Wl Plastics Pipe Chart

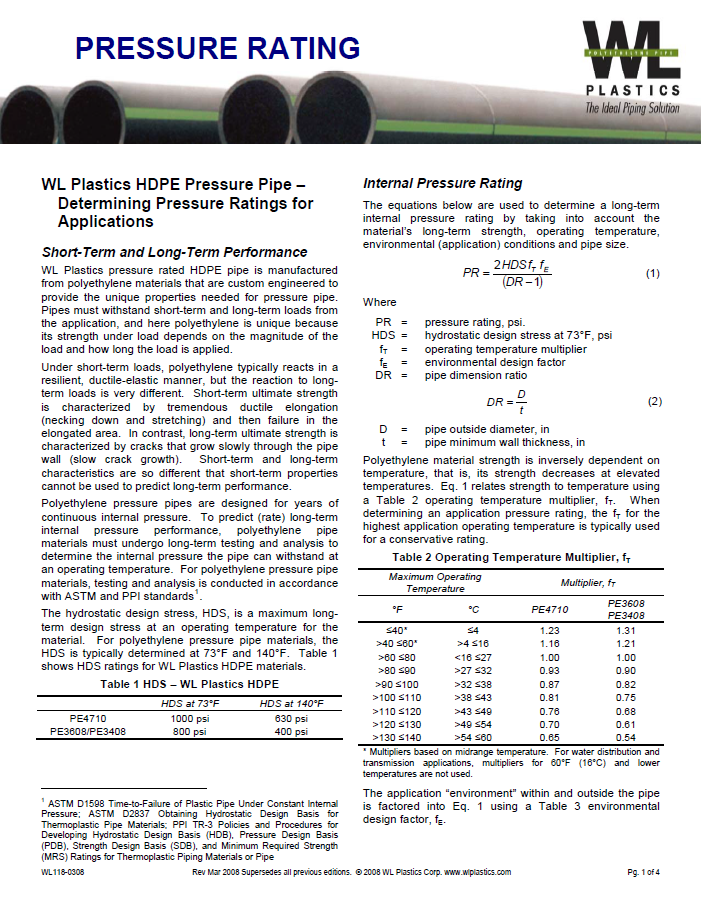

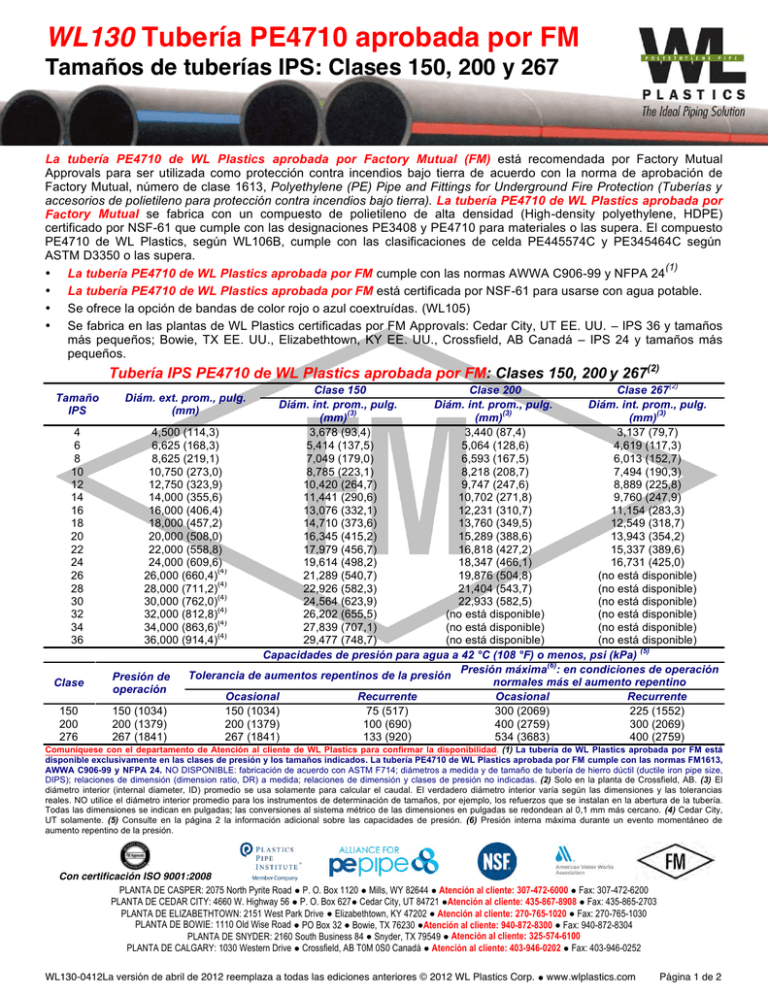

Wl Plastics Pipe Chart - Web astm's plastic pipe standards are instrumental in specifying, testing, and evaluating the physical, mechanical, design, and installation requirements for plastic, polymeric, or elastomeric pipes, tubing, and fittings, including the seals, threads, and couplings that. Web wl plastics dips pressure class pipe is produced in pc250, pc200, pc150 and pc100 in pe4710 and pe3608 compounds. Pressure class is for continuous internal water pressure at 80of (2 7oc) and lower temperatures and includes surge pressure. Wl plastics acquires charter plastics hdpe pipe business. The chart includes submerges sizes ranging from 4 to 36. The pe4710 material conforms to astm d3350 with the cell. It should only be used where the sizes, pressures and temperatures will not support condensation. Wl plastics pressure rated hdpe pipe is manufactured from polyethylene materials that are custom engineered to provide the. Our high quality polyethylene (hdpe & mdpe) pipe provides durability to avoid the high cost of replacing or rehabilitating. Maximum flow occurs at about 93% of full pipe flow, and. Web industry standards for wl plastics pipe. It is responsibility of designers to consider the life expectancy of plastic pipe when selecting the pipe. Web iron pipe size (ips) average outer diameter (od) dimension ratio (dr) 1172: Web this size chart tabbed this dips (ductile iron single size) and diod (ductile iron outside diameter) piping sizes and pressure class ratings. Web iron pipe size (ips) average outer diameter (od) dimension ratio (dr) 1172: Web wl plastics is the largest manufacturer of polyethylene pipe in north america offering both high density polyethylene (hdpe) and medium density polyethylene (mdpe) pipe solutions. Web industry standards for wl plastics pipe. Wl102, 0.153 inch (in) minimum wall thickness high density polyethylene (hdpe) 140 pound per. It should only be used where the sizes, pressures and temperatures will not support condensation. Jmm hdpe pressure pipe is manufactured with premium, highly engineered pe4710 resin that provides maximum performance benefits to service today’s municipal and industrial water needs. Web circular pipes will carry more liquid when slightly less than full compared to completely full because there is a. We carry a range of pipe sizes to suit various applications. It should only be used where the sizes, pressures and temperatures will not support condensation. Pcb, psi 335 320 250 200 160 140 125 100 80 65. Web industry standards for wl plastics pipe. Wl102, 0.153 inch (in) minimum wall thickness high density polyethylene (hdpe) 140 pound per square. Us federal regulations specify the 73°f (23°c) rating for 100°f (38°c) and below. Web wl plastics hdpe pipe is produced to customer purchase order specifications, and may be limited by industry standards and third party certifications. The pe4710 material conforms to astm d3350 with the cell. This size chart lists the ips (iron pipe size) pipe sizes and pressure class. The information in this publication is for estimating purposes only. The pe4710 material conforms to astm d3350 with the cell. Maximum flow occurs at about 93% of full pipe flow, and. Us federal regulations specify the 73°f (23°c) rating for 100°f (38°c) and below. Web circular pipes will carry more liquid when slightly less than full compared to completely full. Web pipe dr 5.0 fps velocity change 1.0 fps velocity change 17 56.3 psig 11.3 psig 11 71.9 psi g14.4 psi 9 80.9 psig 16.2 psig pressure class, surge allowance and corresponding sudden velocity change for wl plastics pe 3408 pipe operating at service. The ineos’ wholly owned subsidiary expands its hdpe pipe business through new acquisition. Us federal regulations. Web industry standards for wl plastics pipe. Truckload quantities herein were developed for a maximum load weight of 47,000 lbs (21,315 kg). The chart includes submerges sizes ranging from 4 to 36. Web wl plastics is the largest manufacturer of polyethylene pipe in north america offering both high density polyethylene (hdpe) and medium density polyethylene (mdpe) pipe solutions. See wl102a. Wl plastics acquires charter plastics hdpe pipe business. Web regulations limit maximum pe pipe operating pressure (maop) to 125 psi for 12” ips and smaller pipes or 100 psi for >12” ips through 24” ips. The following resources are helpful when selecting the right pipe size for a specific application: Wl102, 0.153 inch (in) minimum wall thickness high density polyethylene. The temperature factor, ft, is applied. Web wl plastics is the largest manufacturer of polyethylene pipe in north america offering both high density polyethylene (hdpe) and medium density polyethylene (mdpe) pipe solutions. It is responsibility of designers to consider the life expectancy of plastic pipe when selecting the pipe. See wl102a and wl102b for weight per foot for ips sized. The chart includes submerges sizes ranging from 4 to 36. Wl plastics typically manufactures pipe in accordance with the api, astm, awwa, fm, nsf and aashto. Web wl plastics hdpe pipe is produced to customer purchase order specifications, and may be limited by industry standards and third party certifications. Web pipe dr 5.0 fps velocity change 1.0 fps velocity change 17 56.3 psig 11.3 psig 11 71.9 psi g14.4 psi 9 80.9 psig 16.2 psig pressure class, surge allowance and corresponding sudden velocity change for wl plastics pe 3408 pipe operating at service. Maximum flow occurs at about 93% of full pipe flow, and. Wl plastics fm approved pipe is listed by factory mutual approvals for underground fire protection service in accordance with factory mutual approval standard class number 1613,. Pcb, psi 335 320 250 200 160 140 125 100 80 65. Us federal regulations specify the 73°f (23°c) rating for 100°f (38°c) and below. Web wl plastics dips pressure class pipe is produced in pc250, pc200, pc150 and pc100 in pe4710 and pe3608 compounds. Our high quality polyethylene (hdpe & mdpe) pipe provides durability to avoid the high cost of replacing or rehabilitating. The pe4710 material conforms to astm d3350 with the cell. Wl plastics acquires charter plastics hdpe pipe business. Web this size chart tabbed this dips (ductile iron single size) and diod (ductile iron outside diameter) piping sizes and pressure class ratings for our pe4710 pipe. It should only be used where the sizes, pressures and temperatures will not support condensation. Web circular pipes will carry more liquid when slightly less than full compared to completely full because there is a slight reduction in flow area compared to a significant reduction in the wetted surface of the pipe. Web this size chart lists the dips (ductile iron pipe size) and diod (ductile iron outside diameter) pipe sizes and pressure class ratings for magnitude pe4710 pipe.

Wl Plastics Pipe Chart

Wl Plastics Pipe Chart chartdevelopment

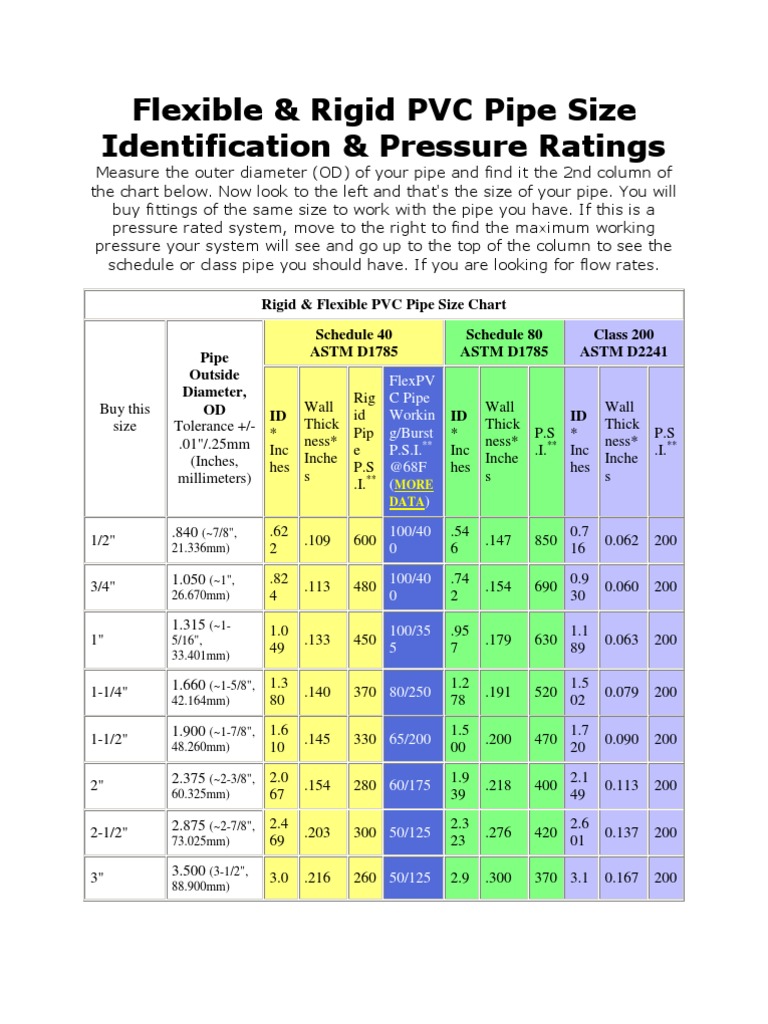

Pvc Pipe Dimension Chart

Wl Plastics Pipe Chart chartdevelopment

Plastic Pipe Sizes for sale in UK 58 used Plastic Pipe Sizes

Wl Plastics Pipe Chart chartdevelopment

Wl Plastics Pipe Chart chartdevelopment

Technical Hub ISCO Industries

HDPE WL Plastics

Wl Plastics Pipe Chart chartdevelopment

The Information In This Publication Is For Estimating Purposes Only.

Web Iron Pipe Size (Ips) Average Outer Diameter (Od) Dimension Ratio (Dr) 1172:

Web Wl Plastics Is The Largest Manufacturer Of Polyethylene Pipe In North America Offering Both High Density Polyethylene (Hdpe) And Medium Density Polyethylene (Mdpe) Pipe Solutions.

Web Industry Standards For Wl Plastics Pipe.

Related Post: