Tig Cup Size Chart

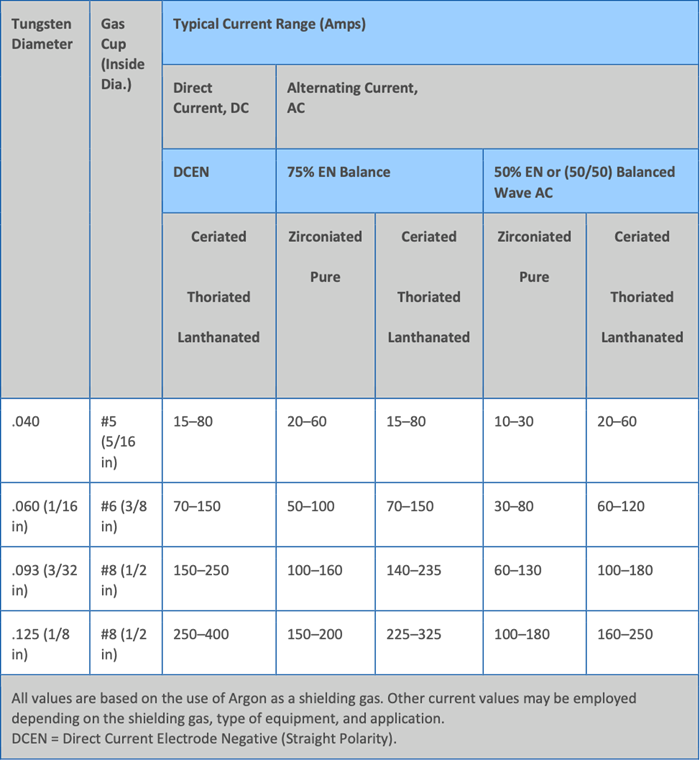

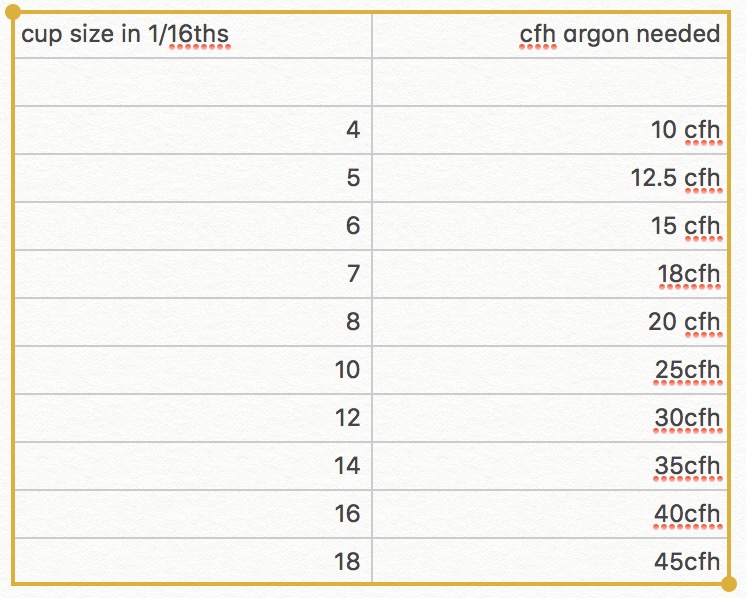

Tig Cup Size Chart - Browse suggested weld parameter settings for tig welding. There also are different sizes for different types of torches, such as a water cooled torch or an air cooled torch. The size you choose depends on various factors, including the welding application, the thickness of the material, and the type of gas used. (800) 426.0877 when tig welding, there are three choices of welding current. In general, the thicker the. When choosing a nozzle size, consider the thickness of the material you’re welding. For example 5 cup = 10 cfh; Web common sizes range from about 1/4 inch (6mm) to over 1 inch (25mm). Since i started welding, it was never logical to me the way gas flow was set for tig welding. Learn how to choose the right tig welding cup size for different materials, thicknesses, and weld areas. Since i started welding, it was never logical to me the way gas flow was set for tig welding. Filler metal must be dry, free of oxides, grease, or other foreign matter. Direct current straight polarity (dcsp), direct current reverse polarity (dcrp), and alternating current with or without high frequency stabilization (achf). Web common sizes range from about 1/4 inch. I was hearing the popular rule cup size x2 = required gas flow rate in cfh. A smaller cup (e.g., 6mm to 10mm) is generally sufficient for welding thinner. 7 cup = 14 cfh; Web learn how to choose the best cup size for tig welding different materials and thicknesses. For example 5 cup = 10 cfh; Web for example, a number 4 cup measures 1/4” across the inside diameter of the opening, a number 5 cup has an opening of 5/16”, a number 6 cup has an opening of 3/8”, a number 7 has an opening of 7/16” and a number 8 cup measures 1/2” across the inside diameter. So make sure you download our charts. In general, the thicker the. What metal are you welding? Web most nozzles used for gtaw are manufactured from ceramic materials, alumina (pink colored) and lava (white colored). Web learn how to choose the best cup size for tig welding different materials and thicknesses. 6 cup = 12 cfh; Web the use of tig welding for aluminum has many advantages for both manual and automatic processes. Web mon jan 11, 2021 1:59 am. Each of these has its applications, advantages,. Web it’s important to choose the right cup size for your tig welding needs. Otherwise, you might find yourself struggling with poor performance and a lot of wasted time. So make sure you download our charts and choose a cup size that’s right for you. A smaller cup (e.g., 6mm to 10mm) is generally sufficient for welding thinner. Web this reference guide will help you quickly understand the weldcraft tig torch product line and the exciting changes that miller has to offer. The exit diameter (diameter closest to the. Direct the flow of shielding gas to your weld with these nozzles. A smaller cup (e.g., 6mm to 10mm) is generally sufficient for welding thinner. Web for example, a number 4 cup measures 1/4” across the inside diameter of the opening, a number 5 cup has an opening of 5/16”, a number 6 cup has an opening of 3/8”, a. 3/8x 32 tungsten electrode conversion chart size suffix inches millimeters 20.020.5mm. 6 cup = 12 cfh; 7 cup = 14 cfh; Web learn how to choose the best cup size for tig welding different materials and thicknesses. Web tig torch selector chart. Filler metal can be either wire or rod and should be compatible with the base alloy. Otherwise, you might find yourself struggling with poor performance and a lot of wasted time and energy. Tungsten inert gas (tig) welding is the process in which an arc is formed between a tungsten electrode and the workpiece to join the metals together. Web. Tungsten inert gas (tig) welding is the process in which an arc is formed between a tungsten electrode and the workpiece to join the metals together. In general, the thicker the. Web but there are also a lot of very skilled tig welders who prefer a simple standard #5 cup for certain situations…so in this video, i am using a. Web for example, a number 4 cup measures 1/4” across the inside diameter of the opening, a number 5 cup has an opening of 5/16”, a number 6 cup has an opening of 3/8”, a number 7 has an opening of 7/16” and a number 8 cup measures 1/2” across the inside diameter. Direct current straight polarity (dcsp), direct current reverse polarity (dcrp), and alternating current with or without high frequency stabilization (achf). (800) 426.0877 when tig welding, there are three choices of welding current. For example 5 cup = 10 cfh; Web gas tungsten arc welding (gtaw) or tig (tungsten inert gas) welding is an arc welding process that uses a tungsten electrode to produce an electric arc that jumps between it and the work. I was hearing the popular rule cup size x2 = required gas flow rate in cfh. When choosing a nozzle size, consider the thickness of the material you’re welding. Web this reference guide will help you quickly understand the weldcraft tig torch product line and the exciting changes that miller has to offer. Direct the flow of shielding gas to your weld with these nozzles. Web 4 the standard in tig welding toll free: Each of these has its applications, advantages,. What metal are you welding? The exit diameter (diameter closest to the arc) is manufactured in a variety of sizes. Browse suggested weld parameter settings for tig welding. Web a look at each type and its uses will help the operator select the best current type for the job. Web common sizes range from about 1/4 inch (6mm) to over 1 inch (25mm).

TIG Cup Kits Archives KO Welding® Australia

Tig Cup Size Chart

Alumina Nozzle Cups for TIG Welding Torches Series 9/20/25/17/18/26 wi

A Better TIG Experience Hot Rod Network

Tig Welding Cup Size Chart Best Picture Of Chart

Alumina Nozzle Cups for TIG Welding Torches Series 9/20/25 with Gas Le

Tig Welding Cup Size Chart

Tig Welding Cup Size Chart Best Picture Of Chart

Alumina Nozzle Cups for TIG Welding Torches Series 9/20/25/17/18/26

Alumina Nozzle Cups for TIG Welding Torches Series 9/20/25 with Gas Le

The Cups Come In Many Different Sizes.

The Size You Choose Depends On Various Factors, Including The Welding Application, The Thickness Of The Material, And The Type Of Gas Used.

3 Series (10N) Torch Models 17, 18, 26 Thread Pattern:

Web Mon Jan 11, 2021 1:59 Am.

Related Post: