Stick Welding Amps To Metal Thickness Chart

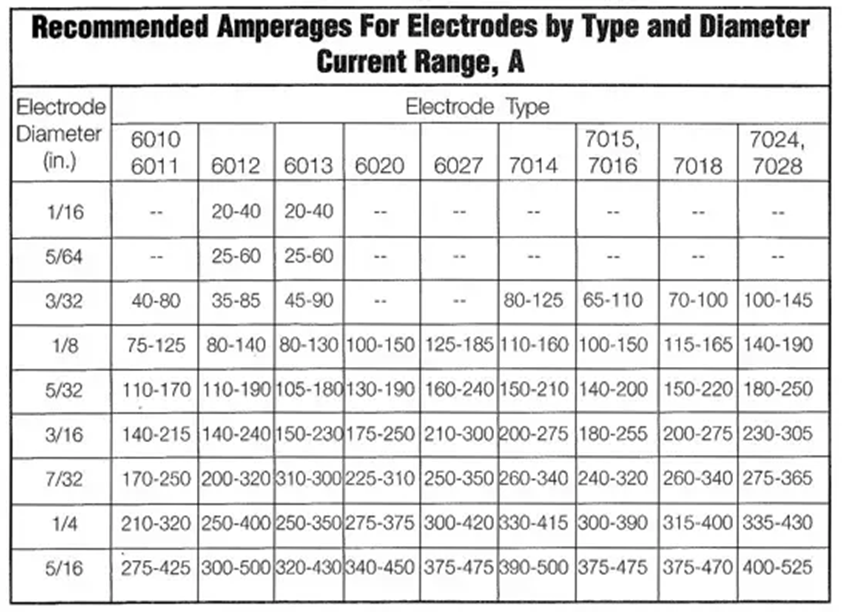

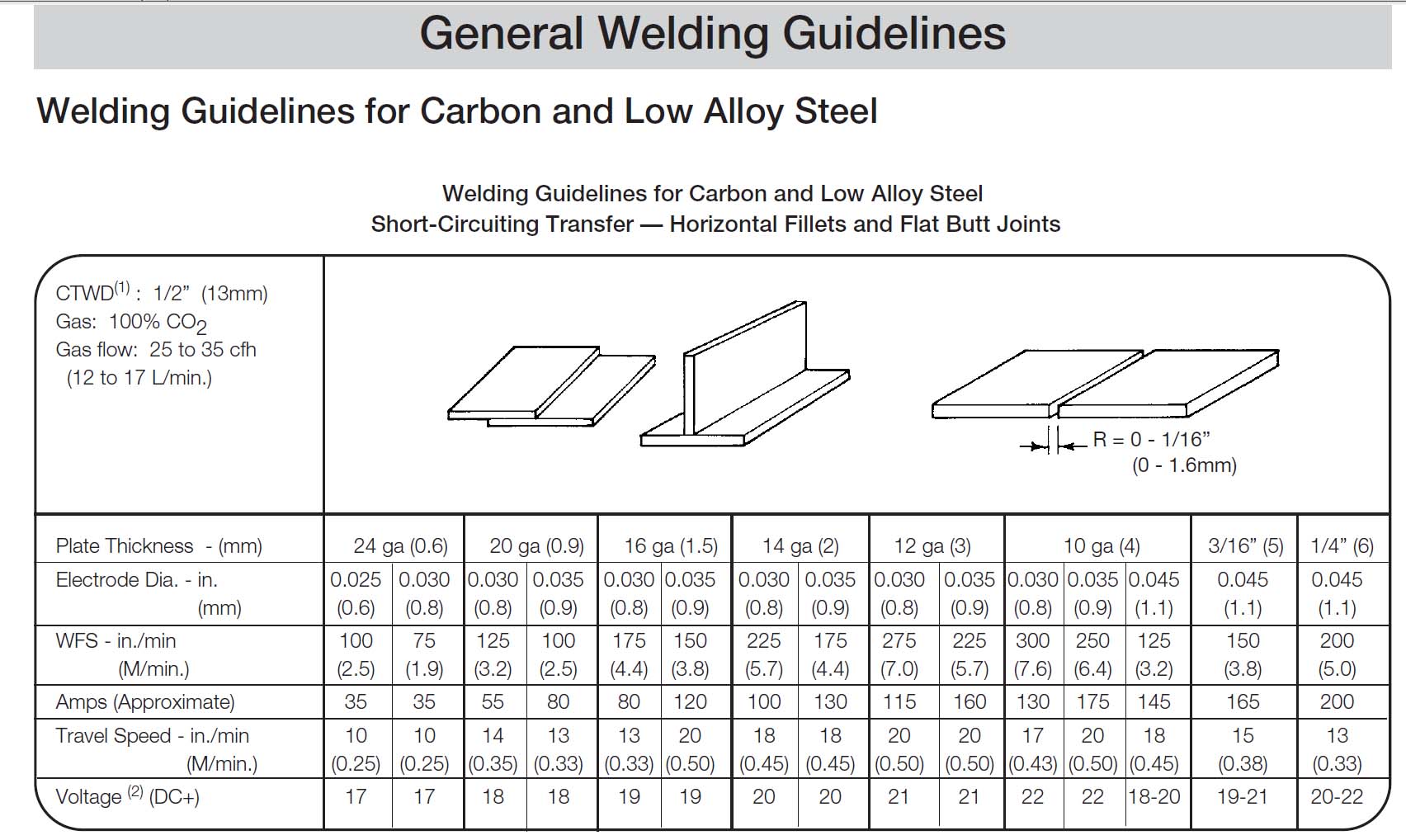

Stick Welding Amps To Metal Thickness Chart - Web stick welding amperage for different steel thicknesses. Web stick welding rod size charts are readily available online or in welding reference books. Find the type of metal and thickness of the material that you plan to weld on the chart and look at the recommended amperage level that corresponds to those. Tips for vertical stick welding. The tig calculator is intended as a print out reference for diy tig welders but is only intended as a starting point. This help determines what the various options are designed for and which ones should be used at different times. Web vertical stick welding amperage per metal thickness in inches and mm. Look for a stick welding amperage chart online or in your stick welder’s manufacturer’s instructions. What are the most common stick rods for home. Also, similar to other welding styles, tig welding relies on essential variables to determine what settings are appropriate for each application. Web stick welding amperage for different steel thicknesses. The number represents the diameter of the rod, while the letter indicates the type There might be variations with the settings depending on the manufacturer. Find the amperage for a type and thickness of metal on a welding chart. You will need to set the machines low enough not to burn through. You will need to set the machines low enough not to burn through base metal but still high enough to get an arc start. 6013 welding rods for mild steel. What is the best rod for vertical welding? Plus you'll get the most complete welding rod chart on the internet in pdf! The number represents the diameter of the rod,. Web here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: Find the type of metal and thickness of the material that you plan to weld on the chart and look at the recommended amperage level that corresponds to those. The welding amp calculator will then calculate the. This size of rod is commonly used for welding medium gauge metal and for. What are the most common stick rods for home. Plus you'll get the most complete welding rod chart on the internet in pdf! The adjustments to stick welding amperage to compensate for steel material thickness are similar to the processes necessary to compensate for material thickness. 3.1 thickness of the metal and electrode size. So, how many amps does it take to weld 3/8 steel? Web stick welding amperage for different steel thicknesses. You will need to set the machines low enough not to burn through base metal but still high enough to get an arc start. Can you stick weld vertically? What to consider before selecting a stick welding rod type? Web tig welding amp charts. So what are the other letters and numbers on the label? There might be variations with the settings depending on the manufacturer. Web often the answer comes from testing your best guess at power. The adjustments to stick welding amperage to compensate for steel material thickness are similar to the processes necessary to compensate for material thickness with a mig welder. Web what material are you welding? Web once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that. Web here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: This feature can help you compensate the power for the low amp start that you will need for thin mild steel. 6013 welding rods for mild steel. Web what are the welding rods? Web stick welding rod. Look for a stick welding amperage chart online or in your stick welder’s manufacturer’s instructions. You will need to set the machines low enough not to burn through base metal but still high enough to get an arc start. Like any other type of welding, it is critical to understand tig welding settings and requirements to create a sustainable and. 6013 welding rods for mild steel. Once you get the hang of tig welding you might find you prefer to weld at higher or lower amps depending on technique and travel speed. 1.1 how do welding rods differ? Find the amperage for a type and thickness of metal on a welding chart. What to consider before selecting a stick welding. Web once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that specific electrode. Consulting a reputable manufacturer’s website or a welding handbook can help you find a comprehensive stick welding rod size chart. Web what material are you welding? There might be variations with the settings depending on the manufacturer. Always follow electrode manufacturer’s guidelines. What are the most common stick rods for home. Also, similar to other welding styles, tig welding relies on essential variables to determine what settings are appropriate for each application. Web a general rule of thumb is you need 1 amp of power for every 0.001 inches of steel. So, how many amps does it take to weld 3/8 steel? Web stick welding amperage for different steel thicknesses. Can you stick weld vertically? Web firstly, input the necessary parameters such as material thickness, joint type, and electrode diameter. Browse suggested weld parameter settings for stick welding. Arc force (dig) for vertical welding. This size of rod is commonly used for welding medium gauge metal and for. Web tig welding amp charts.

Stick Amps Vs Rod size Vs metal thickness Welding rod chart, Welding

Stick Welding Amp Chart

ضبط الامبير للحام القواعد الذهبية فى اللحام القاعدة الرابعةWelding

stick welding chart

Tig Welding Amperage Chart

Welding Amps Metal Thickness Chart

MIG settings for welding different thickness mild steel

Welding

7018 1/8 Welding Rod Amperage Chart

What are a reasonable rods to use ? Welding Site

This Feature Can Help You Compensate The Power For The Low Amp Start That You Will Need For Thin Mild Steel.

How To Choose A Correct Welding Rod Size.

These Charts Provide Information On Recommended Rod Sizes Based On Material Thickness And Welding Amperage.

2.1 How Is Welding Rod Diameter Measured?

Related Post: