Tap And Drill Chart Metric

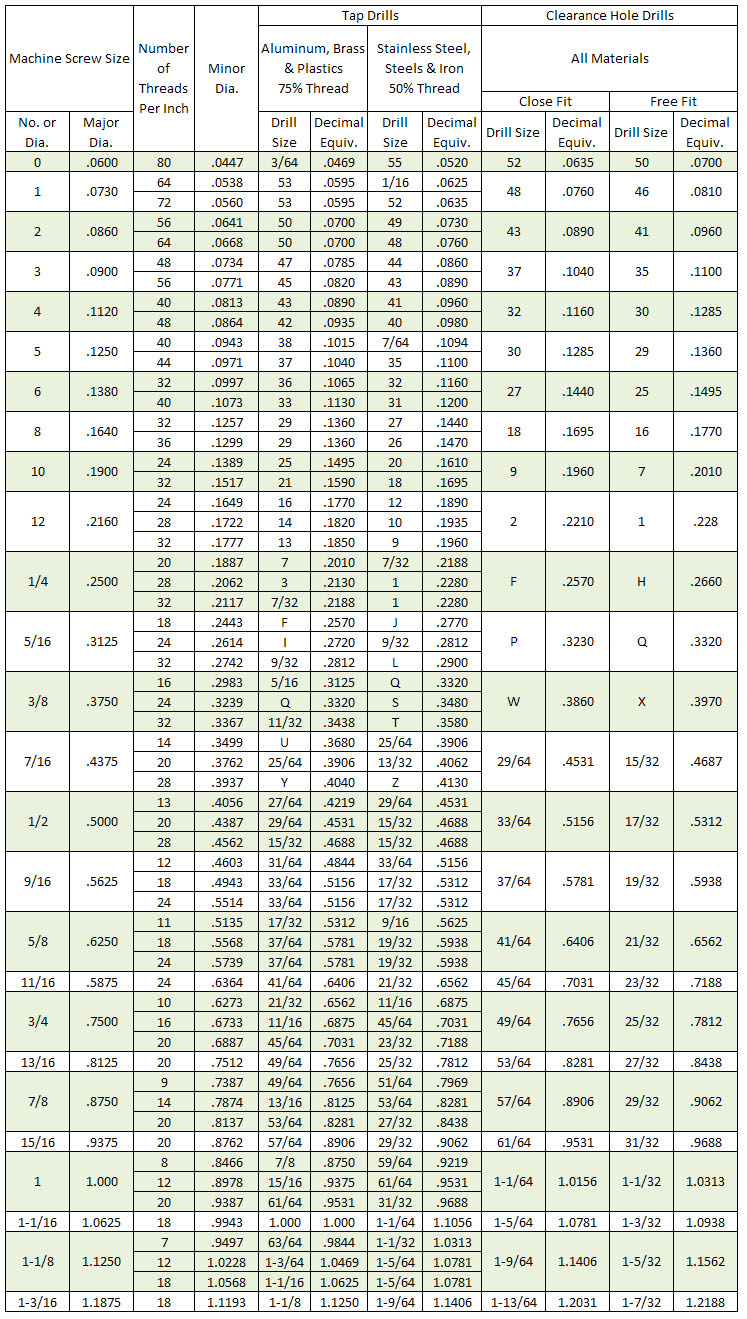

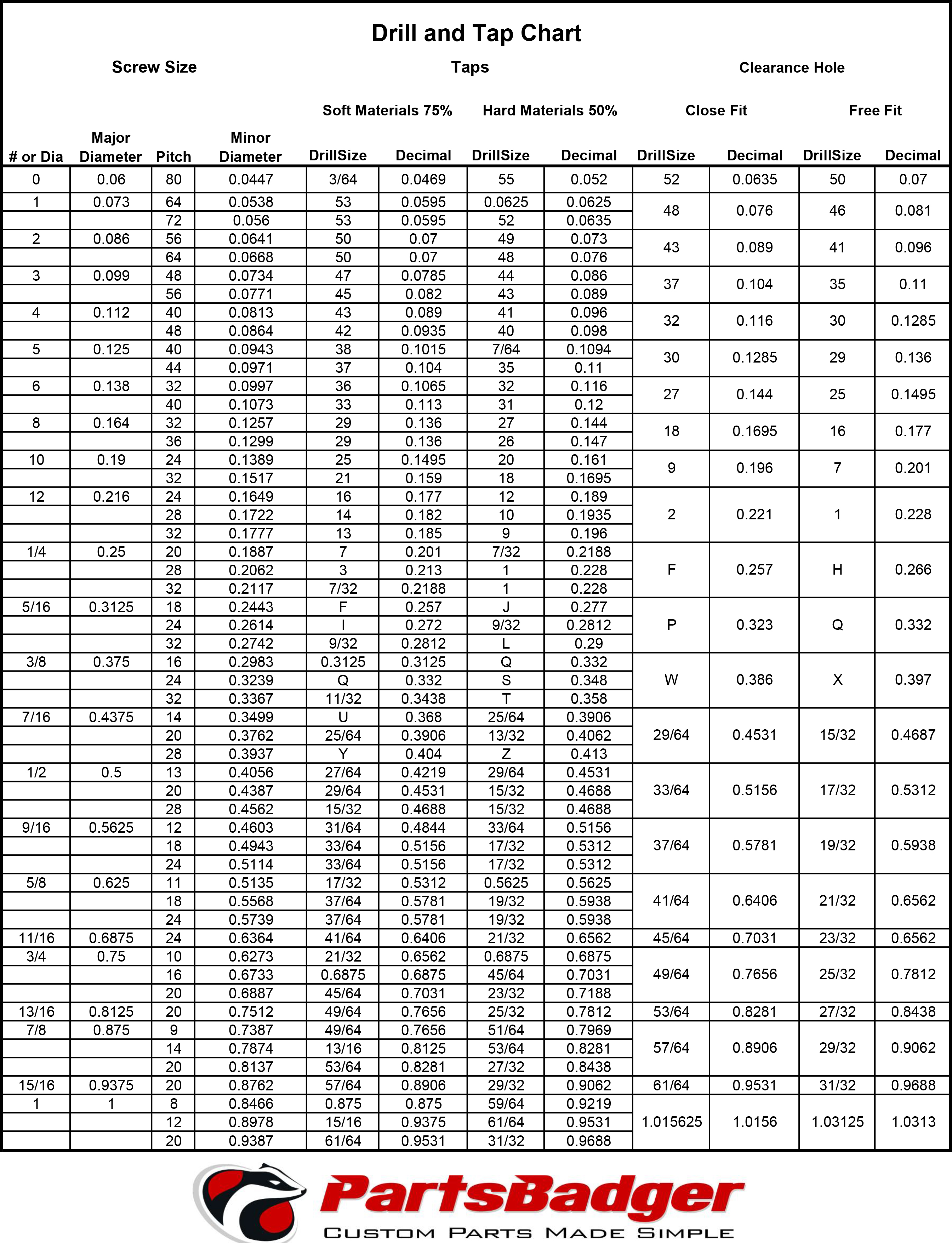

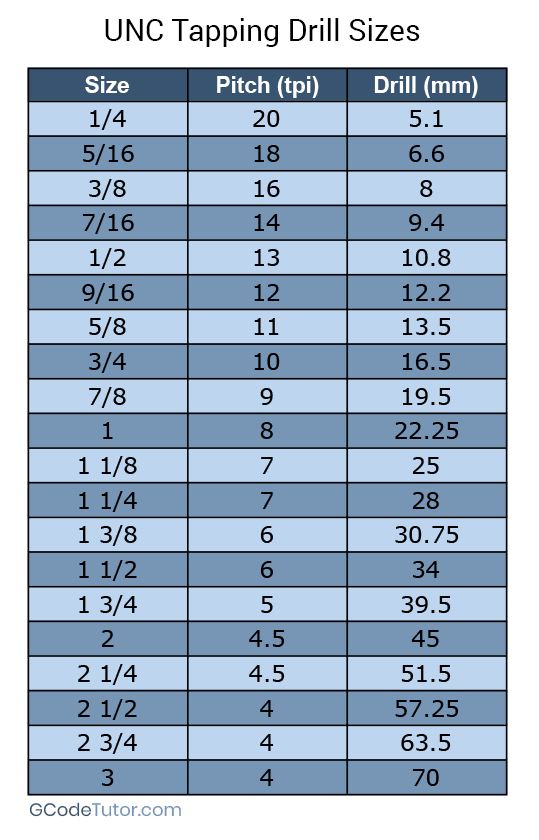

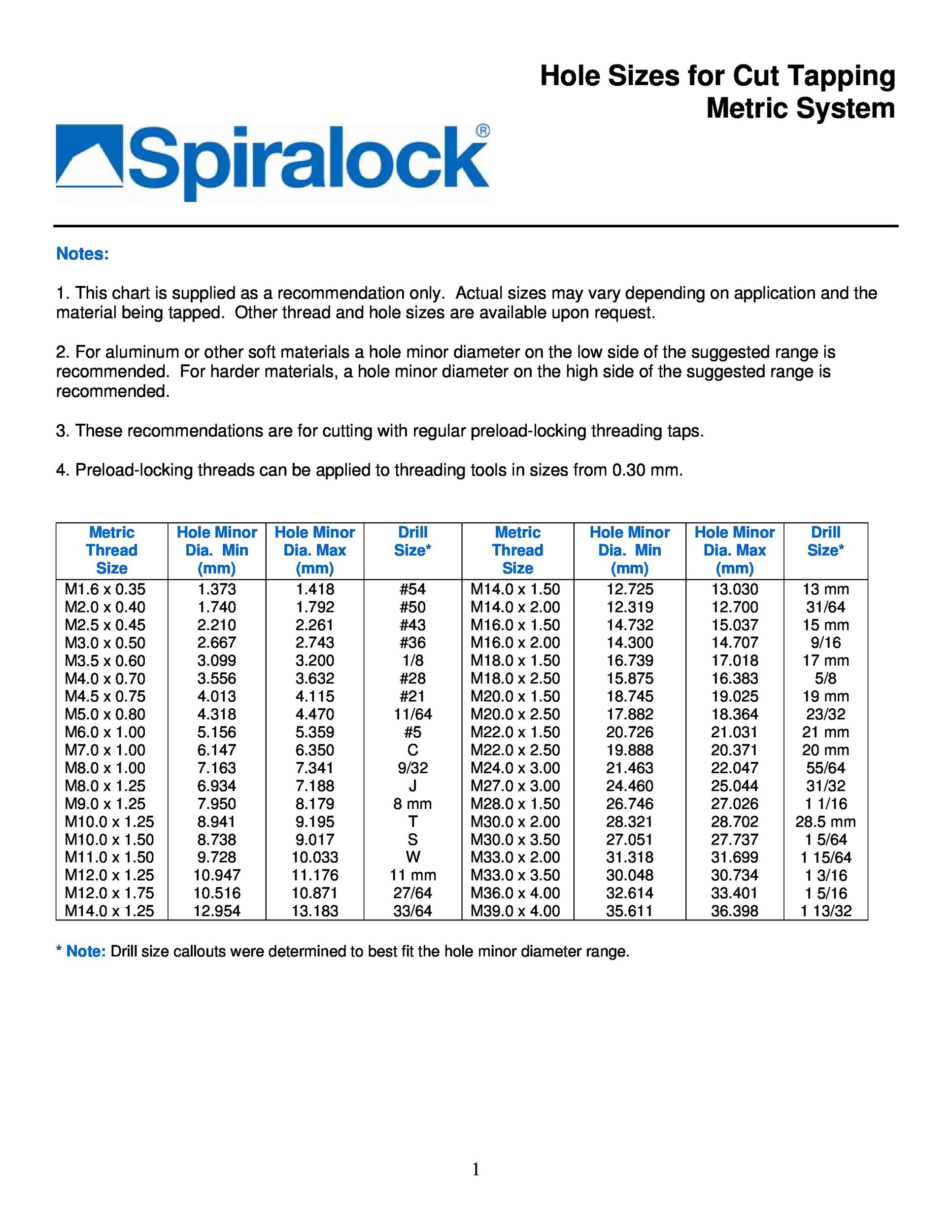

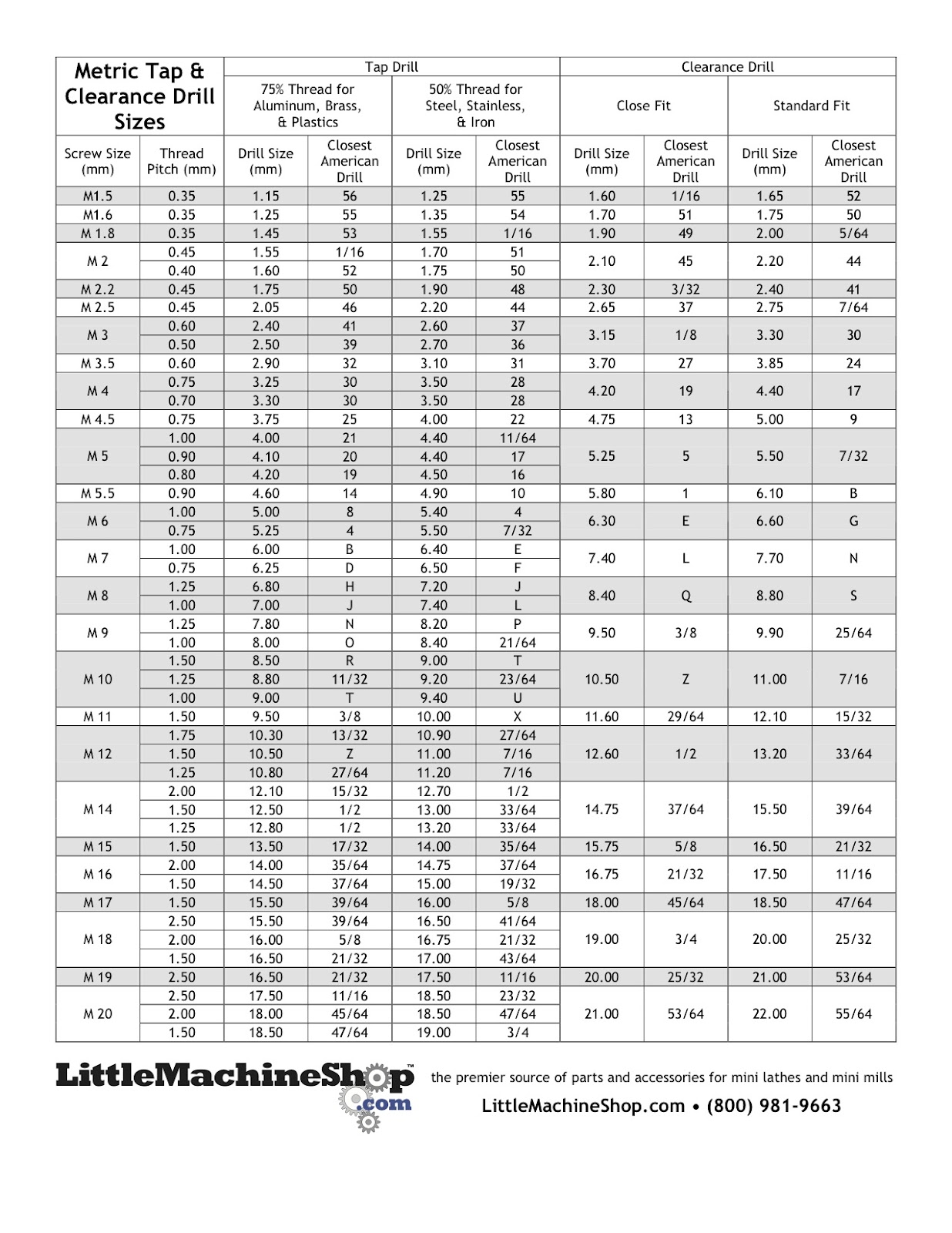

Tap And Drill Chart Metric - Web a drill and tap chart is what specifies the right size of drill bit that one can use to create the correct sized opening that would complement tap dimensions. Web below is a comprehensive drill and tap size chart for all drills and taps, imperial and metric, up to 36.5 millimetres (1.44 in) in diameter. This tap and clearance drill chart shows tap and clearance drill sizes for standard threads. Tap drill clearance drill 75% thread for aluminum, brass, & plastics 50% thread for steel, stainless, & iron close fit standard fit screw size (mm) thread pitch (mm) drill size (mm) closest american drill drill size (mm) closest american drill drill size (mm) closest american drill drill size (mm) closest. Look up the desired pitch and thread percentage to find the corresponding outer diameter. Drill size (mm) drill size (inch) m1.6 x 0.35: Web metric tap drill charts have the same drill size problem in that they use the same formula as that employed for the obsolete as threads. Basic major dia (mm) basic major dia (inch) mm per thread: Web how to read a tape measure beginners guide. A tap drill chart is key in matching pairs of female and male thread that tightly secure together. No more scratching your head wondering which gauge relates to which size or how to convert inches to mm or vice versa. Web every drill size chart you’ll ever need is in this article! In manufactured parts, holes with female screw threads are often needed; Drill size (mm) drill size (inch) m1.6 x 0.35: Web metric tap drill charts have. Manufacturing and design data menu. You can find an sae drill and tap chart here. In manufactured parts, holes with female screw threads are often needed; Web every drill size chart you’ll ever need is in this article! Web metric tap & clearance drill sizes. Tap drill clearance drill 75% thread for aluminum, brass, & plastics 50% thread for steel, stainless, & iron close fit standard fit screw size (mm) thread pitch (mm) drill size (mm) closest american drill drill size (mm) closest american drill drill size (mm) closest american drill drill size (mm) closest. Web how to read a tape measure beginners guide. When. Manufacturing and design data menu. Web every drill size chart you’ll ever need is in this article! Basic major dia (mm) basic major dia (inch) mm per thread: Web we have put together a printable pdf of our metric tap drill chart that you can download and print out for your convenience. Web below is a comprehensive drill and tap. 50% thread screw size major dia (mm) mm per thread drill size closest imperial drill size closest imperial drill size closest imperial drill size closest imperial m1.5 x 0.35 1.5 Web every drill size chart you’ll ever need is in this article! A tap drill chart is key in matching pairs of female and male thread that tightly secure together.. A tap drill chart is key in matching pairs of female and male thread that tightly secure together. Drill size (mm) drill size (inch) m1.6 x 0.35: Web table 4 shows the tap and drill chart for metric threads. Web every drill size chart you’ll ever need is in this article! Web tap & clearance drill sizes. Web below is a comprehensive drill and tap size chart for all drills and taps, imperial and metric, up to 36.5 millimetres (1.44 in) in diameter. In manufactured parts, holes with female screw threads are often needed; This tap and clearance drill chart shows tap and clearance drill sizes for standard threads. Basic major dia (mm) basic major dia (inch). 50% thread screw size major dia (mm) mm per thread drill size closest imperial drill size closest imperial drill size closest imperial drill size closest imperial m1.5 x 0.35 1.5 In both iso and un thread series, having a range of useful drill sizes allows designers and machinists to tailor effective thread depth for long holes, various materials and thread. Web below is a comprehensive drill and tap size chart for all drills and taps, imperial and metric, up to 36.5 millimetres (1.44 in) in diameter. Web every drill size chart you’ll ever need is in this article! Drill size (mm) drill size (inch) m1.6 x 0.35: Web table 4 shows the tap and drill chart for metric threads. Drill. Tap drill clearance drill 75% thread for aluminum, brass, & plastics 50% thread for steel, stainless, & iron close fit standard fit screw size (mm) thread pitch (mm) drill size (mm) closest american drill drill size (mm) closest american drill drill size (mm) closest american drill drill size (mm) closest. Manufacturing and design data menu. Web how to read a. In manufactured parts, holes with female screw threads are often needed; Web tap & clearance drill sizes. Web metric tap drill charts have the same drill size problem in that they use the same formula as that employed for the obsolete as threads. Web 52 rows metric tap chart tap drill clearance drill aluminum, brass, plastics steel, stainless steel, iron close fit. Web we have put together a printable pdf of our metric tap drill chart that you can download and print out for your convenience. Web metric tap & clearance drill sizes. When drilling and tapping a hole you need to drill your workpiece to the right size and in order to tap your workpiece to the correct size. You can find an sae drill and tap chart here. This tap and clearance drill chart shows tap and clearance drill sizes for standard threads. They accept male screws to facilitate the building and fastening of a finished assembly. 50% thread screw size major dia (mm) mm per thread drill size closest imperial drill size closest imperial drill size closest imperial drill size closest imperial m1.5 x 0.35 1.5 Web table 4 shows the tap and drill chart for metric threads. In both iso and un thread series, having a range of useful drill sizes allows designers and machinists to tailor effective thread depth for long holes, various materials and thread strength requirements. Look up the desired pitch and thread percentage to find the corresponding outer diameter. Tap drill clearance drill 75% thread for aluminum, brass, & plastics 50% thread for steel, stainless, & iron close fit standard fit screw size (mm) thread pitch (mm) drill size (mm) closest american drill drill size (mm) closest american drill drill size (mm) closest american drill drill size (mm) closest. Similar to the unified tap and drill section (see above), use the two formulas below to calculate the necessary size of the drilled hole.

Easy to Operate 12pcs Hex Shank HSS Screw Thread Metric Tap Drill

Standard tap drill size chart tnden

Buy Inch Metric Tap Drill Sizes and Decimal Equivalents Chart

FREE 13+ Sample Tap Drill Chart Templates in PDF Excel

3Pcs Metric Tap Drill Bits Tool Cobalt Plated Hex Shank HSS Screw

Drill Size For Tapping Chart

Drill and Tap Reference Guide by PartsBadger

Tap Drill Charts

Metric Tap Drill Chart

The Flying XS Metric Drill Tap Chart

Web Metric Tap Drill Sizes Metric Tap Tap Drill (Mm) Decimal (Inch) M1.6 X 0.35 1.25.0492 M1.8 X 0.35 1.45.0571 M2 X 0.4 1.60.0630 M2.2 X 0.45 1.75.0689 M2.5 X 0.45 2.05.0807 M3 X 0.5 2.50.0984 M3.5 X 0.6 2.90.1142 M4 X 0.7 3.30.1299 M4.5 X 0.75 3.70.1457 M5 X 0.8 4.20.1654 M6 X 1 5.00.1968 M7 X 1 6.00.2362 M8 X 1.25 6.70.2638 M8 X 1 7.

A Tap Drill Chart Is Key In Matching Pairs Of Female And Male Thread That Tightly Secure Together.

No More Scratching Your Head Wondering Which Gauge Relates To Which Size Or How To Convert Inches To Mm Or Vice Versa.

Drill Size (Mm) Drill Size (Inch) M1.6 X 0.35:

Related Post: