Wood Kiln Drying Time Chart

Wood Kiln Drying Time Chart - Web an explanation of the basics of kiln drying wood, a list of the most commonly used methods and drying schedules and defects. Uniformity of drying and the quality of the wood in a kiln are strongly influenced by the. You need to consider these wetter. A numerical model that simulates the airflow distribution is described. Wood drying (also seasoning lumber or wood seasoning) reduces the moisture content of wood before its use. Through all the phases of a lumber mill, controlling moisture is key to producing a quality end product. Osha standards regarding dry kiln facilities. Can drying cause the wood to split or check? Decide if it is a hobby or a business ? Wood does shrink while it dries, but the shrinking doesn’t start until the lumber is A kiln schedule is a set of temperatures and humidities that are used during kiln operation. Web decide on a drying schedule. How to measure mc in wood. Can drying cause the wood to split or check? Web commercial kilns use different methods for drying hardwoods and softwoods. Decide if it is a hobby or a business ? How to measure mc in wood. These two values, when combined, should roughly add up to the volumetric shrinkage. Schedules for several thicknesses and specialty products (e.g. Web hardwood lumber kiln schedules. Make sure the frame is square and level before you move on. Decide if it is a hobby or a business ? How to measure mc in wood. You need to consider these wetter. Building the frame is probably the most challenging part of this project. Decide if it is a hobby or a business ? How to remove moisture from wood. Wood does shrink while it dries, but the shrinking doesn’t start until the lumber is Applied to solve the flow distribution in a kiln. This will be the shell of your kiln. Operators constantly monitor kiln temperatures and relative humidity (rh), as well as. Freshly sawn red oak is considered to be 75% mc, but some pieces will be 90% mc or even higher. Osha standards regarding dry kiln facilities. Web hardwood lumber kiln schedules. The constant or ovendry weight and the weight of the specimen when cut are used to determine. Smaller specimens will take less time. Building the frame is probably the most challenging part of this project. Wood drying (also seasoning lumber or wood seasoning) reduces the moisture content of wood before its use. Web an explanation of the basics of kiln drying wood, a list of the most commonly used methods and drying schedules and defects. Generally speaking,. Web however, each type of sawn lumber responds differently in drying. The dry kiln operator’s manual provides numerous kiln schedules based on wood species, thickness, starting moisture content, the part of the tree the wood is from, and the way the wood has been cut. Smaller specimens will take less time. Understanding the drying time for wood is crucial for. Wood does shrink while it dries, but the shrinking doesn’t start until the lumber is How to remove moisture from wood. You need to consider these wetter. The dry kiln operator’s manual provides numerous kiln schedules based on wood species, thickness, starting moisture content, the part of the tree the wood is from, and the way the wood has been. Web this report contains suggested dry kiln schedules for over 500 commercial woods, both temperate and tropical. These two values, when combined, should roughly add up to the volumetric shrinkage. Building the frame is probably the most challenging part of this project. Web hardwood lumber kiln schedules. Squares, handle stock, gunstock blanks) are given for many species. Flatsawn lumber is less susceptible to collapse, shrinks and swells less in thickness, and dries faster than quartersawn. Go to a kiln operator’s short course. Wood drying (also seasoning lumber or wood seasoning) reduces the moisture content of wood before its use. Web however, each type of sawn lumber responds differently in drying. How to remove moisture from wood. Generally speaking, drying times are roughly proportional to the thickness. The majority of the schedules are. Go to a kiln operator’s short course. Osha standards regarding dry kiln facilities. The dry kiln operator’s manual provides numerous kiln schedules based on wood species, thickness, starting moisture content, the part of the tree the wood is from, and the way the wood has been cut. Web drying times can vary significantly depending upon wood species, initial moisture level, lumber thickness, density, ambient conditions, and processing techniques. How to remove moisture from wood. Squares, handle stock, gunstock blanks) are given for many species. This will be the shell of your kiln. The schedules can follow a timetable or moisture content measurements. Make sure the frame is square and level before you move on. Kiln schedules are completely assembled and written out for easy use. Wood does shrink while it dries, but the shrinking doesn’t start until the lumber is Web commercial kilns use different methods for drying hardwoods and softwoods. Many factors impact drying time, including local climate, time of year wood is harvested, and the species. These two values, when combined, should roughly add up to the volumetric shrinkage.

Kiln schedule applied for drying G. arborea boards Download Table

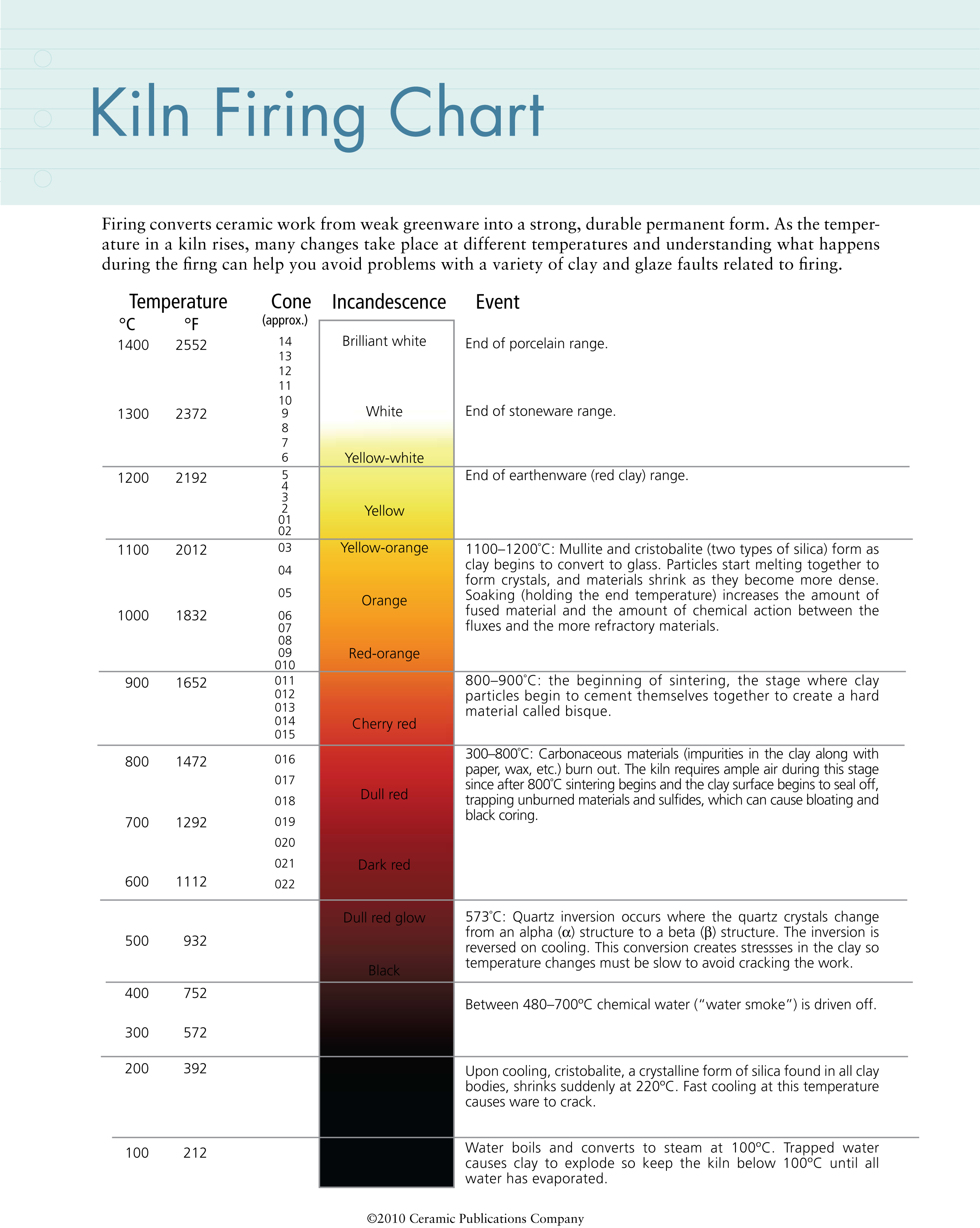

Kiln Firing Chart

Table 2 from STATISTICAL ANALYSIS OF SIMULATED WOOD DRYING SCHEDULES AS

Dif1 kiln drying schedule for P. fortunei lumber with 5 cm thickness

Kiln schedules used for the conventional drying of A. mangium wood

How To Kiln Dry Wood

Approximate Drying Times for Various Woods woodworking

Vacuum kiln drying

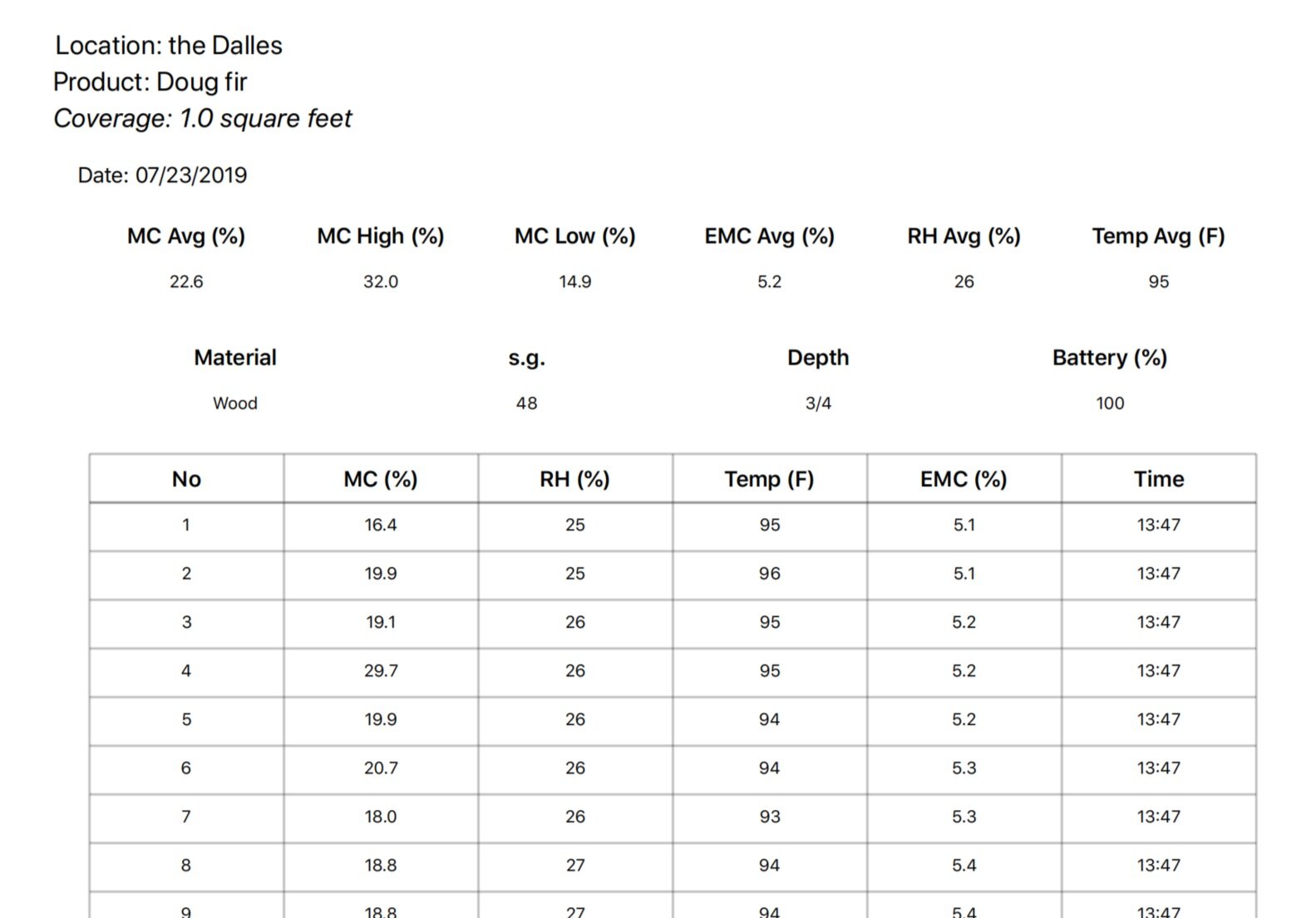

How Dry is Home Depot Kiln Dried Lumber? — Blacktail Studio

Hardwood Lumber Kiln Schedules

Rapid Log Turnover Is One Of The Most Cost Effective Ways To Avoid Problems.

Log Protection Is Critical To Avoid Stain And Splits.

The Constant Or Ovendry Weight And The Weight Of The Specimen When Cut Are Used To Determine The Percentage Of Moisture Content Using.

Schedules For Several Thicknesses And Specialty Products (E.g.

Related Post: