Mig Amp Chart

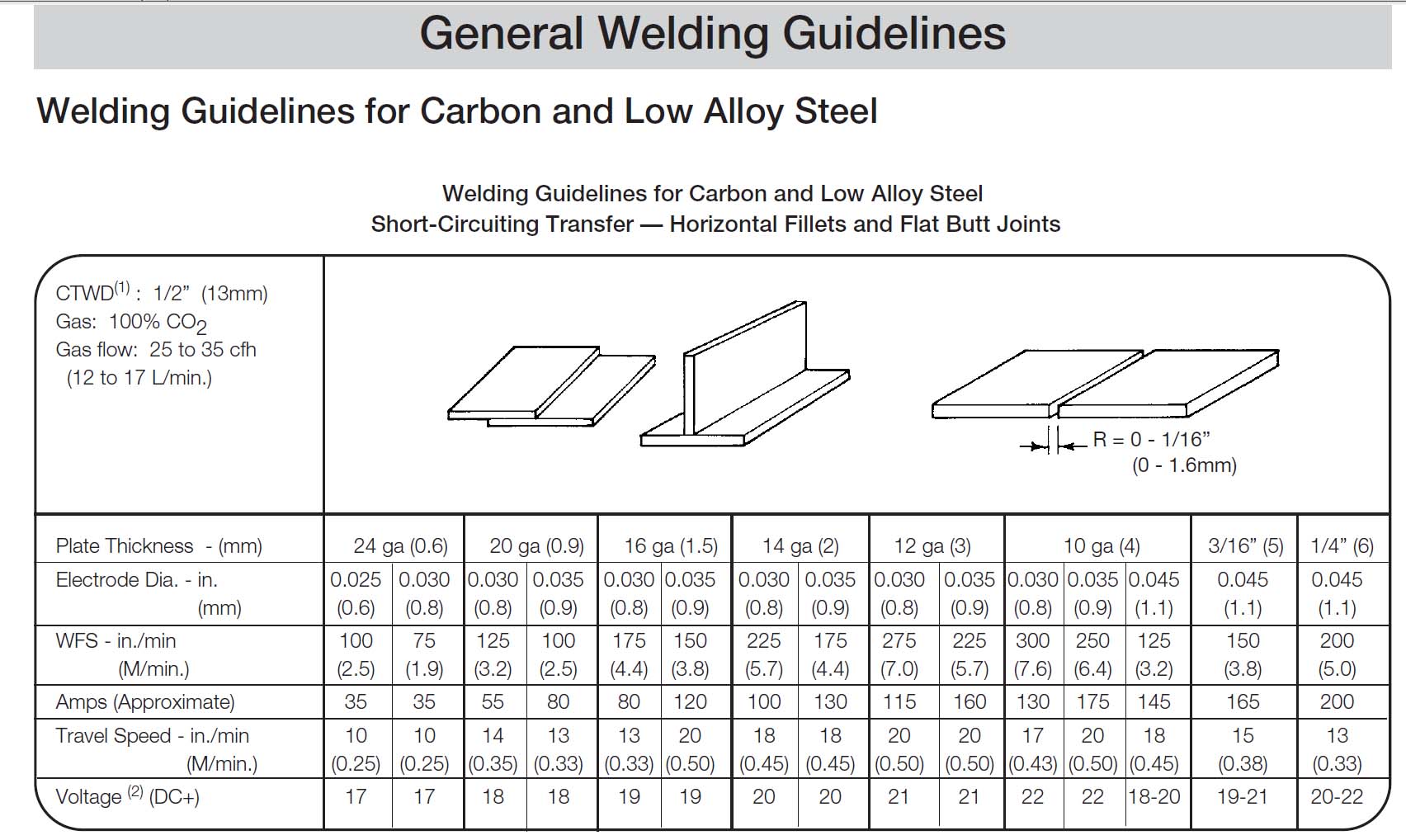

Mig Amp Chart - To help determine the proper amperage for your needs, use the chart. Beginners guide (with chart) by: What material are you welding? .125 inch = 125 amps. Mig welding wire output amperage & selection chart. How to use the calculator. A mig wire size chart provides recommended wire diameters for different metal thicknesses. Web setting the amperage on a welding machine, whether stick (smaw), mig (gmaw) (*typically uses voltage setting), or tig (gtaw), depends on some key variables such. Web as a guideline, each.001 inch of material thickness requires 1 amp of output: In making a mig wire purchase, your last decision involves the quantity of wire and how it’s housed. Web how to mig weld aluminum: Select proper wire size according to amperage. These figures can be found from manufacturer or retailers' specs. The amp range overlaps, giving you various options for each current setting. Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. Web flux cored welding calculator. What material are you welding? Whether you’re a beginner or an experienced welder, this page has all the. To start the pictures above. Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. Whether you’re a beginner or an experienced welder, this page has all the. Mig welding wire output amperage & selection chart. Web download the app version of the weld setting calculator for easy reference! Web the amount of amps required to weld two pieces of metal depends on the thickness and type of metal. Web mig welder settings charts, guides. Whether you’re a beginner or an experienced welder, this page has all the. .125 inch = 125 amps. Web download the app version of the weld setting calculator for easy reference! These figures can be found from manufacturer or retailers' specs. Web setting the amperage on a welding machine, whether stick (smaw), mig (gmaw) (*typically uses voltage setting), or tig. Web here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: Web the amount of amps required to weld two pieces of metal depends on the thickness and type of metal. The size of your wire and. A mig wire size chart provides recommended wire diameters for different. Web mig welder settings charts, guides and tables for steel, stainless and aluminum lincoln mig welding electrode and gas selection chart settings. A mig wire size chart provides recommended wire diameters for different metal thicknesses. Web download the app version of the weld setting calculator for easy reference! Whether you’re a beginner or an experienced welder, this page has all. Web download the app version of the weld setting calculator for easy reference! Web your mig welding wire size will determine the amperage setting used. Beginners guide (with chart) by: Web february 26, 2024november 28, 2023 by sohagarbin. The amp range overlaps, giving you various options for each current setting. A higher wire speed requires a higher voltage to. To start the pictures above. Amperage, measured in amperes (a), refers to the amount of electrical current flowing through the welding circuit. Mig welding wire output amperage & selection chart. Web flux cored welding calculator. Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. Beginners guide (with chart) by: These figures can be found from manufacturer or retailers' specs. Web february 26, 2024november 28, 2023 by sohagarbin. Web a general rule of thumb is you need 1 amp of power for. What material are you welding? Whether you’re a beginner or an experienced welder, this page has all the. Web setting the amperage on a welding machine, whether stick (smaw), mig (gmaw) (*typically uses voltage setting), or tig (gtaw), depends on some key variables such. To help determine the proper amperage for your needs, use the chart. .125 inch = 125. Web mig welder settings charts, guides and tables for steel, stainless and aluminum lincoln mig welding electrode and gas selection chart settings. The amp range overlaps, giving you various options for each current setting. Whether you’re a beginner or an experienced welder, this page has all the. Web find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. Web february 26, 2024november 28, 2023 by sohagarbin. These figures can be found from manufacturer or retailers' specs. What material are you welding? Web setting the wire speed for mig welding involves understanding the correlation between wire speed, voltage, and amperage. To start the pictures above. Web setting the amperage on a welding machine, whether stick (smaw), mig (gmaw) (*typically uses voltage setting), or tig (gtaw), depends on some key variables such. Web download the app version of the weld setting calculator for easy reference! .125 inch = 125 amps. A mig wire size chart provides recommended wire diameters for different metal thicknesses. It directly affects the size and strength of the weld. The size of your wire and. Web the amount of amps required to weld two pieces of metal depends on the thickness and type of metal.

How To MIG Weld Aluminum Beginners Guide (with Chart)

Important MIG Welder Settings You Need to Know (with Chart)

pear user Wink aluminum mig welding settings chart intentional Have

MIG settings for welding different thickness mild steel

242 MIG Settings Chart PDF Metalworking Metals

Aluminum Mig Welding Amperage Chart

Mig Welding Amps To Metal Thickness Chart

MIG welder settings explained Amperage & Wire Speed

How To MIG Weld Aluminum Beginners Guide (with Chart)

Mig welder options, Old machine vs new MIG Welding Forum

Beginners Guide (With Chart) By:

Web A General Rule Of Thumb Is You Need 1 Amp Of Power For Every 0.001 Inches Of Steel.

How To Use The Calculator.

Web As A Guideline, Each.001 Inch Of Material Thickness Requires 1 Amp Of Output:

Related Post: