Threaded Insert Size Chart

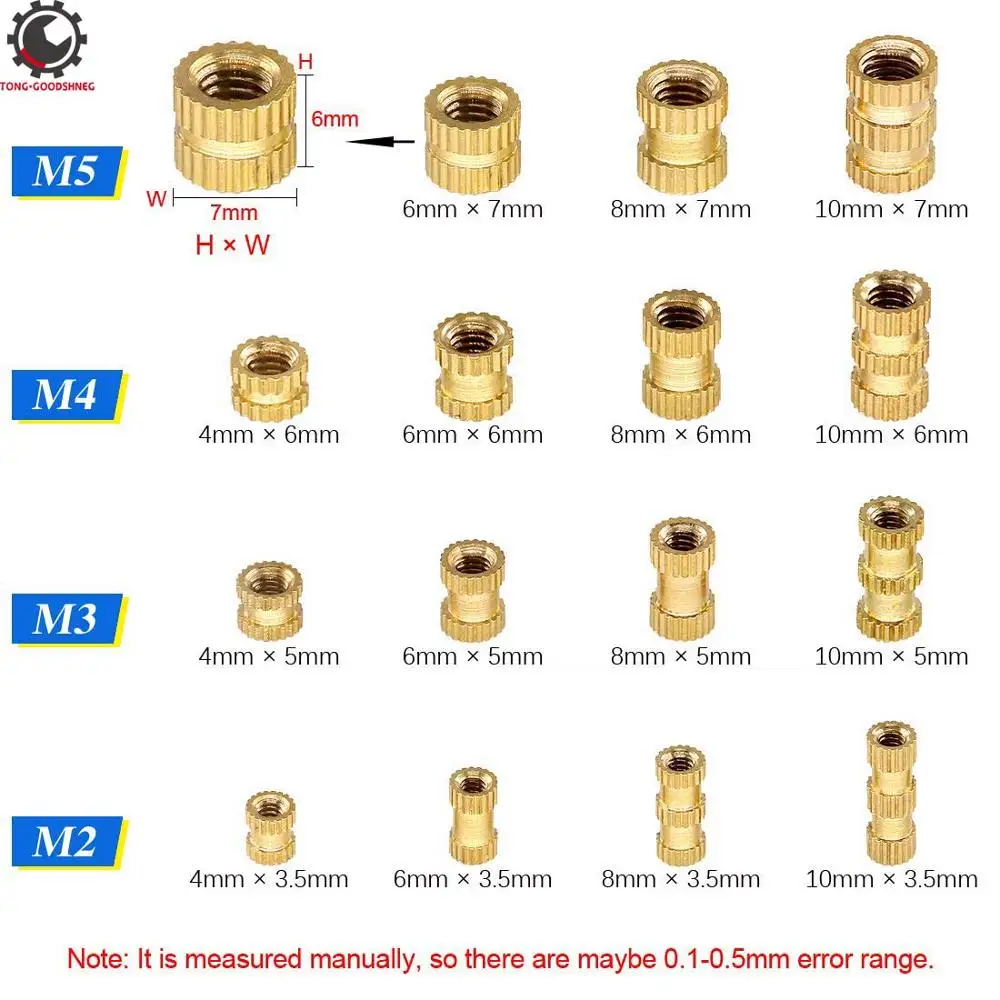

Threaded Insert Size Chart - Installation information preparation of external threads prior to installation (for keylocking. 1a, 2a, 3a, 1b, 2b or 3b. Inserts for external and internal applications. Inserts with an id thread 5/16 and above have four locking keys, smaller sizes have two. Locking keys are driven down into the parent material during installation, providing a positive mechanical lock against rotation. A threaded round insert consists of a tube with threads around its circumference. Install insert.010 to.030 below surface. Grade and with certificates of conformity on special order. A threaded insert with full thread is available in sizes ranging from m1.6 to m64+ in diameter. The size of the threaded insert should match the size of the hole in which it will be installed. The wide range of carbide threading grades from sandvik coromant offers high productivity for many materials and applications. Grade but can be supplied in milspec. Bend the keys down and break them off. Web standard thread turning inserts. Be sure to measure the hole accurately, as an insert that is too large or too small may not provide a secure. Bend the keys down and break them off. When it comes to sizing holes for inserts, i’d recommend following the dimensional info that comes with the insert datasheets. Inserts for external and internal applications. Web standard thread turning inserts. Web drill threads the insert. From 1/4″ and above the diameters are given in inch fractions. When it comes to sizing holes for inserts, i’d recommend following the dimensional info that comes with the insert datasheets. Nominal diameter in inch fraction. Drill the insert to the size and depth shown under removal data in the chart below. Installation information preparation of external threads prior to. It is important to use internal inserts with internal tool holders, and vice versa, to ensure that the correct thread form is achieved. Drill the insert to the size and depth shown under removal data in the chart below. Web to set the correct radial clearance, the inserts are tilted 10° or 15° in the tool holder. Standard insert sizes. Bend the keys down and break them off. 1a, 2a, 3a, 1b, 2b or 3b. The size of the threaded insert should match the size of the hole in which it will be installed. Unc / unf / unef / un. Standard insert sizes 11, 16 and 22. Drill the insert to the size and depth shown under removal data in the chart below. It is important to use internal inserts with internal tool holders, and vice versa, to ensure that the correct thread form is achieved. The wide range of carbide threading grades from sandvik coromant offers high productivity for many materials and applications. Inserts with an. A threaded insert with full thread is available in sizes ranging from m1.6 to m64+ in diameter. Inserts with an id thread 5/16 and above have four locking keys, smaller sizes have two. Select the most suitable tool for the operation, and use the table to find the grade and geometry that best match the application requirements. Want to learn. Be sure to measure the hole accurately, as an insert that is too large or too small may not provide a secure connection. Drill the insert to the size and depth shown under removal data in the chart below. Unc / unf / unef / un. Locking keys are driven down into the parent material during installation, providing a positive. Grade and with certificates of conformity on special order. Locking keys are driven down into the parent material during installation, providing a positive mechanical lock against rotation. Want to learn more about our design guidelines? Standard insert sizes 11, 16 and 22. Select the most suitable tool for the operation, and use the table to find the grade and geometry. From 1/4″ and above the diameters are given in inch fractions. Grade but can be supplied in milspec. Threaded inserts reduce risk of cracking of installation material. Want to learn more about our design guidelines? Web updated on april 2, 2024. The size of the threaded insert should match the size of the hole in which it will be installed. Standard insert sizes 11, 16 and 22. When it comes to sizing holes for inserts, i’d recommend following the dimensional info that comes with the insert datasheets. It is important to use internal inserts with internal tool holders, and vice versa, to ensure that the correct thread form is achieved. Inserts with an id thread 5/16 and above have four locking keys, smaller sizes have two. 1a, 2a, 3a, 1b, 2b or 3b. Grade and with certificates of conformity on special order. Be sure to measure the hole accurately, as an insert that is too large or too small may not provide a secure connection. Locking keys are driven down into the parent material during installation, providing a positive mechanical lock against rotation. Want to learn more about our design guidelines? Select the most suitable tool for the operation, and use the table to find the grade and geometry that best match the application requirements. Web diameter (mm) drilling diameter. Drill the insert to the size and depth shown under removal data in the chart below. A threaded insert with full thread is available in sizes ranging from m1.6 to m64+ in diameter. A threaded round insert is specified by tube thickness, thread, and height. Installation information preparation of external threads prior to installation (for keylocking.

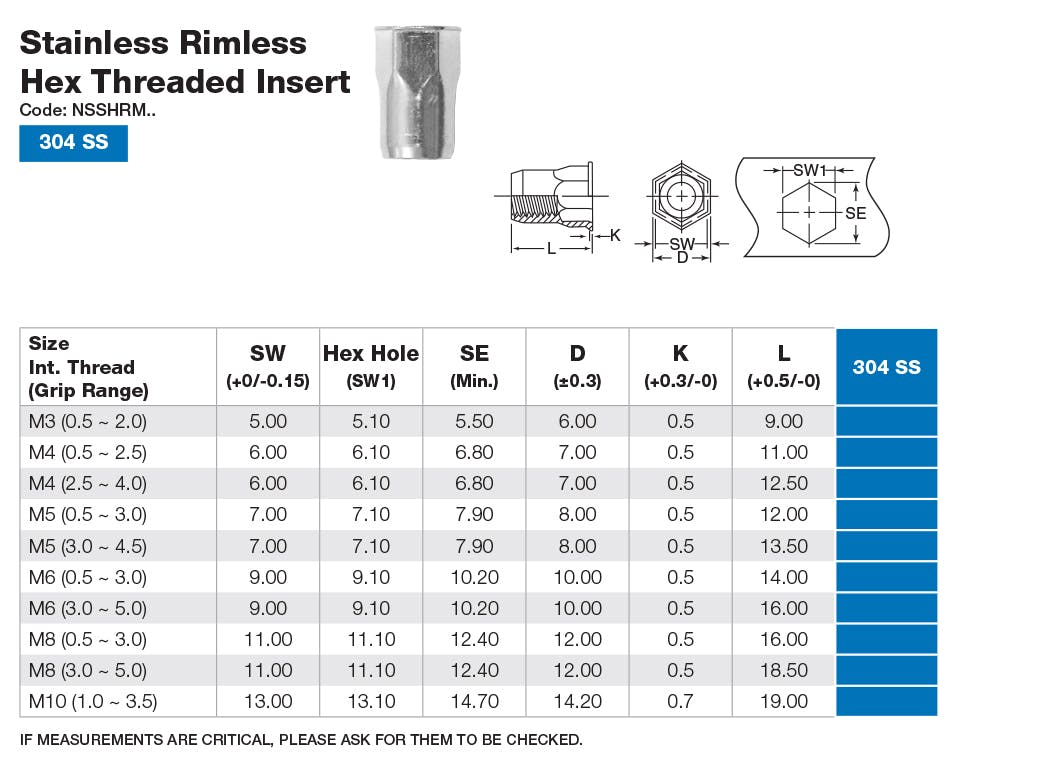

Stainless Threaded Insert Dimensions Anzor Fasteners

Threaded Insert Size Chart

Threaded Inserts for Plastic, Wood, Injection & Rotomolding Cross Tools Co

Threaded Inserts for Plastic, Wood, Injection & Rotomolding Cross Tools Co

CNC Kitchen Official Threaded Inserts

Stainless Rimless Threaded Insert Anzor Fasteners

Threaded Inserts The Wood Works Book & Tool Co.

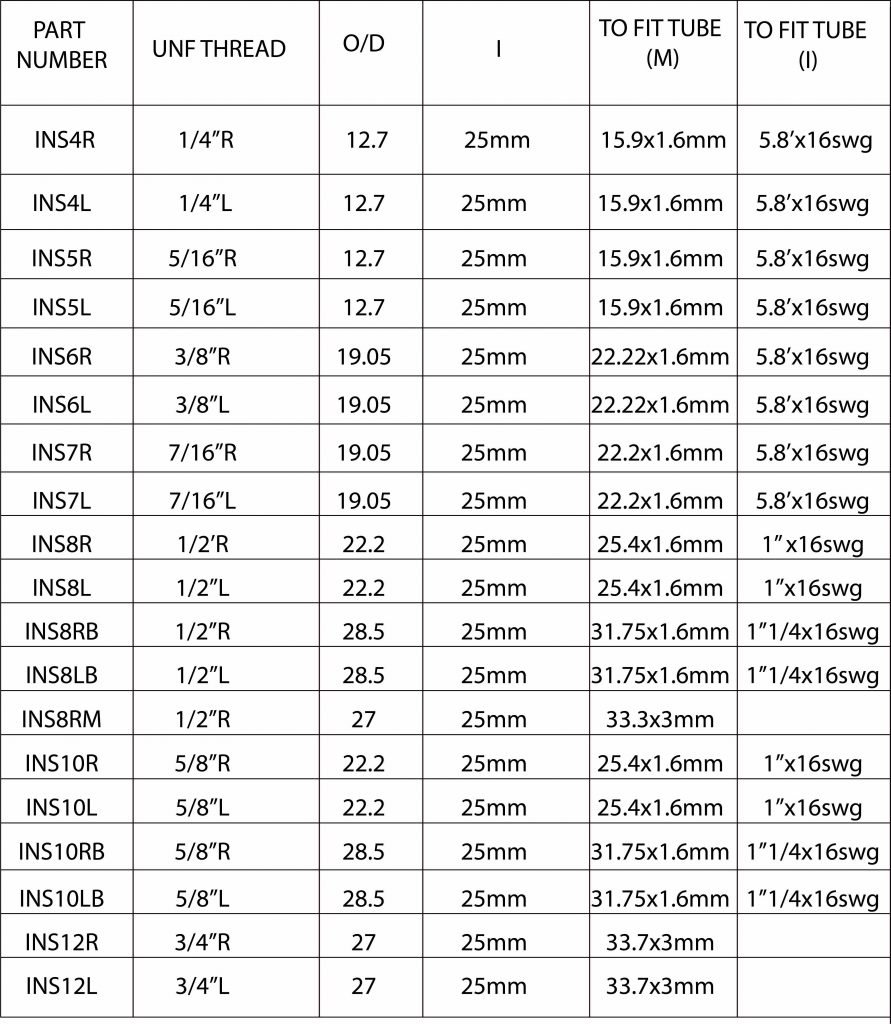

5/16″INSERTS TMR

Threaded Inserts for Plastic, Wood, Injection & Rotomolding Cross Tools Co

Threaded Insert Size Chart

Unc / Unf / Unef / Un.

Bend The Keys Down And Break Them Off.

Web To Set The Correct Radial Clearance, The Inserts Are Tilted 10° Or 15° In The Tool Holder.

Threaded Inserts Reduce Risk Of Cracking Of Installation Material.

Related Post: