Tig Welder Settings Chart

Tig Welder Settings Chart - Troubleshooting guide for tig welding. A flow of 15 to 25 cfh will cover most applications. Tig welder inverters have a bunch of settings and if you don’t understand what they do, you will never get the most out of your inverter tig welding machine. Web understanding the basics of tig welding steel settings. Web in this article, we’ll explain the various tig welder settings and waveform controls, including amperage, gas flow rate, and more advanced like pulse, ac features, and dc controls. Web the use of tig welding for aluminum has many advantages for both manual and automatic processes. Dc is typically used for welding steel, as it offers a stable arc and better penetration than ac. We need a lot less flow in tig welding. Web an aluminum tig welding settings chart provides essential parameters like amperage and gas flow. Web what metal are you welding? Never operate any equipment without carefully reading, understanding, and following all of the related safety rules and. Web when welding aluminum, the amperage should be on “ac.” on the other hand, if you’re welding steel, keep the amperage on “dc.” if you have a machine that is ac and dc compatible, it’ll typically automatically choose one when you turn the. A flow of 15 to 25 cfh will cover most applications. Get precise settings for metal, electrode, and amperage. And is intended for use by experienced personnel. The information in this manual represents the best judgement of ck worldwide, inc. Web follow requirements in osha 1910.252 (a) (2) (iv) and nfpa 51b for hot work and have a fire watcher. A flow of 15 to 25 cfh will cover most applications. The three main types of metals typically worked on with a tig welder include steel, stainless steel, and aluminum. Browse suggested weld parameter settings for tig welding. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Web a tig welding settings chart is. Tungsten diameter and cup size. It outlines the optimal settings based on material thickness and joint type. Tig welding can be used to weld aluminium, copper, titanium etc. Here you can find articles, videos, webinars and all things tig. Web tig welding chart based on material and shielding gas. Read and understand the safety data sheets (sdss) and the manufacturer’s instructions for adhesives, coatings, cleaners, consumables, coolants, degreasers, fluxes, and metals. We need a lot less flow in tig welding. Web a tig welding settings chart is an indispensable tool for welders, offering a roadmap to the ideal settings for various materials and thicknesses. Browse suggested weld parameter settings. Web an aluminum tig welding settings chart provides essential parameters like amperage and gas flow. Web what metal are you welding? Before powering your tig welder, you need to assemble the tig torch, choose your tungsten, and attach the shielding gas to the welder. By using the chart, welders can determine the optimal settings for their welding machine based on. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Filler metal can be either wire or rod and should be compatible with the base alloy. Get precise settings for metal, electrode, and amperage. Browse suggested weld parameter settings for tig welding. The three main types of metals typically worked on with a tig welder. Web download the app version of the weld setting calculator for easy reference! According to these charts, mild steel requires the most amperage (not aluminum), and also the fastest travel speed. Web see the chart below for current ranges of all sizes. The three main types of metals typically worked on with a tig welder include steel, stainless steel, and. Stainless is less thermally conductive than mild steel, so heat does not flow away from the weld quite so quickly. Web optimize tig welding with our free online tig welding calculator. Web setting up your tig welder for the first time. Before powering your tig welder, you need to assemble the tig torch, choose your tungsten, and attach the shielding. Here you can find articles, videos, webinars and all things tig. Web from setup to troubleshooting, learn more about the basics of tig welding and get tips for tig welding success. Select a topic below to get started. Never operate any equipment without carefully reading, understanding, and following all of the related safety rules and. Web view technical guides for. Web an aluminum tig welding settings chart provides essential parameters like amperage and gas flow. Filler metal must be dry, free of oxides, grease, or other foreign matter. Web the use of tig welding for aluminum has many advantages for both manual and automatic processes. And is intended for use by experienced personnel. The amperage required when tig welding is highly affected by the type of metal you are working with and how thick that metal is. The choice between alternating current (ac) and direct current (dc) plays a pivotal role in tig welding. It outlines the optimal settings based on material thickness and joint type. The information in this manual represents the best judgement of ck worldwide, inc. Troubleshooting guide for tig welding. Web view technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for your application. Web i have three charts here, all from the same source (ck worldwide technical specifications for tig welding), but they seem to contradict everything i've heard. And even two dissimilar metals. Web in this article, we’ll explain the various tig welder settings and waveform controls, including amperage, gas flow rate, and more advanced like pulse, ac features, and dc controls. Web setting up your tig welder for the first time. The role of current type in tig welding. Web pulsed tig welding settings can seem complicated, but ron covell is here to help you set the right parameters and get the best results.

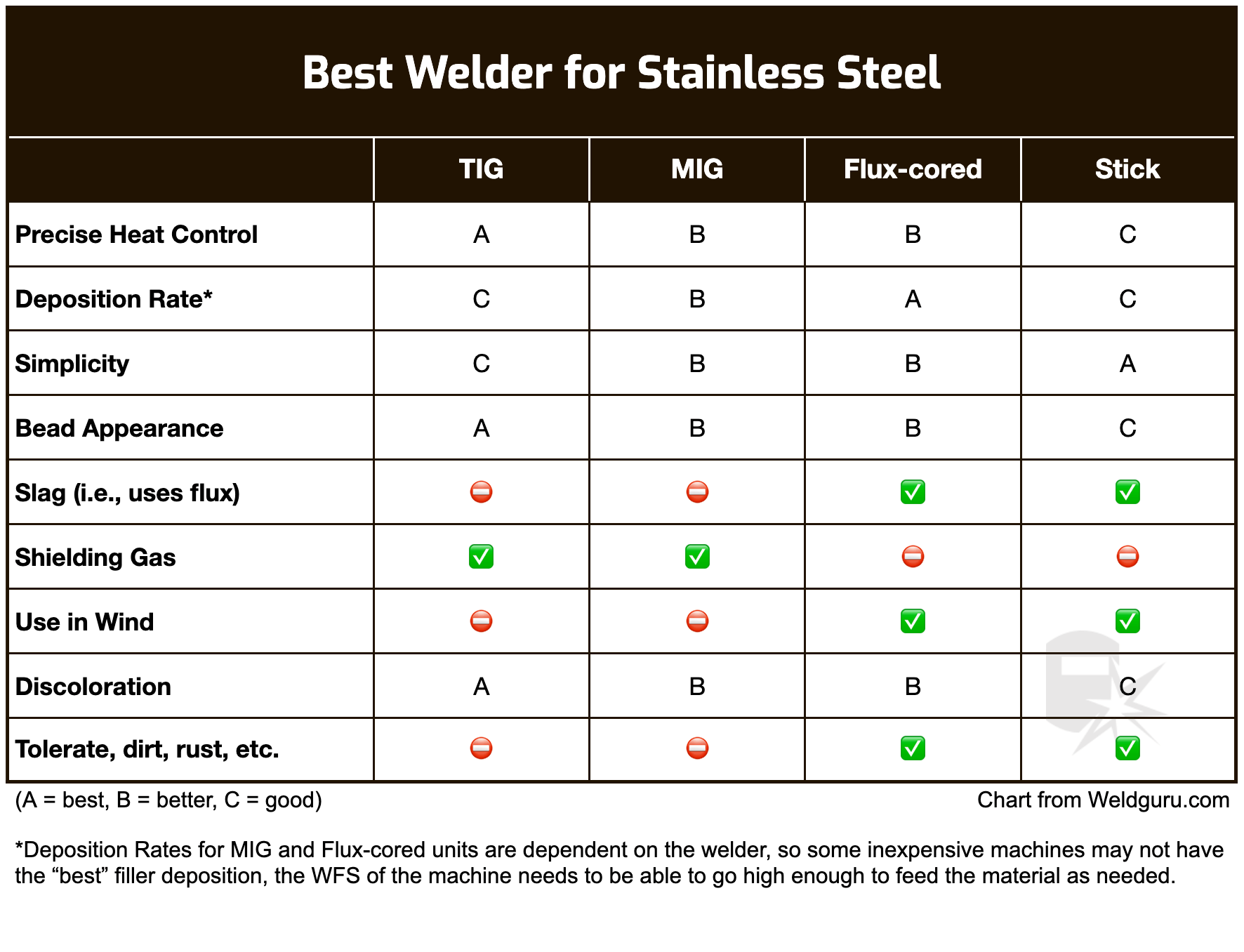

How to Weld Stainless Steel A Complete Guide (2022)

Tig Welding Settings Chart Pdf

Tig Welder Settings Chart

Tig Welding Rods Chart

Tig parameters chart MIG Welding Forum

Aluminum Tig Welding Settings Chart

TIG Welding Charts ILMO Products Company

TIG Tungsten Electrodes Explained (with Color Chart)

Aluminum Tig Welding Settings Chart

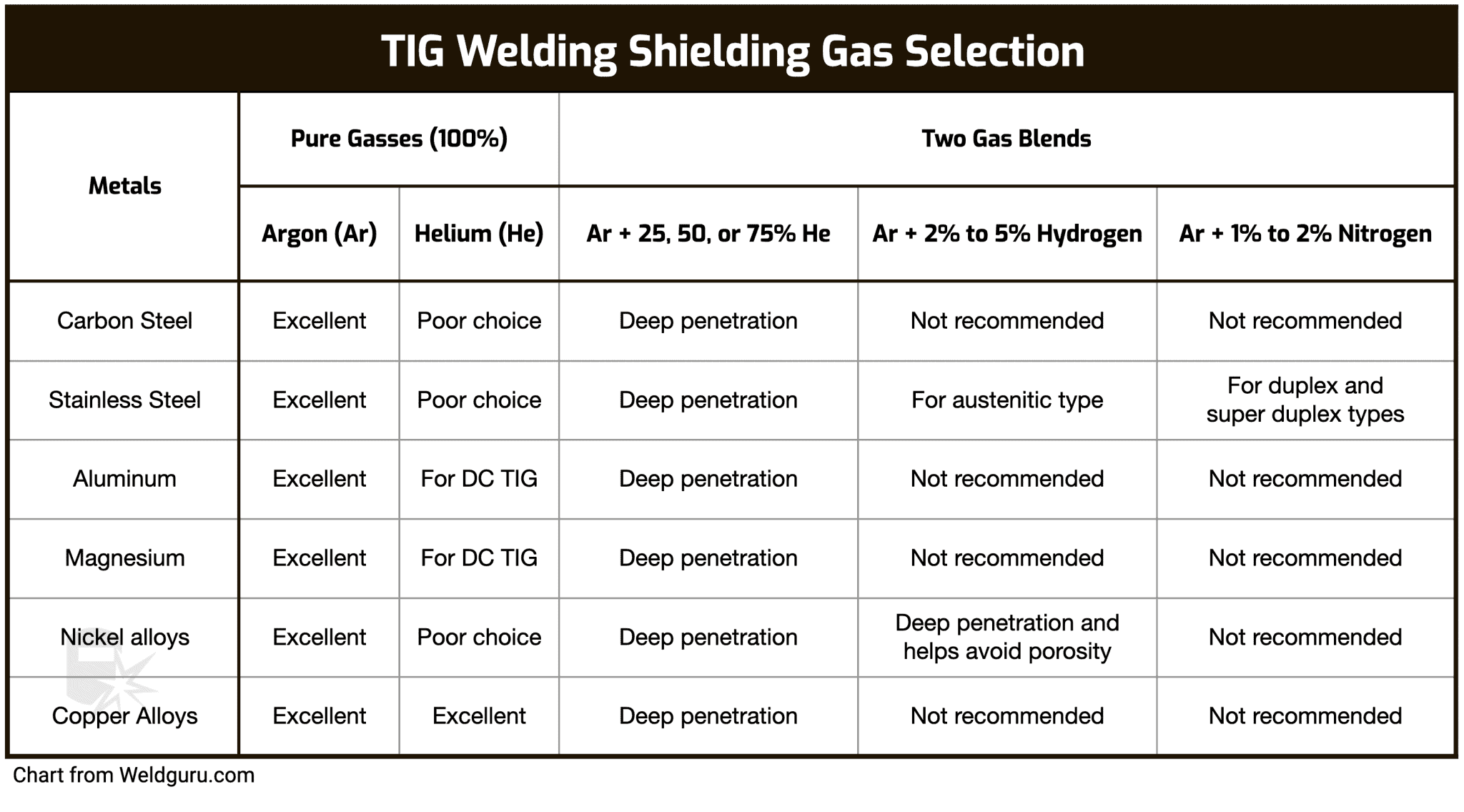

What Gas Should You Use for TIG Welding? (with Chart)

Web When Welding Aluminum, The Amperage Should Be On “Ac.” On The Other Hand, If You’re Welding Steel, Keep The Amperage On “Dc.” If You Have A Machine That Is Ac And Dc Compatible, It’ll Typically Automatically Choose One When You Turn The Machine On, So Check Closely And Adjust When Necessary.

Here You Can Find Articles, Videos, Webinars And All Things Tig.

Browse Suggested Weld Parameter Settings For Tig Welding.

The Three Main Types Of Metals Typically Worked On With A Tig Welder Include Steel, Stainless Steel, And Aluminum.

Related Post: