Size Of Welding Rod Chart

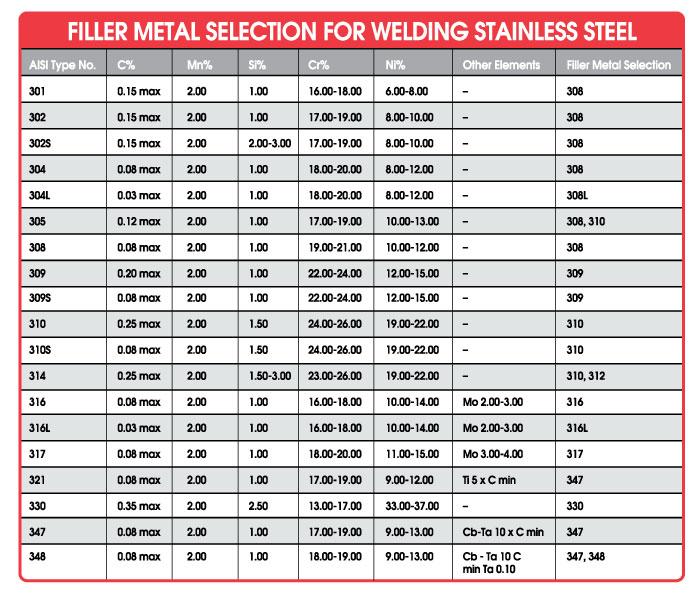

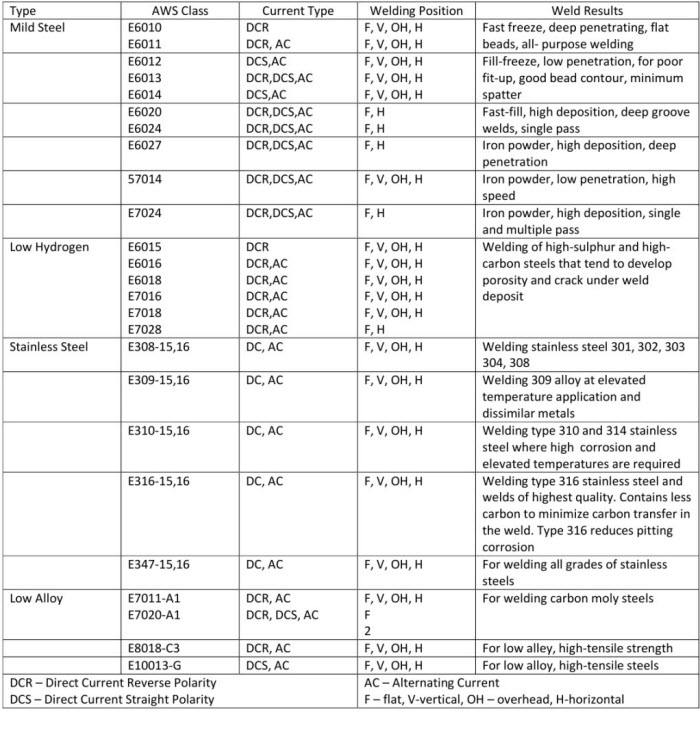

Size Of Welding Rod Chart - We cover everything related to rod types, sizes, and how to pick the right one for your needs. It would interest you to know that each of these rods has varied characteristics, such as tensile strength, position, penetration, and others. Contents [ show] common stick welding rods. You should not be perplexed with these numbers for these numbers correspond to certain values. Factors include penetration, joint access for slag removal, material thickness, and surface cleanliness. Understanding stick welding rod classification is essential in selecting the correct electrode for your welding needs. 1/8” and 5/32” are also very common. The table is published in aws a5.1 specification. Web see our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. You can’t use a rod that doesn’t run on your power supply. Web this chart provides an overview of the most common stick welding rod sizes and their corresponding classifications. Web welding rod sizes with amperage chart. Two of the setup variables you must get right when tig welding involves the choice of filler material and the tungsten electrode in your torch. Different welding rods sizes, types, and their uses. The chart. How to measure the diameter of a welding rod. You can use below welding rod sizes chart to choose the welding amperage for different diameters of welding rods used for carbon steel welding. Web welding rod sizes with amperage chart. An electrode is a metal wire that is coated. You can’t use a rod that doesn’t run on your power. We cover everything related to rod types, sizes, and how to pick the right one for your needs. Factors include penetration, joint access for slag removal, material thickness, and surface cleanliness. Larger diameter welding rods are only really needed for welding 1/2” and above, so won’t be used on your average home welding project. You can’t use a rod that. Web if you are looking for welding rod charts, we created the ultimate resource, listing everything from electrode sizes and amps to how much welding rod you need In this article, i’ll cover the most common welding rod sizes to help you pick the most suitable one for your needs. Web the most popular welding rod sizes for home welders. Contents [ show] common stick welding rods. Instead, you would choose the largest electrode to give you a perfect 1/8″ fillet weld. The table is published in aws a5.1 specification. Web the primary factor when choosing the size of a welding rod is the thickness of the base metal that’s going to be welded. All the common arc welding electrodes. Larger diameter welding rods are only really needed for welding 1/2” and above, so won’t be used on your average home welding project. In this article, i’ll cover the most common welding rod sizes to help you pick the most suitable one for your needs. It is made out of materials with a similar composition to the metal being welded.. Contents [ show] common stick welding rods. The welding rod should be thinner than the base metal but not thinner than half of the base metal. Factors include penetration, joint access for slag removal, material thickness, and surface cleanliness. The thicker the base metal, the larger the welding rod diameter and amperage. Understanding stick welding rod classification is essential in. The welding rod should be thinner than the base metal but not thinner than half of the base metal. Chart for different welding positions. The table is published in aws a5.1 specification. Web the primary factor when choosing the size of a welding rod is the thickness of the base metal that’s going to be welded. Web welding rod size. Web home » welders » stick welders. In this article, i’ll cover the most common welding rod sizes to help you pick the most suitable one for your needs. The welding rod should be thinner than the base metal but not thinner than half of the base metal. They are 6010, 6011, 6012, 6013, while the rest is 7014, 7018,. What are the common sizes of tig welding rods? Web if you are looking for welding rod charts, we created the ultimate resource, listing everything from electrode sizes and amps to how much welding rod you need Different welding rods sizes, types, and their uses. You can’t use a rod that doesn’t run on your power supply. Web below is. One cable from your welding machine is clamped to the 'work', and the other cable which also comes from the arc welding machine is for the rod holder. An electrode is a metal wire that is coated. Web if you are a beginner in the welding industry, you may be confused upon looking at the welding rod classification, for you would readily notice that the welding rod chart have numerical digits. What are the common sizes of tig welding rods? You have fewer choices of electrodes, depending on your welding position: What are the most common stick rods for home. How to measure the diameter of a welding rod. There are a variety of factors that go into choosing the right electrode for each project. In this article, i’ll cover the most common welding rod sizes to help you pick the most suitable one for your needs. The chart above indicates the numerical relationship between amperes and welding rod sizes. Web the primary factor when choosing the size of a welding rod is the thickness of the base metal that’s going to be welded. It is made out of materials with a similar composition to the metal being welded. The table is published in aws a5.1 specification. Amperage is the strength of the direct current flowing through the rod during the weld. Web the most popular welding rod sizes for home welders are 3/32″, 1/8″, and 5/32″, as they are suitable for common projects. Web welding electrodes & filler rods explained.![Different Types of Welding Rods & Their Uses [Explained] PDF](https://www.theengineerspost.com/wp-content/uploads/2022/07/Welding-Rods-1.jpg)

Different Types of Welding Rods & Their Uses [Explained] PDF

Welding Rod Sizes Chart

Welding Rod List

ER309L TIG Stainless Steel Welding Rod 36" All Sizes (Pack 1

The ultimate guide to welding rod sizes and classifications, including

Welding Rod Sizes Here's The Complete Guide

Welding Rod Chart

How Do I Calculate How Much Welding Rod I Need

Welding rod chart, Welding rods, Welding and fabrication

Arc Welding Rods Guide

It Would Interest You To Know That Each Of These Rods Has Varied Characteristics, Such As Tensile Strength, Position, Penetration, And Others.

Contents [ Show] Common Stick Welding Rods.

Overhead, Horizontal, Vertical, And Flat.

The Welding Rod Should Be Thinner Than The Base Metal But Not Thinner Than Half Of The Base Metal.

Related Post: