Smaw Welding Electrode Chart

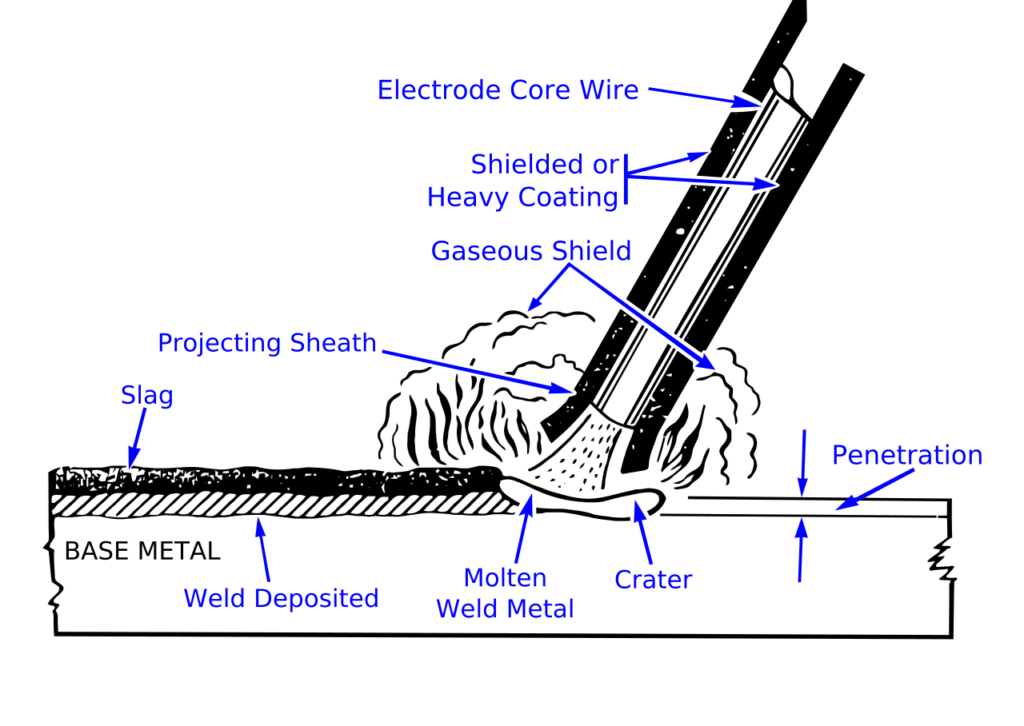

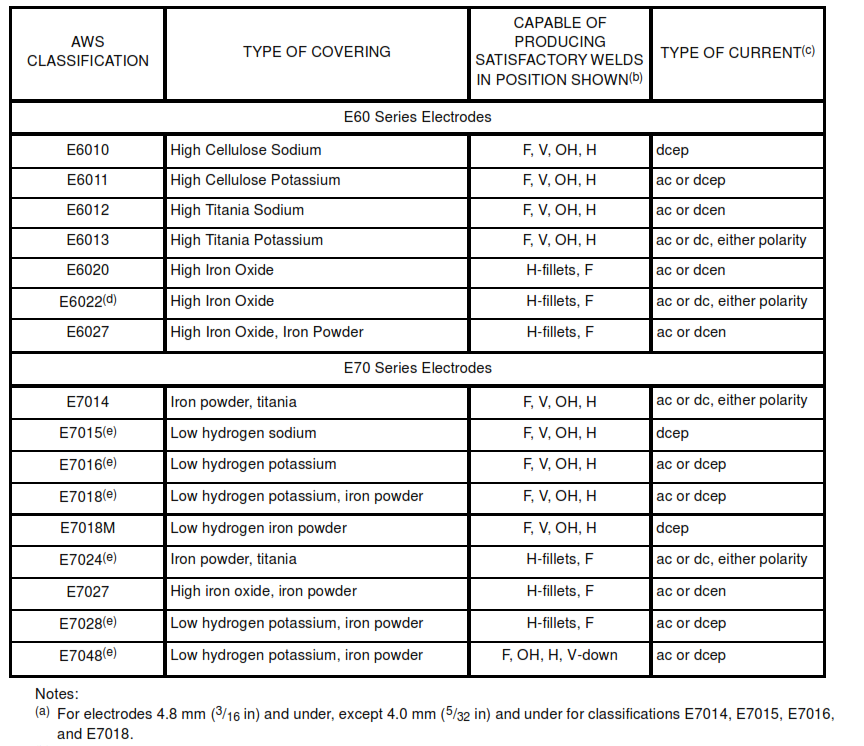

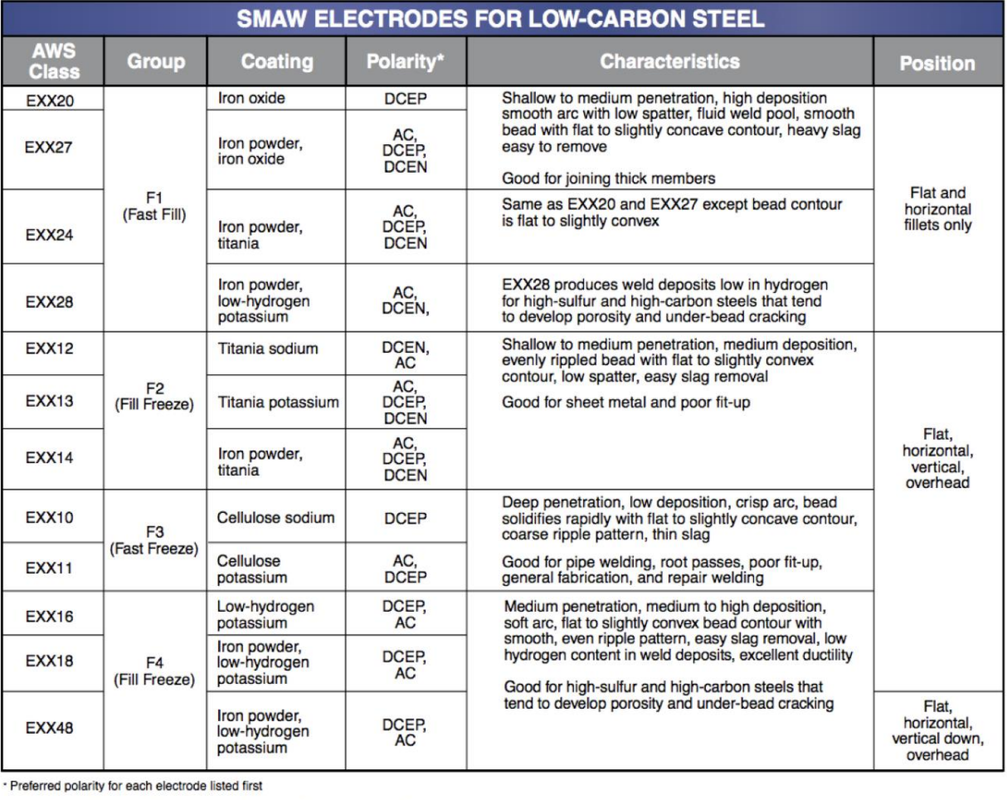

Smaw Welding Electrode Chart - Fuses the two parts together and establishes the depth of weld penetration. Web a welding electrode chart categorizes electrodes based on factors such as material, coating, current, and position. Wear body protection made from durable, flame−resistant material (leather, heavy. The electrode will melt following this action and will fuse with the base. Web smaw welding or stick welding electrodes types are classified based on the following factors: Welding electrode selection chart.pdf for most. Web in this welding rod chart, you will find over 220 stick electrodes classified according to the american welding society (aws) code. We will discuss these factors one by. The fillet size (l) is meant to represent the base and height of the triangle used in the. Web copper alloy electrodes.16 nickel alloy steel electrodes.17 proper care and handling of smaw electrodes.18 special precautions for low hydrogen. For smaw process, weaving shall be 3 times core dia. The pdf has 8 sections:. Web what is stick welding (smaw)? Web en iso 14172 covered electrodes for manual metal arc welding of nickel and nickel alloys. Web in this welding rod chart, you will find over 220 stick electrodes classified according to the american welding society (aws) code. Base metal or parent metal. Web a welding electrode chart categorizes electrodes based on factors such as material, coating, current, and position. Web smaw welding or stick welding electrodes types are classified based on the following factors: What are the most common stick rods for. The choice of electrode depends on the material being welded, the welding position, and the. Web en iso 14172 covered electrodes for manual metal arc welding of nickel and nickel alloys. The choice of electrode depends on the material being welded, the welding position, and the specific requirements of the. What to consider before selecting a stick welding rod type? Web smaw welding or stick welding electrodes types are classified based on the following factors:. Fuses the two parts together and establishes the depth of weld penetration. We will discuss these factors one by. Web smaw welding or stick welding electrodes types are classified based on the following factors: Web use this chart to find welding electrodes for welding duplex stainless steel, super duplex stainless steel, and welding duplex stainless steel to carbon steel,. The. Base metal or parent metal. Wear body protection made from durable, flame−resistant material (leather, heavy. Web shielded metal arc welding (smaw) electrodes are designated by “e” followed by four (or five) digits for example: Web welding electrodes classification for shielded metal arc welding (smaw) by american welding society (aws) is as follows. First weld bead of a multiple pass weld. Welding electrode selection chart.pdf for most. First weld bead of a multiple pass weld. Web you can these below welding electrode selection charts to guide you for welding electrode selection. Wear body protection made from durable, flame−resistant material (leather, heavy. The electrode will melt following this action and will fuse with the base. The electrode will melt following this action and will fuse with the base. Web en iso 14172 covered electrodes for manual metal arc welding of nickel and nickel alloys. Welding electrode selection chart.pdf for most. First weld bead of a multiple pass weld. What kinds of stick electrodes are there? Base metal or parent metal. What to consider before selecting a stick welding rod type? Welding electrode selection chart.pdf for most. What are the most common stick rods for. First weld bead of a multiple pass weld. What to consider before selecting a stick welding rod type? Fuses the two parts together and establishes the depth of weld penetration. Web welding electrodes classification for shielded metal arc welding (smaw) by american welding society (aws) is as follows. Stick welding electrode categories by flux composition; The pdf has 8 sections:. Web copper alloy electrodes.16 nickel alloy steel electrodes.17 proper care and handling of smaw electrodes.18 special precautions for low hydrogen. The chart below is meant for fillet welds. First weld bead of a multiple pass weld. Web you just need to quickly touch the base metal with an electrode and raise it slightly to create the arc. The pdf has. Stick welding electrode categories by flux composition; Web what is stick welding (smaw)? The electrode will melt following this action and will fuse with the base. For smaw process, weaving shall be 3 times core dia. Web stick welding (smaw) electrode amperage chart. What are the most common stick rods for. Web you can these below welding electrode selection charts to guide you for welding electrode selection. What kinds of stick electrodes are there? Web table of contents. I will explain the meaning of these. First weld bead of a multiple pass weld. The choice of electrode depends on the material being welded, the welding position, and the specific requirements of the. Web smaw welding or stick welding electrodes types are classified based on the following factors: Web how do i choose the right electrode for smaw welding? Web welding electrodes classification for shielded metal arc welding (smaw) by american welding society (aws) is as follows. The pdf has 8 sections:.

The Complete Guide of How to Stick Weld (SMAW) Kings of Welding

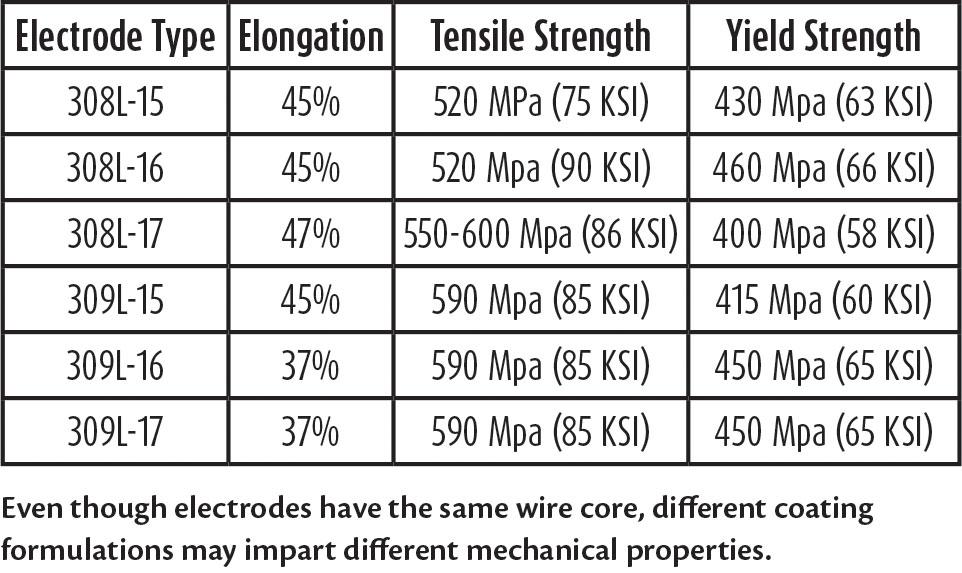

Mastering stainless SMAW electrodes

Selection and Use of Electrodes for SMAW of Low Carbon Steel PAKTECHPOINT

Welding electrodes Understanding the SMAW electrode symbols Welding

Welding electrodes Understanding the SMAW electrode symbols Welding

Selection and Use of Electrodes for SMAW of Low Carbon Steel PAKTECHPOINT

Welding Electrode Types Chart

Electrode Amperage Chart Baker's Gas & Welding Supplies, Inc.

SMAW Welding Class

Stick(SMAW) Welding Basics Welding electrodes, Welding

Welding Electrode Selection Chart.pdf For Most.

The Fillet Size (L) Is Meant To Represent The Base And Height Of The Triangle Used In The.

Base Metal Or Parent Metal.

Fuses The Two Parts Together And Establishes The Depth Of Weld Penetration.

Related Post: