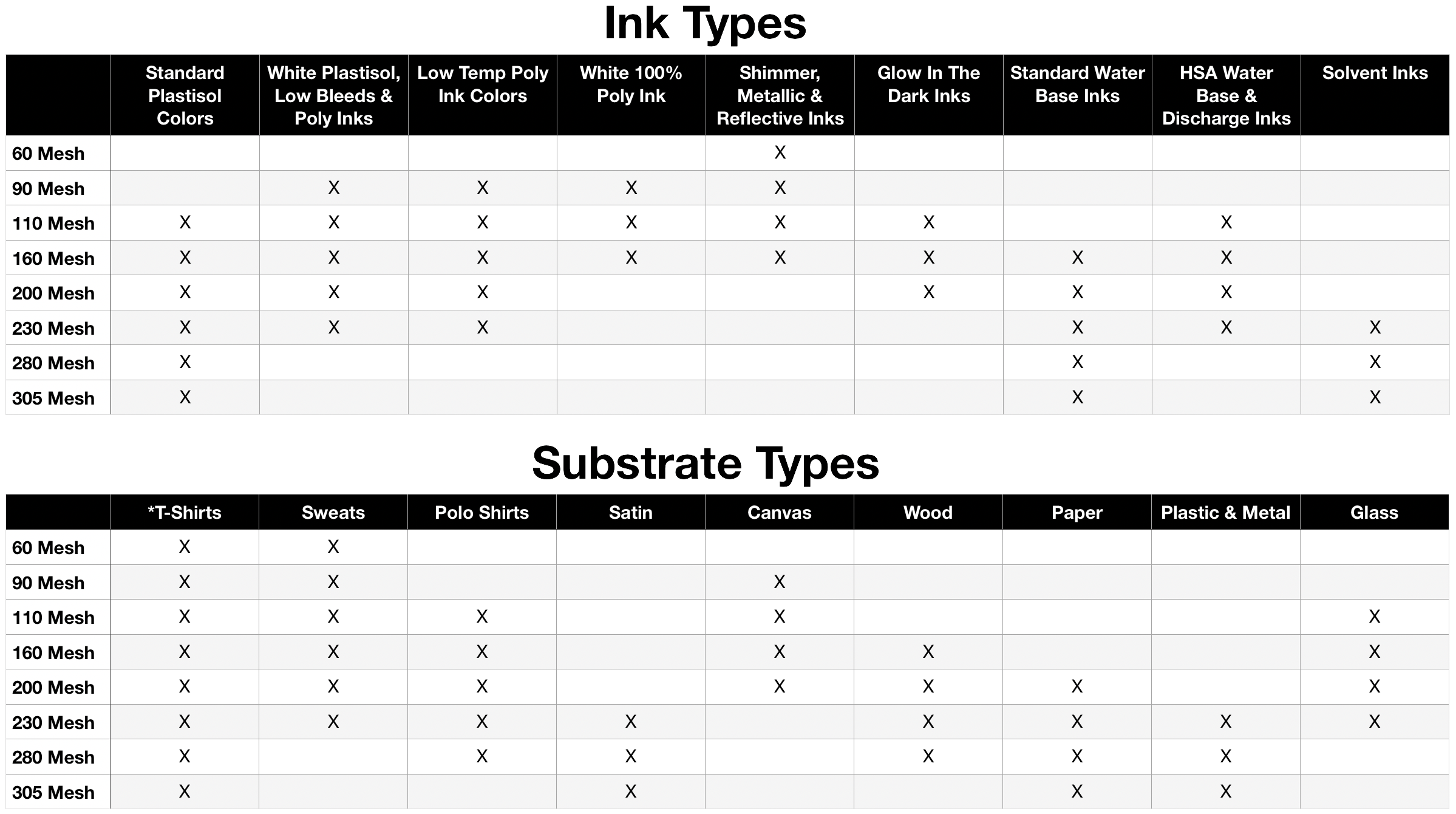

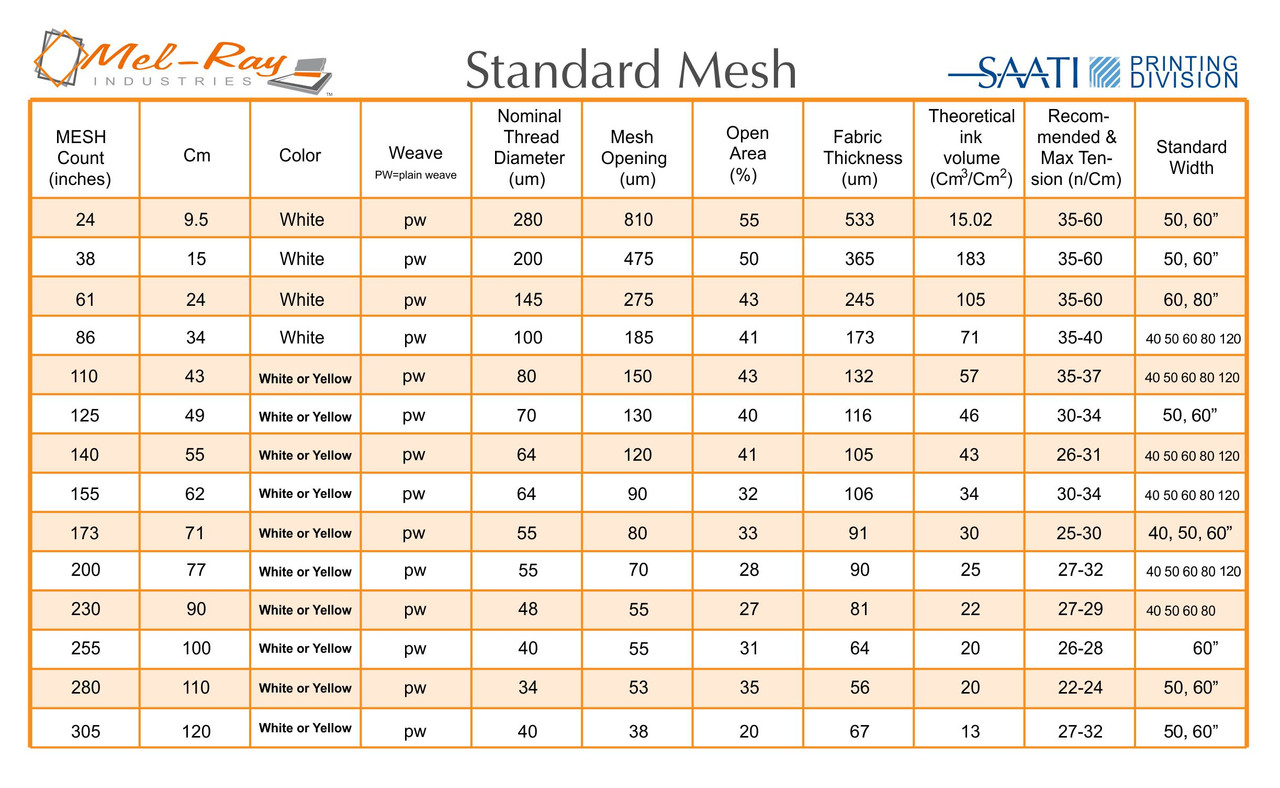

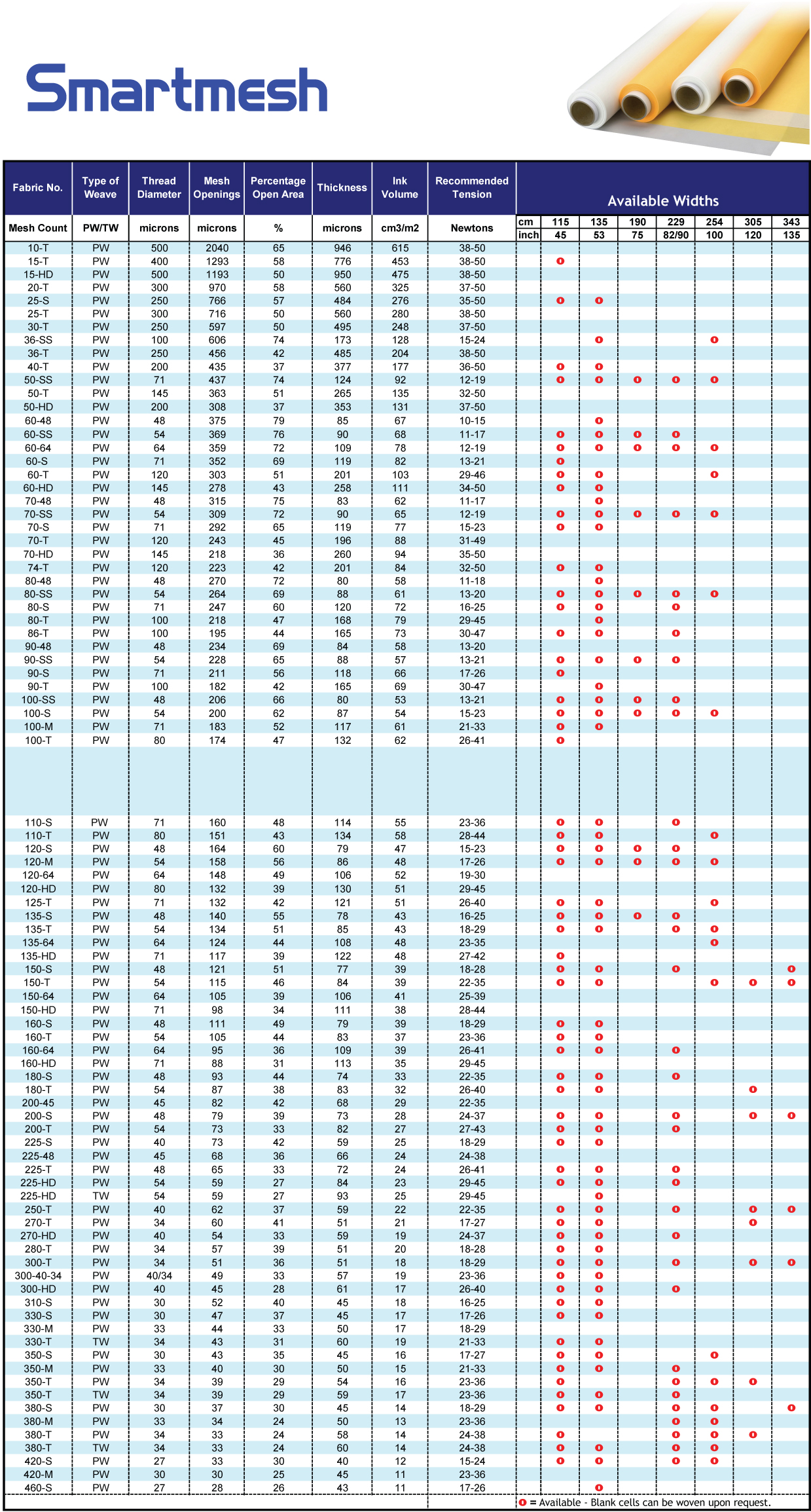

Screen Printing Mesh Count Chart - This is the nearest approximation of the calculated count (120 threads/cm x 2.54 cm/in. 30 to 61 mesh and 80 to 86 mesh. Supplies | equipment | classes. Used for specialist inks such as glitter or flakes (this allows the larger particles to be deposited on the substrate) most suited to paper printing, does not always give the best result on fabric. To determine the proper mesh to use with a particular dot, we multiply by 4.5. Download our free artwork cheatsheet to find out your mesh count and read on for a quick overview. The mesh count refers to the number of threads per inch contained in the mesh. Even when the screen opening has only 1.5 times the mesh pitch, ink with high printing performance makes quality printing possible. Web mesh count in screen printing refers to the number of polyester threads crossing each other per square inch on a screen; For example, let’s say we have artwork with 35 lpi (lines per inch) dots: This artwork cheatsheet covers 5 different types of image;. Web >covers specifications for mesh counts from 15t to 460s. Web a 156 mesh has 156 threads crossing every square inch, while a 320 mesh count screen has 320 threads of mesh intersecting in a single square inch. >find out recommended tensions by mesh count, as well as: This way, you’ll. Web uk 32t / us 80. The mesh count refers to the number of threads per inch contained in the mesh. Regardless of the screening material, the mesh count depends on the level of detail of the design. Higher mesh screens, 200 mesh and above, are most often used for finer detail images and thinner inks. Here’s a guide to. Not recommended for four colour process. Web the most standard mesh counts in screen printing are 110 and 156. Dot size x 4.5 = mesh count. Web this comprehensive guide dives deep into understanding screen printing mesh, exploring mesh count, its influence on your project, and the factors to consider when choosing the perfect mesh for your screen printing needs.. This artwork cheatsheet covers 5 different types of image;. Web the most standard mesh counts in screen printing are 110 and 156. For example, let’s say we have artwork with 35 lpi (lines per inch) dots: Web let’s start with the halftone dot. 30 to 61 mesh and 80 to 86 mesh. Web mesh count is simply the number and space between adjacent threads in your screen. A very fine mesh count used for highly detailed prints and fine halftones. This way, you’ll lay down enough ink to get a great print, but not so much ink to smash out the design. Web mesh selection for screen printing. To determine the proper. 30 to 61 mesh and 80 to 86 mesh. Web generally, mesh counts ranging from 25 mesh to 305 mesh are ideal when screen printing. The mesh count refers to the number of threads per inch contained in the mesh. This information provides invaluable guidance on selecting the most suitable mesh count for every individual print job. This means a. Web let’s start with the halftone dot. Web >covers specifications for mesh counts from 15t to 460s. The higher mesh count helps to keep the thinner inks from flooding onto your substrate. Regardless of the screening material, the mesh count depends on the level of detail of the design. 110 mesh lays a fairly thick layer of ink down. While keeping a close eye on chart recommendations is a good idea, we also recommend experimenting with similar mesh sizes to find which count works best. Even when the screen opening has only 1.5 times the mesh pitch, ink with high printing performance makes quality printing possible. A very fine mesh count used for highly detailed prints and fine halftones.. Used for specialist inks such as glitter or flakes (this allows the larger particles to be deposited on the substrate) most suited to paper printing, does not always give the best result on fabric. The higher the mesh count, the finer the holes and the finer the detail. Screens on the lower end of the mesh count spectrum put down. To determine the proper mesh to use with a particular dot, we multiply by 4.5. Tune in for free print advice at norcal screen print supply. Good for high detailed designs and large halftones. Mesh openings determine the maximum particle sizes of ink that can flow through the screen. Used for specialist inks such as glitter or flakes (this allows. How do printers choose the right mesh count for a job? Web the screen printing mesh count chart is a crucial reference for those in the screen printing industry, aimed at delivering optimal print outcomes. Web mesh selection for screen printing. For example, let’s say we have artwork with 35 lpi (lines per inch) dots: Web in general, there is no better way of knowing what mesh to use for screen printing than consulting a screen printing mesh size chart. While keeping a close eye on chart recommendations is a good idea, we also recommend experimenting with similar mesh sizes to find which count works best. It will give you an idea of what mesh count to use for each printing job. Not recommended for four colour process. This artwork cheatsheet covers 5 different types of image;. Even when the screen opening has only 1.5 times the mesh pitch, ink with high printing performance makes quality printing possible. This way, you’ll lay down enough ink to get a great print, but not so much ink to smash out the design. A very fine mesh count used for highly detailed prints and fine halftones. Regardless of the screening material, the mesh count depends on the level of detail of the design. Dot size x 4.5 = mesh count. 30 to 61 mesh and 80 to 86 mesh. Supplies | equipment | classes.

Screen Printing Mesh Count

Screen Printing Mesh Count

Smartmesh Polyester Mesh Murakami

Understanding Screen Printing Mesh Counts The Strategist and

A great chart for screen mesh count selection! Get all of these and

Metric Conversion Table for Screen Mesh High Quality Inks, Screen

Choosing Your Screen Mesh Count

Screen Printing Mesh Variety of Mesh Counts & Widths

Screen Printing Mesh Count Chart

Screen Mesh Sizes Chart

With Higher Counts Providing Finer Detail And Lower Counts Accommodating Thicker Inks Or Rougher Surfaces.

110 Mesh Lays A Fairly Thick Layer Of Ink Down.

Here’s A Guide To The Most Popular Mesh Counts And How To Use Them.

Used For Specialist Inks Such As Glitter Or Flakes (This Allows The Larger Particles To Be Deposited On The Substrate) Most Suited To Paper Printing, Does Not Always Give The Best Result On Fabric.

Related Post: