Siser Htv Temperature Chart

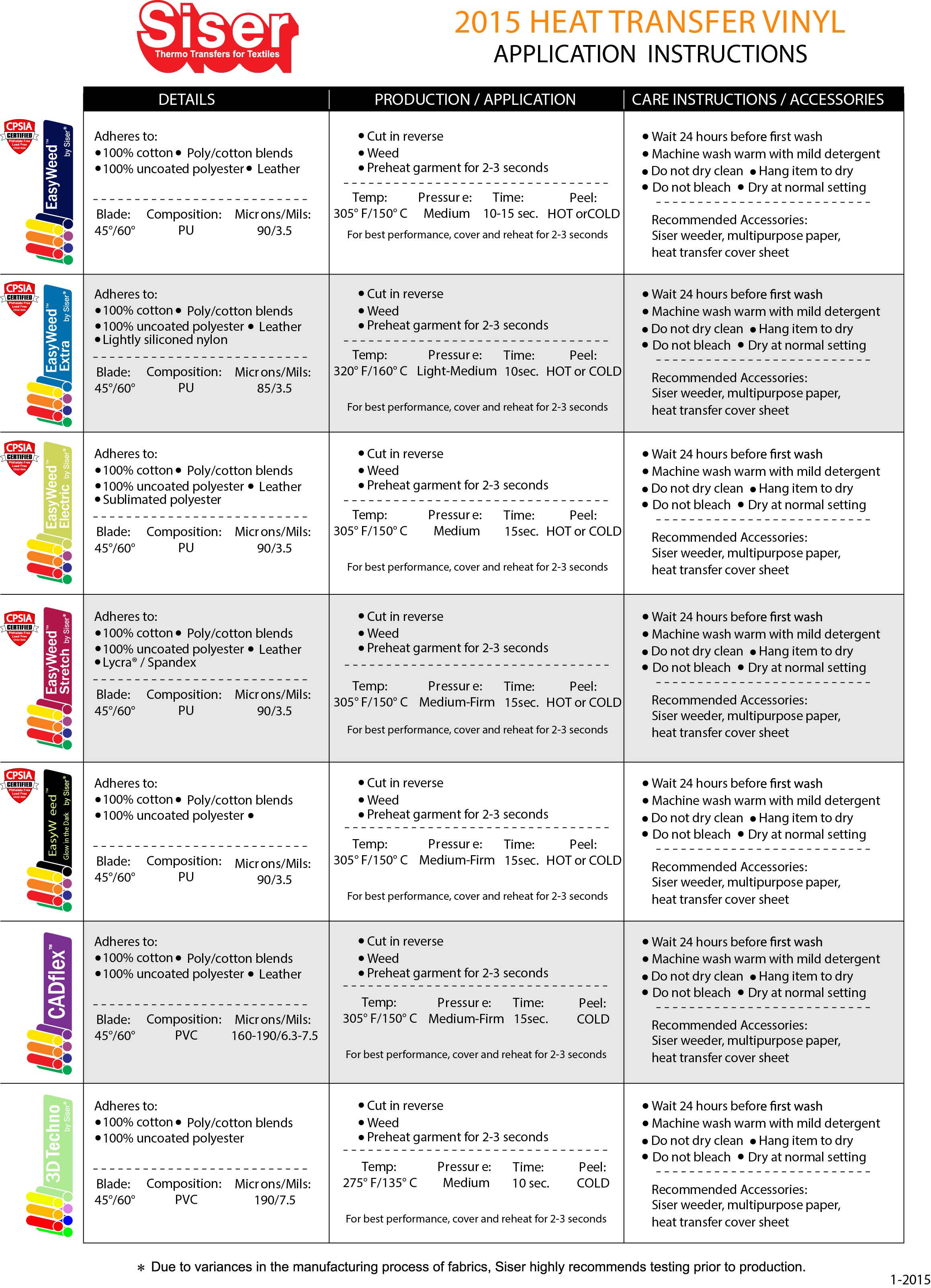

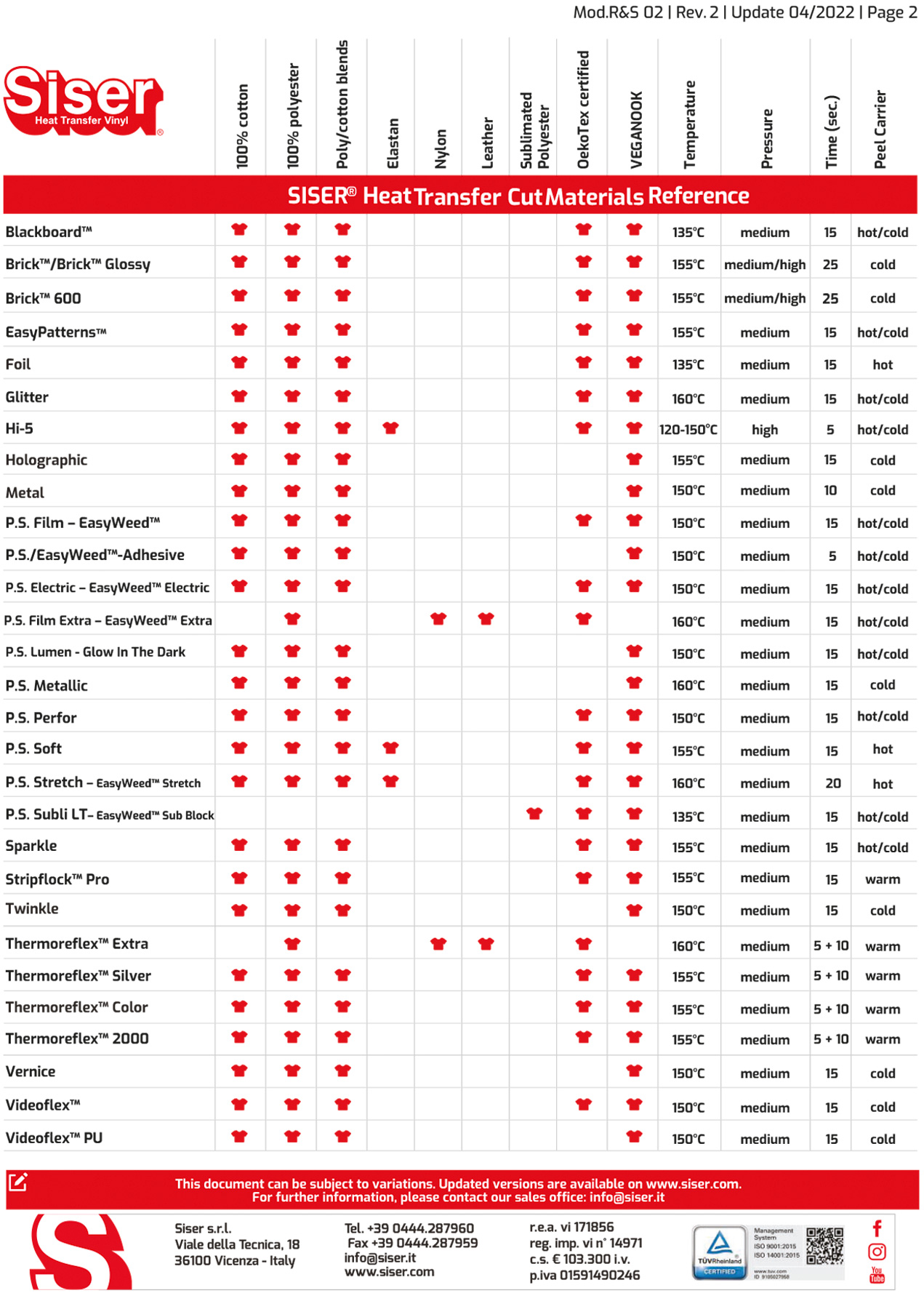

Siser Htv Temperature Chart - Web heat up to 320℉ /160℃ within 4 mins, saving 2minutes than common type. Our heat transfer vinyl (htv) materials are a polyurethane (pu) material that comes on a clear carrier sheet. Due to variances in the manufacturing process of fabrics, siser highly recommends testing prior to production. This results in a smooth, colorful finish. Suitable for cotton, polyesters, blends, lycra/spandex. Web htv is available in hundreds of colors and finishes like glitter, holographic, blackboard®, and more. Web cricut offers a guide to each setting and their temperature range, but you’ll still need to tack on that extra 30°f for best results with siser htv, so you’ll likely end up using the middle or highest setting for most projects. First things first, what is htv? Always perform a test cut temper pressure: Web using a standard heat press, siser htv application temperatures range from 250 o f to 320 o f, and typically use medium pressure. 100% cotton 100% polyester poly/cotton blends elastan nylon leather sublimated polyester oekotex certified veganook temperature pressure time (sec.) peel carrier not all garments are created equal. Thermal transfer materials, and heat transfer paper. Web siser ® heat transfer. Web cricut offers a guide to each setting and their temperature range, but you’ll still need to tack on that extra 30°f. Web using a standard heat press, siser htv application temperatures range from 250 o f to 320 o f, and typically use medium pressure. Web application instructions (heat press): How to set temperature time pressure for heat press machine? In this blog, we will provide a complete guide to how to use heat transfer vinyl (htv) successfully. Suitable for cotton,. Web producer of screen printing supplies. The cricut heat guide no longer provides time/temp values when using a towel rather than a cricut pressing mat. Web free printable siser heat transfer vinyl quick guide. First things first, what is htv? We do not want your craft going wrong! Please test for compatibility on your garment before committing to production. Web application instructions (heat press): Due to variances in the manufacturing process of fabrics, siser highly recommends testing prior to production. Like this paper flower corsage with htv decorated ribbon? Web producer of screen printing supplies. Upt to 4 fast modes, 2 custom modes and an auto mode for your creativities. Web htv is available in hundreds of colors and finishes like glitter, holographic, blackboard®, and more. Due to variances in the manufacturing process of fabrics, siser highly recommends testing prior to production. Suitable for cotton, polyesters, blends, lycra/spandex. The cricut heat guide no longer provides. This product has been independently lab tested and is phthalate & lead compliant and is safe for application on children’s products. Web using a standard heat press, siser htv application temperatures range from 250 o f to 320 o f, and typically use medium pressure. In this blog, we will provide a complete guide to how to use heat transfer. Due to variances in the manufacturing process of fabrics, siser highly recommends testing prior to production. Web producer of screen printing supplies. Web using a standard heat press, siser htv application temperatures range from 250 o f to 320 o f, and typically use medium pressure. Almost all materials require pressing with firm pressure, with few exceptions. Web why siser. Siser htv products can be used with a home iron. We do not want your craft going wrong! Posted by hollie on 13th feb 2016. Set temperature between “cotton” and “linen” 2. Please test for compatibility on your garment before committing to production. Web please test for compatibility on your garment, before committing to production because not all garments are created equal. Posted by hollie on 13th feb 2016. Set temperature between “cotton” and “linen” ** wait 15 seconds before peeling cover sheet. Web cricut offers a guide to each setting and their temperature range, but you’ll still need to tack on that. How many times were you cutting and forget to reverse? Cpsia certified means that the material has been independently tested and is free of lead and phthalates and is safe for application on children’s products. First things first, what is htv? How to set temperature time pressure for heat press machine? Set temperature between “cotton” and “linen” ** wait 15. This results in a smooth, colorful finish. Web siser® easyweeder®, parchment or multipurpose paper, or heat transfer cover sheet. How to set temperature time pressure for heat press machine? Web siser® heat transfer vinyl reference. The cricut heat guide no longer provides time/temp values when using a towel rather than a cricut pressing mat. Web application instructions (heat press): 305 o f is the most common press temp for easyweed and other standard siser htv types. Cpsia certified means that the material has been independently tested and is free of lead and phthalates and is safe for application on children’s products. Web why siser and what is htv? First things first, what is htv? We have all done it! Set temperature between “cotton” and “linen” ** wait 15 seconds before peeling cover sheet. Suitable for cotton, polyesters, blends, 100% nylon. All siser htv products are suitable for cotton, polyesters, blends. * all siser htv products can be used with a home iron. Posted by hollie on 13th feb 2016.

Free Printable Siser Heat Transfer Vinyl Quick Guide vrogue.co

Editable Siser Stetch Color Chart Htv Color Chart For Siser Stretch Htv

Cheat Sheet Printable Heat Press Temperature Guide

Heat Press Temperature Chart For Siser HTV Snip To It!, 51 OFF

How to use heat transfer vinylhand holding tutorial Heat transfer

free printable siser heat transfer vinyl quick guide my vinyl direct

heat transfer vinyl htv heat settings from icraft vinyl com icraftvinyl

FREE PRINTABLE Siser Heat Transfer Vinyl Quick Guide My Vinyl Direct

Siser Heat Transfer Vinyl

Fluorescent EasyWeed 12"X24" Heat Transfer Sheet Expressions Vinyl

(Print & Cut) Siser Print And Cut Products Are Not Compatible With Inkjet Or Laser Printers.

Web Every Heat Transfer Vinyl Is A Little Different In Regards To Pressing Time, Temperature, Pressure, And Peel!

Web Improper Use—Including Pressure, Temperature, And Time Settings—Can Cause Your Vinyl To Burn Or Not Stick.

Web Siser ® Heat Transfer.

Related Post: